Prefabricated concrete structure construction management method and system based on BIM technology

A concrete structure and management method technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as limited stacking space for components, complicated information for multiple acceptance of components, and the need to strengthen communication and cooperation in component supply chains to achieve integration Information, remote monitoring of component quality and construction progress, and the effect of strengthening information exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

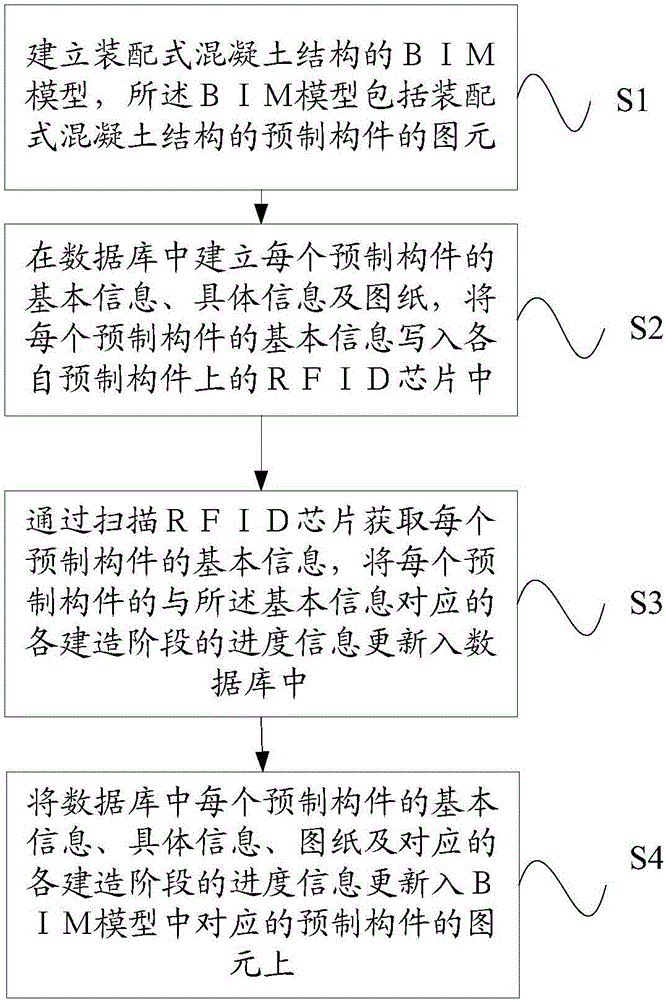

[0038] Such as figure 1 As shown, the present invention provides a method for managing the construction of prefabricated concrete structures based on BIM technology, including:

[0039] Step S2, establishing the basic information, specific information and drawings of each prefabricated component in the database, and writing the basic information of each prefabricated component into the RFID chips on the respective prefabricated components;

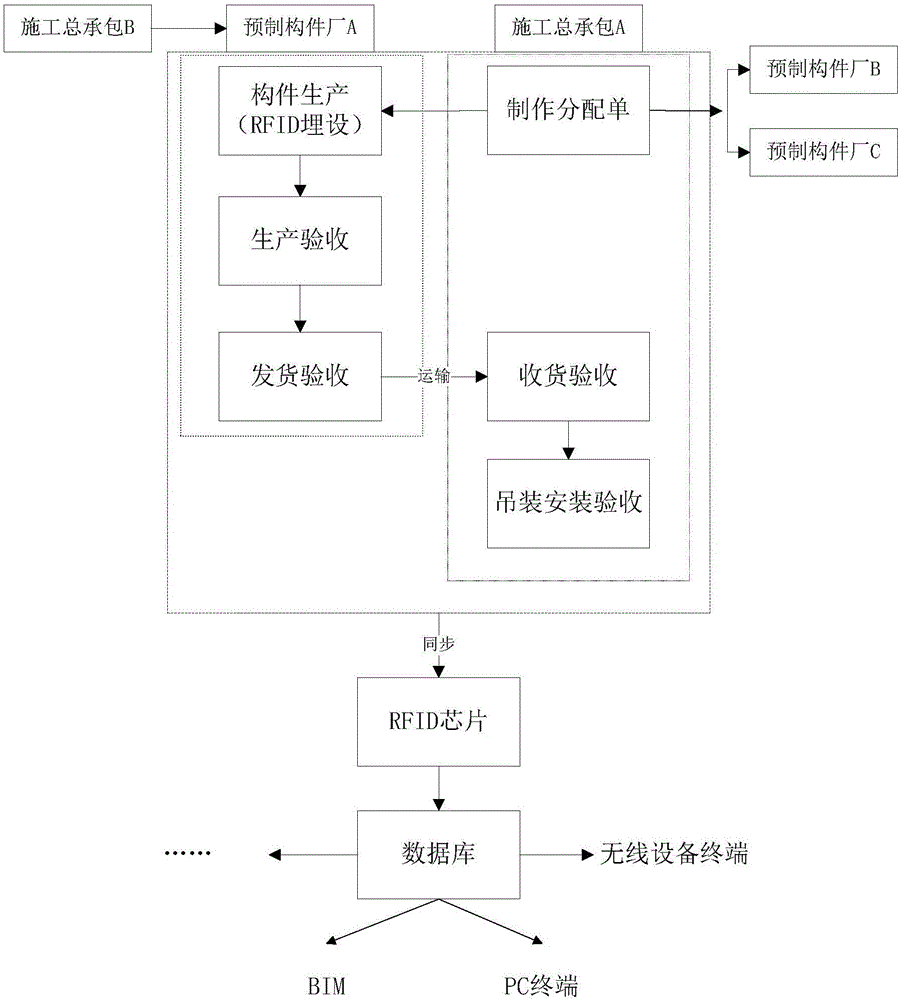

[0040]In step S3, the basic information of each prefabricated component is obtained by scanning the RFID chip, and the progress information of each construction stage corresponding to the basic information of each prefabricated component is updated into the database. Specifically, in the construction of prefabricated concrete structures, timely and effective communication between the construction general contractor and the prefabricated component factory affects the construction quality and construction efficiency. In the context of the r...

Embodiment 2

[0056] The present invention also provides another prefabricated concrete structure construction management system based on BIM technology, including:

[0057] The initialization module is used to establish the basic information, specific information and drawings of each prefabricated component in the database, and write the basic information of each prefabricated component into the RFID chip on the respective prefabricated component;

[0058] The update module is used to obtain the basic information of each prefabricated component by scanning the RFID chip, and update the progress information of each construction stage corresponding to the basic information of each prefabricated component into the database.

[0059] Preferably, it also includes a BIM model module, which is used to establish a BIM model of the prefabricated concrete structure. The BIM model includes the graphic elements of the prefabricated components of the prefabricated concrete structure, and the basic infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com