washing machine

A technology for washing machines and openings, applied in the field of washing machines, which can solve the problems of washing water diffusion and inability to spray washing water, etc., and achieve the effect of improving the ejection force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

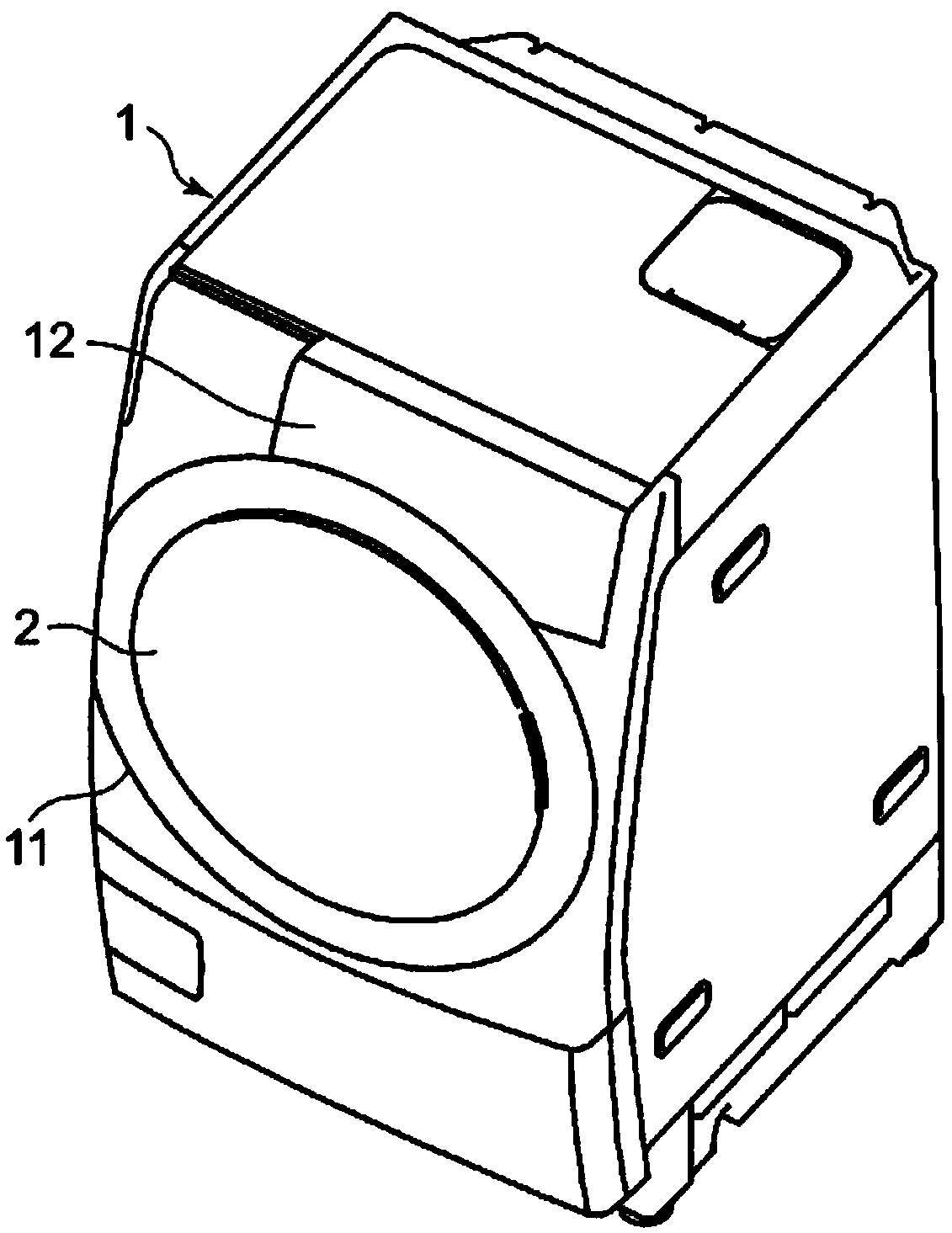

[0031] figure 1 It is a schematic perspective view showing the appearance of a front-loading washing machine as an example of the washing machine according to the first embodiment of the present invention.

