Electrical connection device, terminal block including same, photovoltaic power generation system, and electrical appliance

一种电连接装置、端子台的技术,应用在连接装置的零部件、导电连接、电部件连接等方向,能够解决难以确认螺栓紧固连接情况等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

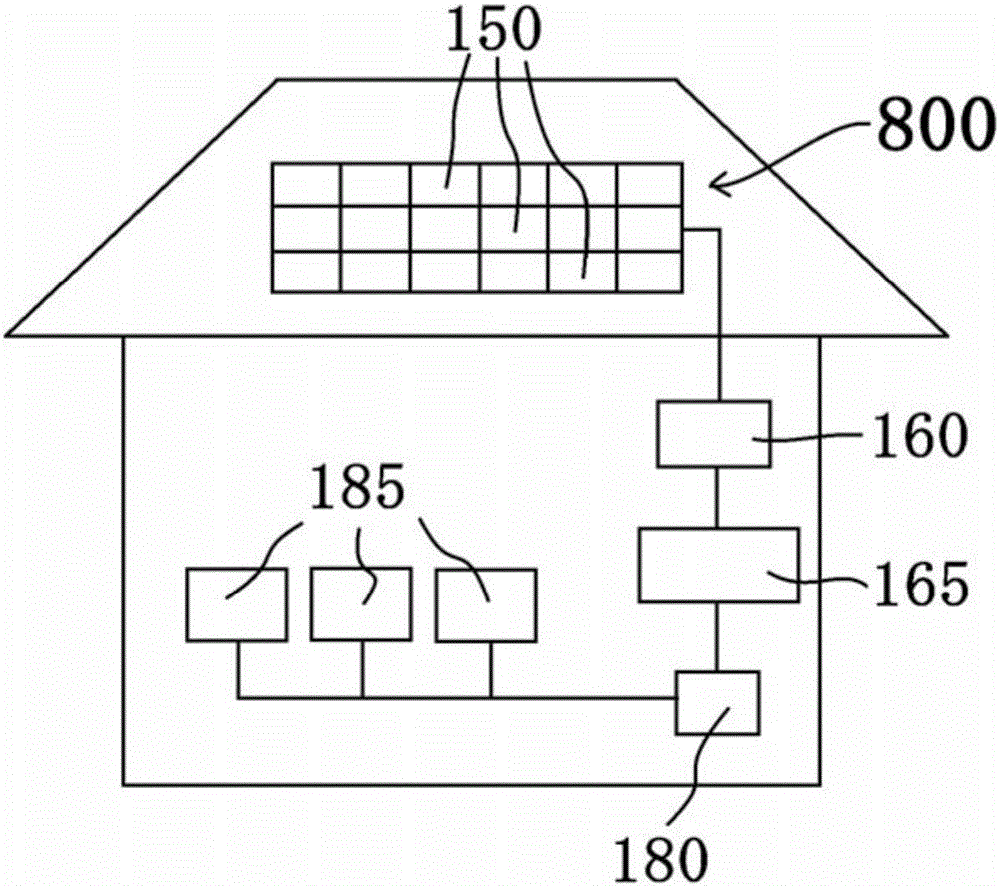

[0096] figure 1 It is a schematic diagram of the structure of the solar power generation system 800 provided with the terminal block 110 of the electrical connection device 100 of this embodiment. Such as figure 1 As shown, the solar power generation system 800 includes, for example, a plurality of solar battery modules 150 installed on the roof of a house, a junction box 160, and a power conditioner 165 that converts DC power generated by the solar battery modules 150 into AC power. In addition, the electric power generated by the solar power generation system 800 is supplied to various electric devices 185 via the switchboard 180 . In the present embodiment, all solar battery modules 150 including a plurality of solar battery cells are arranged on the same surface. In addition, the plurality of solar cell modules 150 are electrically connected in series or in parallel to each other via the electrical connection device 100 .

