Piston cooling nozzle control method and system

A technology of piston cooling nozzles and control methods, which is applied in liquid cooling, engine cooling, engine components, etc., and can solve problems such as increased fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

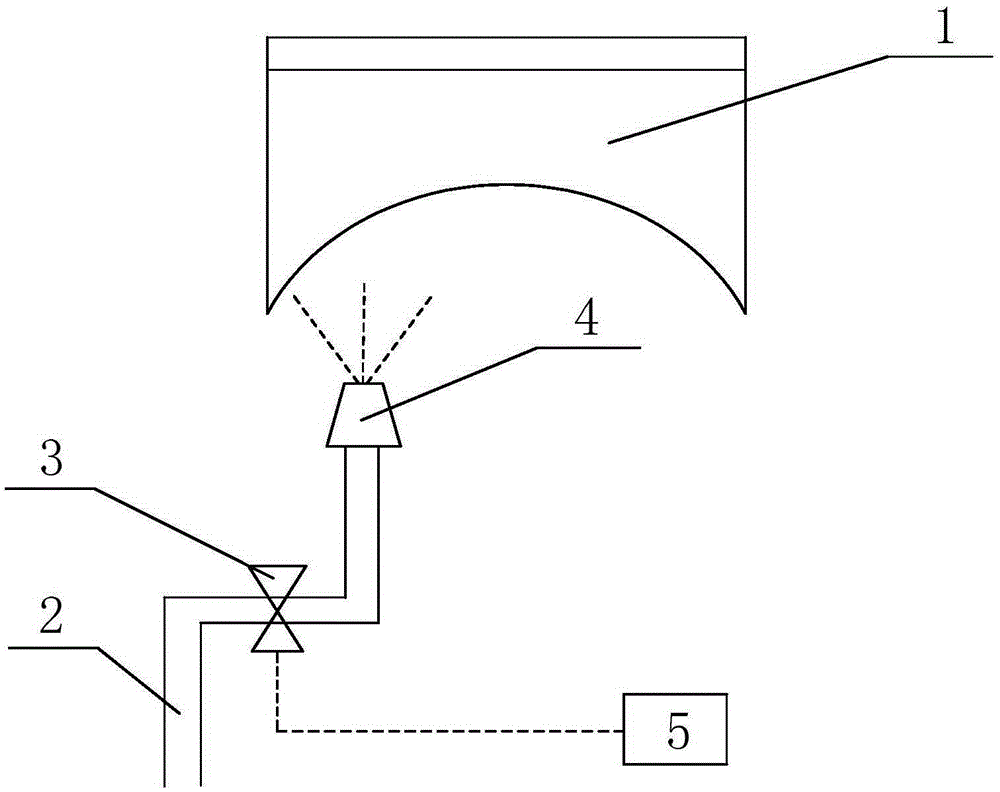

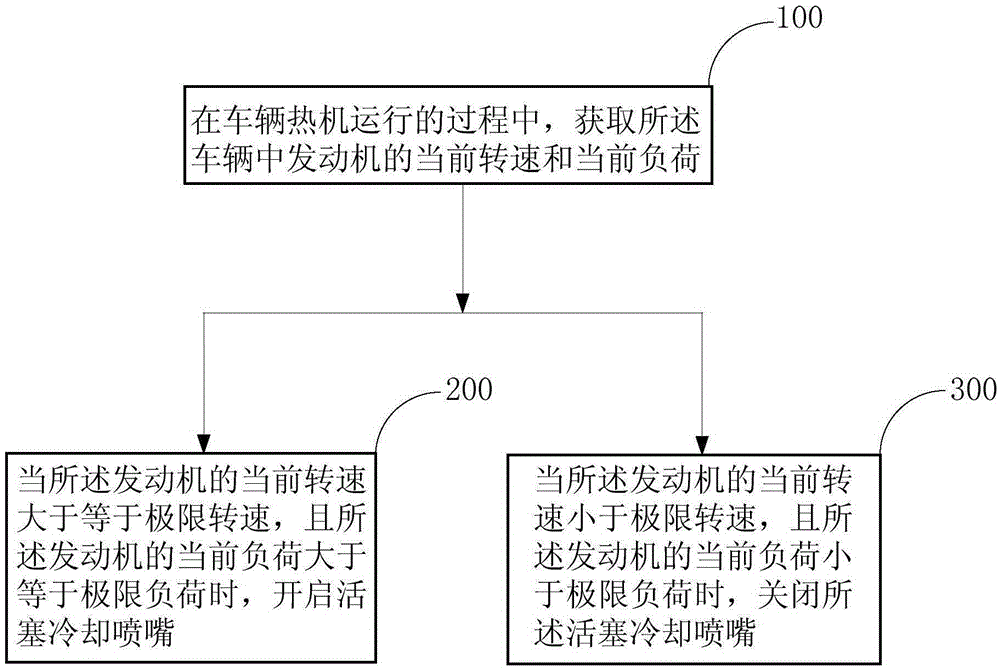

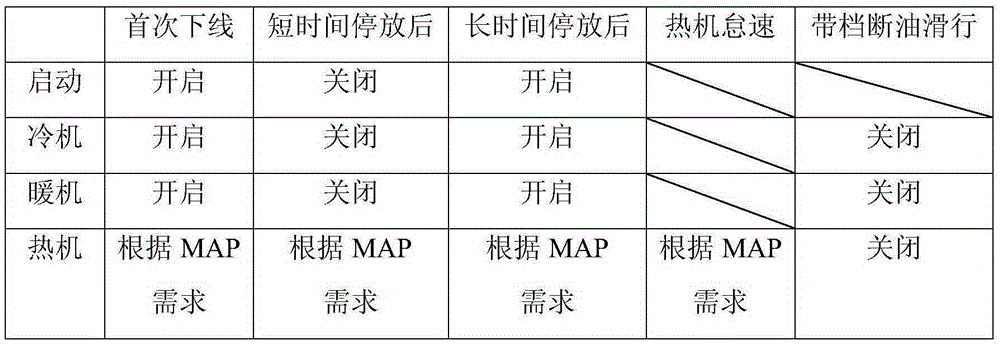

[0068] see figure 1 and figure 2 , an embodiment of the present invention provides a piston cooling nozzle control method, including:

[0069] Step 100, during the warm-up operation of the vehicle, obtain the current rotational speed and current load of the engine in the vehicle;

[0070] Step 200, when the current speed of the engine is greater than or equal to the limit speed, and the current load of the engine is greater than or equal to the limit load, turn on the piston cooling nozzle 4;

[0071] Step 300, when the current speed of the engine is less than the limit speed and the current load of the engine is less than the limit load, close the piston cooling nozzle 4;

[0072] Among them, the limit speed is the speed of the engine when the piston 1 of the engine is at the thermal load limit (reaching the thermal load limit of the piston 1 means that the piston 1 may cause the engine to knock), and the limit load is that the piston 1 is at the thermal load limit. Engin...

Embodiment 2

[0088]Embodiment 2 of the present invention provides a piston cooling nozzle control system, which is controlled by the piston cooling nozzle control method provided in Embodiment 1. The piston cooling nozzle control system includes a control unit 6, and the control unit 6 is used for: in the process of vehicle heat engine operation Among them, when the current speed of the engine is greater than or equal to the limit speed, and the current load of the engine is greater than or equal to the limit load, the piston cooling nozzle 4 is opened; when the current speed of the engine is less than the limit speed, and the current load of the engine is less than the limit load, the piston is closed Cooling nozzle 4; Wherein, the limit speed is the speed of the engine when the piston 1 is at the thermal load limit, and the limit load is the load of the engine when the piston 1 is at the thermal load limit.

[0089] During specific implementation, lubricating oil can be used as the coolan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com