Guide rolling wheel for working table

A technology of guiding rollers and workbenches, which is applied in the manufacture of tools and presses, etc. It can solve the problems of the guide rail affecting normal walking and affecting the service life of the guide rail, and achieves the effect of simple structure and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

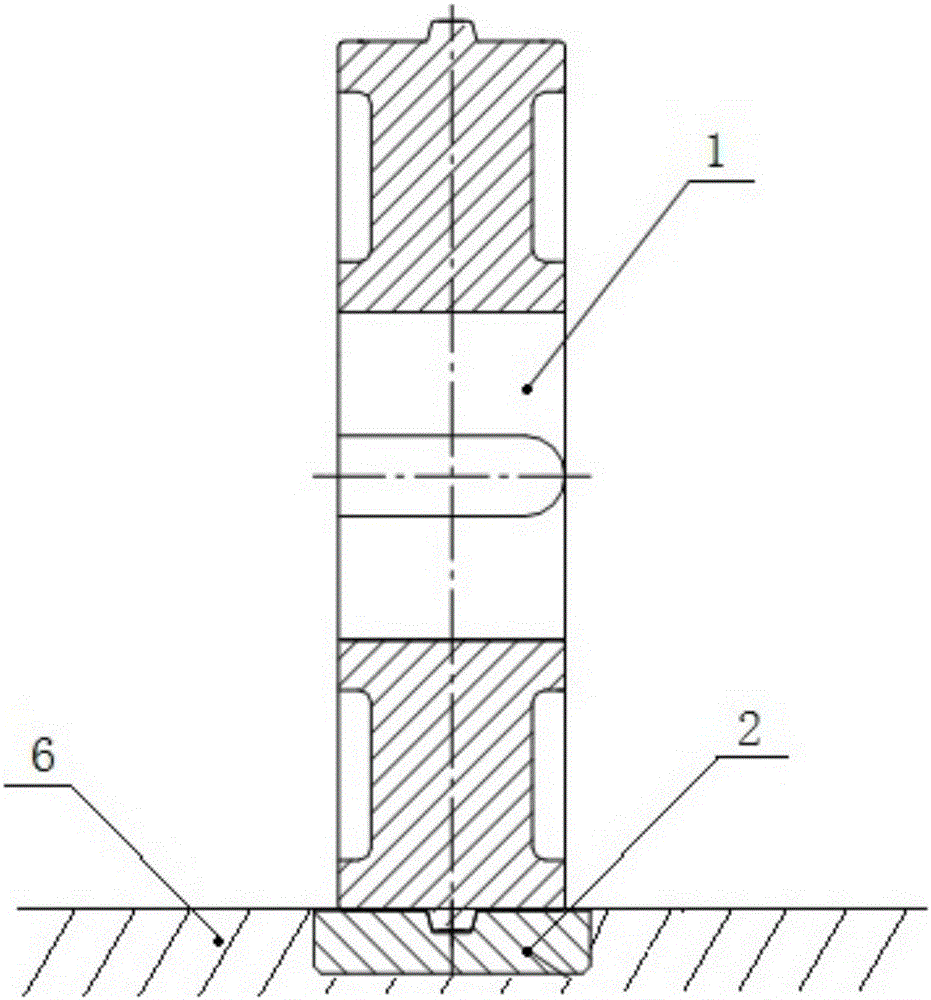

[0015] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

[0016] The present invention comprises guide roller 1 and guide rail 2.

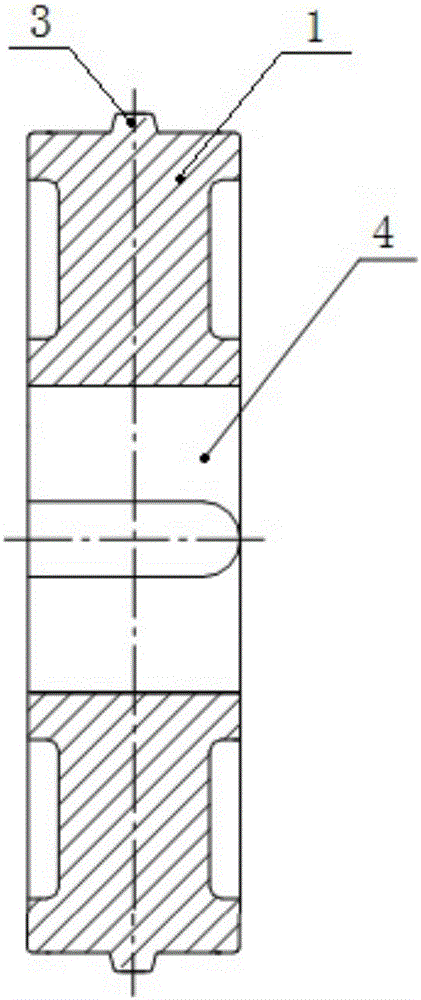

[0017] figure 1 Shown is a schematic structural view of the guide roller of the present invention.

[0018] The middle part of the outer ring of the guide roller 1 is provided with a circumferential convex line 3 adapted to the guide groove 5, and the two sides of the circumferential convex line 3 are guide surfaces.

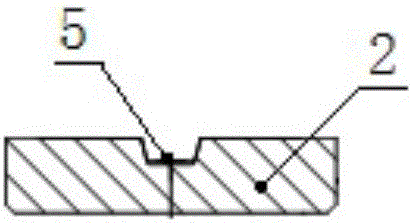

[0019] figure 2 Shown is a structural schematic diagram of the guide rail of the present invention.

[0020] The middle part of the guide rail 2 is provided with a guide groove 5 .

[0021] The cross-section of the guide groove 5 is an inverted trapezoidal structure, wherein the inclined surfaces on both sides are working surfaces, the angle α between the inclined surfaces is 30°, and the surface is heat-treated.

[0022] The depth of the guide groove 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com