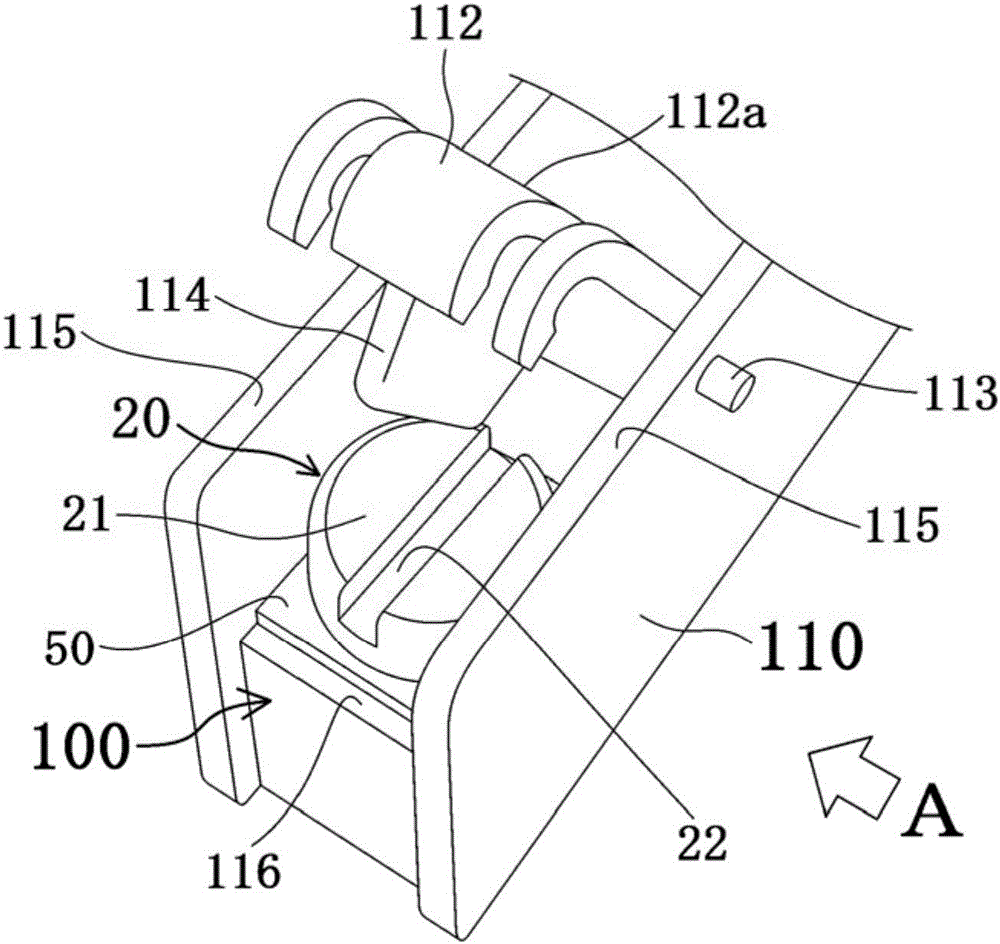

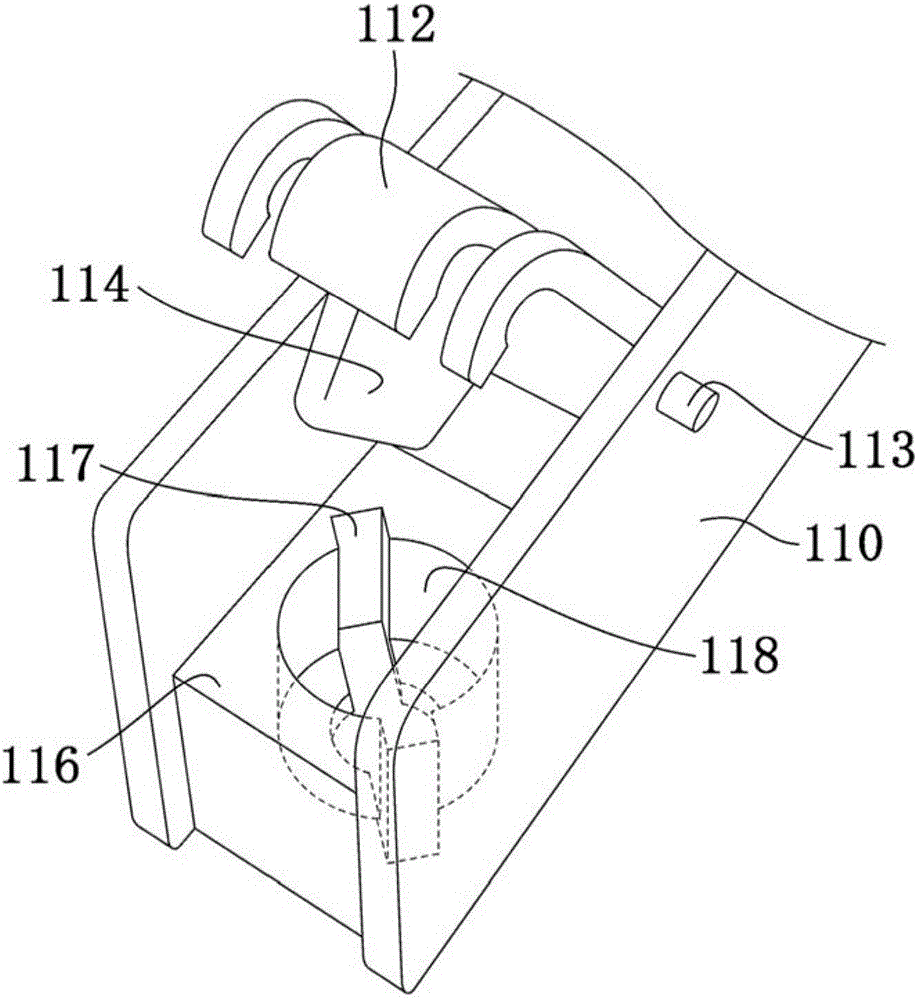

[0097] figure 2 It is a perspective view s...

no. 2 approach

[0115] In this embodiment, the electrical connection device of the first embodiment is identical to the electrical connection device of the first embodiment except that the screw 20 of the first embodiment, the cover body 112 included in the terminal block 110, and the mechanism for changing the biasing force of the coil spring 40 are changed. 100 and the terminal block 110 are the same. Therefore, descriptions of portions overlapping with those of the first embodiment are omitted.

[0116] Figure 12A It is a front view, a left side view, and a vertical cross-sectional view (more specifically, Figure 12A A vertical cross-sectional view of the center of the body portion 224 in the depth direction of the paper). in addition, Figure 12B It is a perspective view showing the shape of the bolt 220 of this embodiment. in addition, Figure 13 to Figure 15 Each is a partial side sectional view for explaining the fastening and connection process of the bolt 220 of the electrical c...

no. 3 approach

[0132] In this embodiment, a bolt 320 is used instead of the bolt 20 in the first embodiment. Figure 20 It is a perspective view corresponding to FIG. 4 showing the shape of the bolt 320 of this embodiment.

[0133] Such as Figure 20 As shown, the bolt 320 of this embodiment has a head 321 and a body 24 having the same structure as the body 24 of the bolt 20 of the first embodiment, and a hole for inserting a screwdriver to rotate the bolt 320 is formed on the head 321 . The slot 322 for a cross-shaped screwdriver. The bolt 320 of this form can also obtain at least some of the effects of the first embodiment.

[0134] However, in order for the operator to visually check the screwing state of the bolt more easily, it is more preferable to use a linear screwdriver groove than to use a cross-shaped screwdriver groove 322 . In addition, of course, in the second embodiment or the fourth embodiment described later, a head having a cross-shaped screwdriver groove 322 formed ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com