Combined type ship lock structure

A combined, ship lock technology, used in ship locks, ship lifting devices, climate change adaptation, etc., to achieve the effect of reducing thickness, reducing stacking area, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

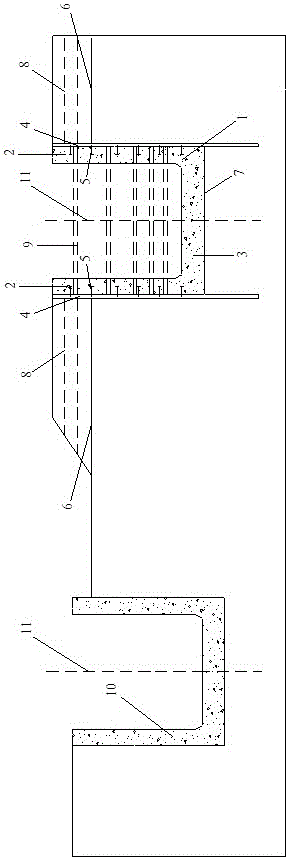

[0024] figure 1 As shown, the present invention is a combined ship lock structure, including integral structure 1, lock wall 2, floor 3, sheet pile 4, connector 5, original ground 6, foundation surface 7, backfill soil 8, and lateral support 9 , Ship lock 10 and central axis 11 have been built.

[0025] In a specific example, such as figure 1 As shown, the central axis 11 of the combined ship lock of the present invention is very close to the central axis of the built ship lock 10. The sheet piles 4, connectors 5, and lateral supports 9 of the combined ship lock need to be prefabricated before construction, and the sheet piles 4 are constructed by piling. The device taps into the preset elevation. The soil between the two rows of sheet piles 4 is excavated on the original ground 6 , and part of the excavated soil can be used as backfill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com