Safe transferring barrel of liquid nitrogen

A safe and liquid pipetting technology, applied in liquid distribution, transportation or transfer devices, special distribution devices, packaging, etc., can solve the problems of uncontrollable pouring volume, easy overflow or splash, operator injury, etc., to increase The difficulty of taking and pouring liquid, increasing the volume of liquid taken, and avoiding the effect of tilting the bucket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the scope expressed in the examples.

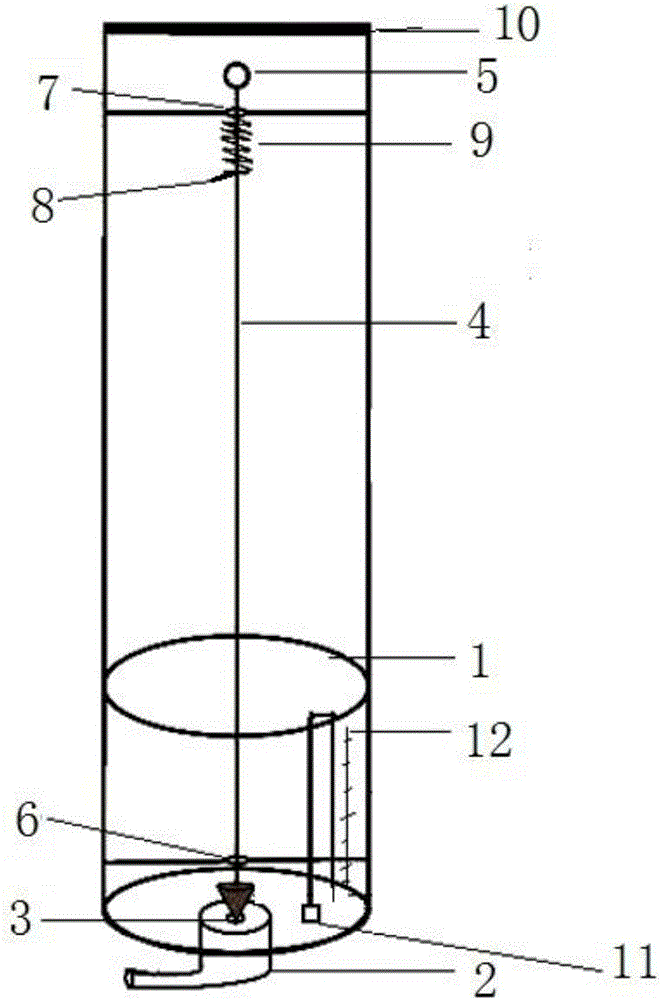

[0020] like figure 1 As shown, a liquid nitrogen safety pipetting bucket, the bottom of the barrel body 1 is equipped with a diversion tube 2, the junction of the diversion tube 2 and the barrel body 1 is provided with a conical plug 3, and the top of the conical plug 3 passes through the vertical rod 4 is connected to the pull ring 5, and the pull ring 5 is positioned above the staving.

[0021] The barrel body 1 is provided with a first limiting ring 6, which is located above the conical plug 3, and its inner diameter is smaller than the outer diameter of the bottom of the conical plug 3, and the vertical rod 4 passes through the first limiting ring 6.

[0022] The barrel body 1 is provided with a second limit ring 7, the vertical bar 4 passes through the second limit ring 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com