Method for determining reliability growth trend of railway vehicle and predicting fault rate

A rail vehicle and reliability technology, which is applied in the field of system or component reliability growth trend judgment and failure rate prediction, can solve the problems that cannot be given quantitatively and cannot infer the effectiveness of management, etc., and achieve the effect of good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with example the present invention is described in further detail. However, the invention is not limited to the examples given.

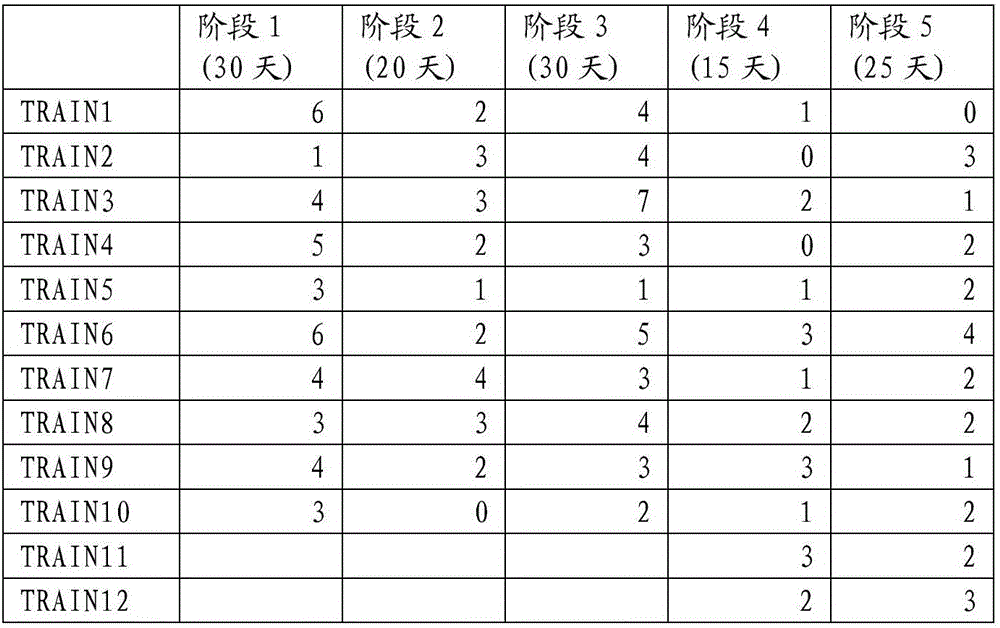

[0051] The technical specification of a certain urban rail transit project stipulates that: from the second year (that is, 366 days) after the train is put into commercial operation, the mean time between failures (MTBF) of the train should not be less than 200 hours. And the faults found in the daily inspection by maintenance personnel. It is stipulated in the technical specification that the trains run 18 hours a day.

[0052] After the train is put into operation, the internal fault statistics of the train are as follows:

[0053]

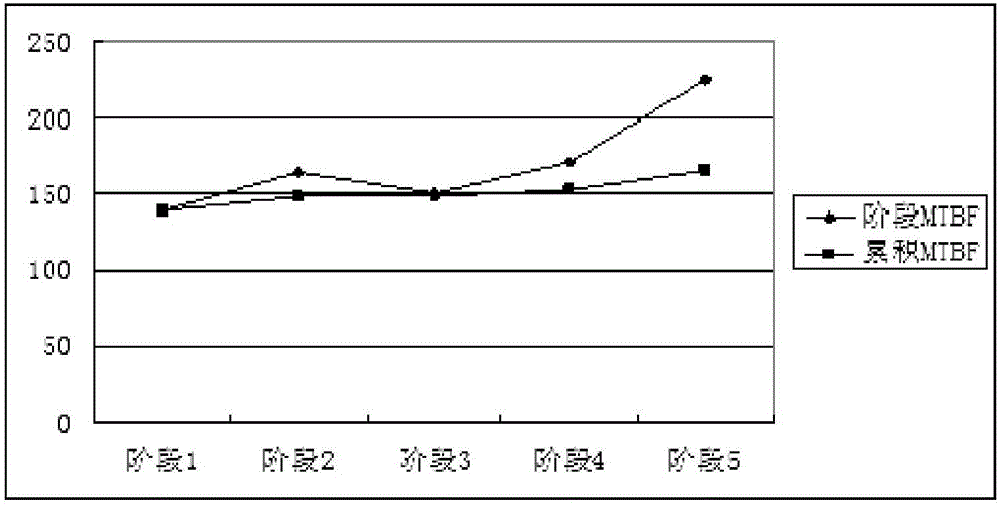

[0054] According to the second step, the third step and the fourth step, the data are arranged in the following table:

[0055]

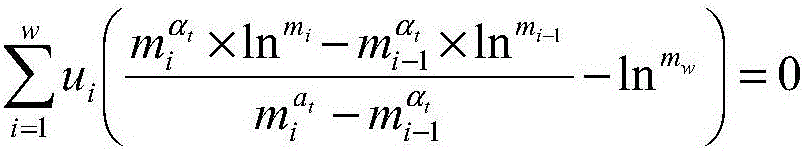

[0056] The fifth step is to calculate the reliability growth factor a t

[0057] Substitute the data into the formula:

[0058] The reliability gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com