A Component Locating Method Based on Template Matching

A positioning method and template matching technology, applied in the field of image processing, can solve the problems of poor versatility and low illumination robustness, and achieve the effect of stability and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0056] Specific implementation mode 1. Combination figure 1 Describe this embodiment, a template matching-based component positioning method described in this embodiment, the specific steps of the method are:

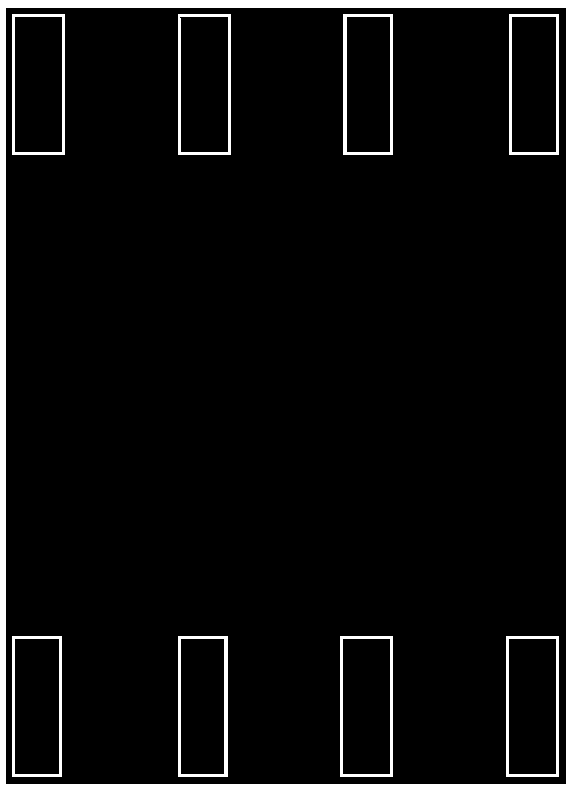

[0057] Step 1. Create a template image for the component to be positioned. The pixel gray value of the pin edge of the component in the template image is a, and the background gray value is 0; a is a positive integer; the template image is as follows: figure 1 shown;

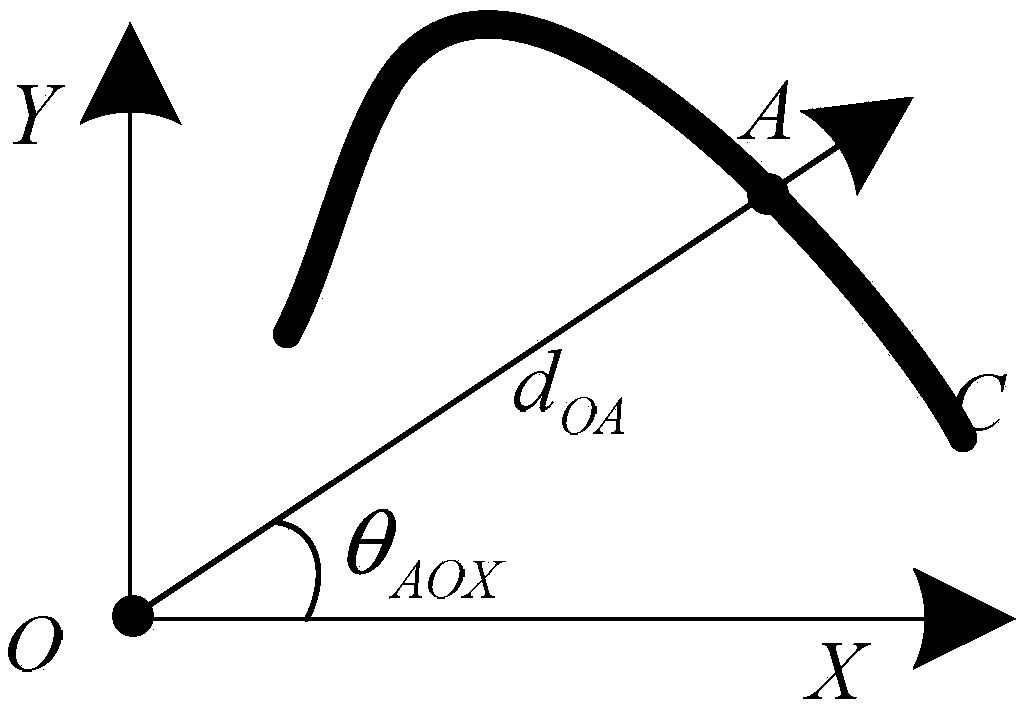

[0058] Step 2, taking the center of the template image as the origin to establish a rectangular coordinate system to obtain the vector field of the template image;

[0059] The information of the template image includes the distance between the edge point of the template image and the coordinate origin and the angle between the line between the edge point of the template image and the coordinate origin and the Cartesian coordinate system X axis of the template image;

[0060] Step 3, use an industrial...

specific Embodiment approach 2

[0078] Specific embodiment 2. This embodiment is a further description of a component positioning method based on template matching described in specific embodiment 1. The specific steps of the method are: in step 2, establish a right angle with the center of the template image as the origin coordinate system, extract template image information, and obtain the vector field of the template image as follows:

[0079] First, use the image processing method to obtain template component information: component size, pin number, pin length, pin width, pin type and pin location;

[0080] Secondly, use template component information to establish a pin edge image, and the set of non-zero pixel points in the pin edge image is U={u m =(x m ,y m )}, where u m is the mth point in the point set, (x m ,y m ) is the coordinate of the mth point, and the unit is pixel;

[0081] Then, establish a Cartesian coordinate system with the center of the template image as the origin, let C be an ed...

specific Embodiment approach 3

[0086] Specific embodiment three. This embodiment is a further description of a template matching-based component positioning method described in specific embodiment one. The specific method for obtaining the distance image of the component described in step three is:

[0087] Use the edge extraction method: use Sobel, Isotropic, SobelRoberts, Prewitt, Laplacian or Canny operator to extract the edge image of the component;

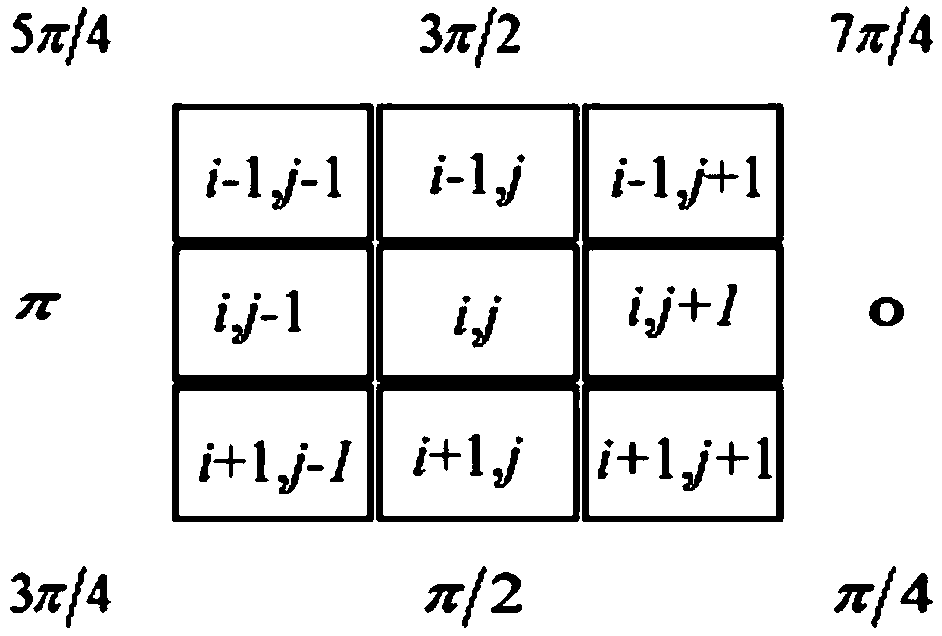

[0088] Using 3-4DT matrix Calculate the distance from each non-zero pixel point in the edge image of the component to the nearest edge point, and express the distance image of the component as DT(x,y).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com