[0032] The above-mentioned drum-type washing machine includes an outer case 1 having an outer case opening 11 at the front. A door 2 for opening and closing an opening 11 of the outer case is attached to the front portion of the outer case 1 so as to be rotatable in the left-right direction by hinges. Moreover, the operation display part 12 is provided in the upper part of the front part of the outer case 1. As shown in FIG. The user selects a desired washing course by operating the operation display unit 12 . In addition, the operation display unit 12 displays, for example, the remaining time of the washing program and the like.

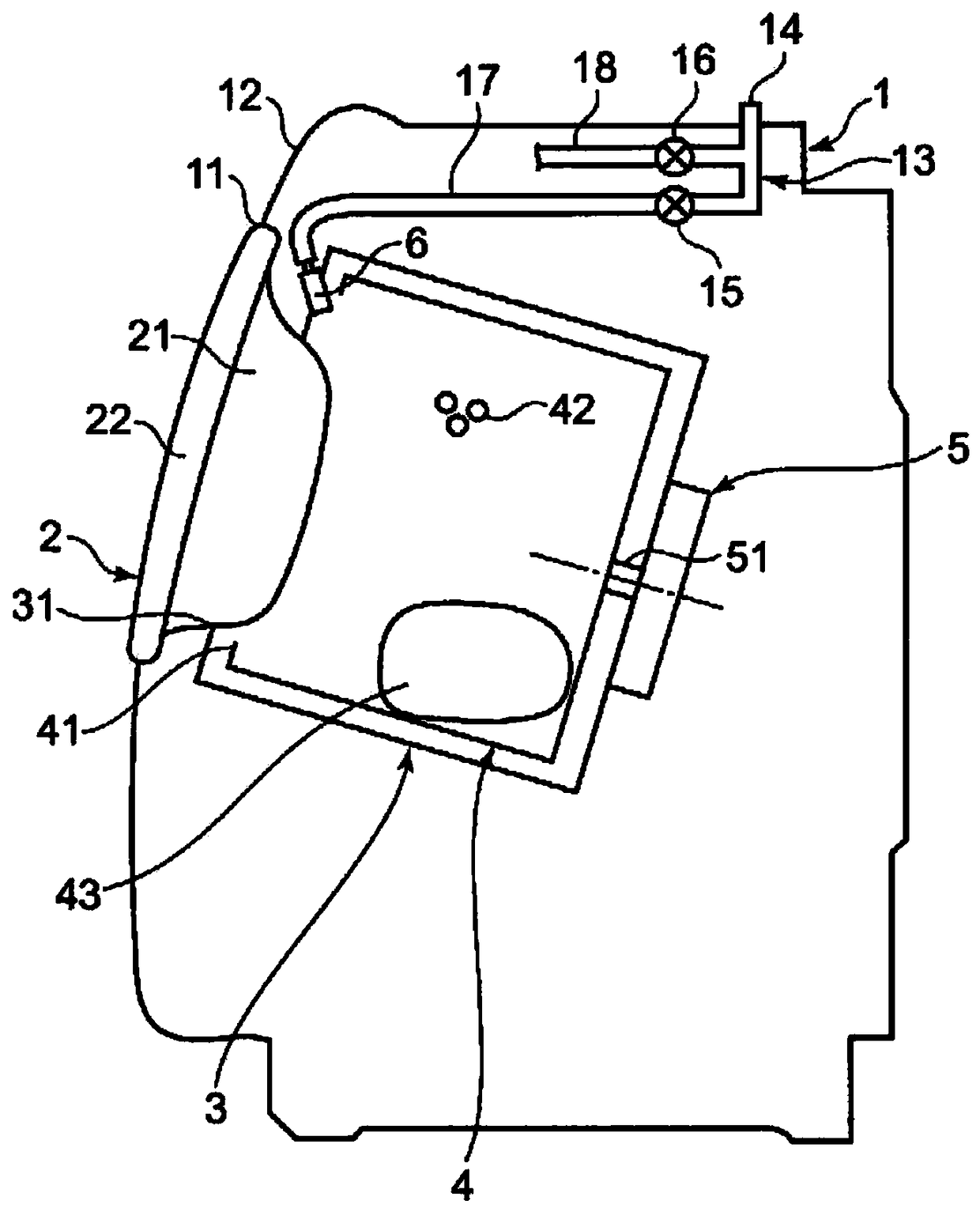

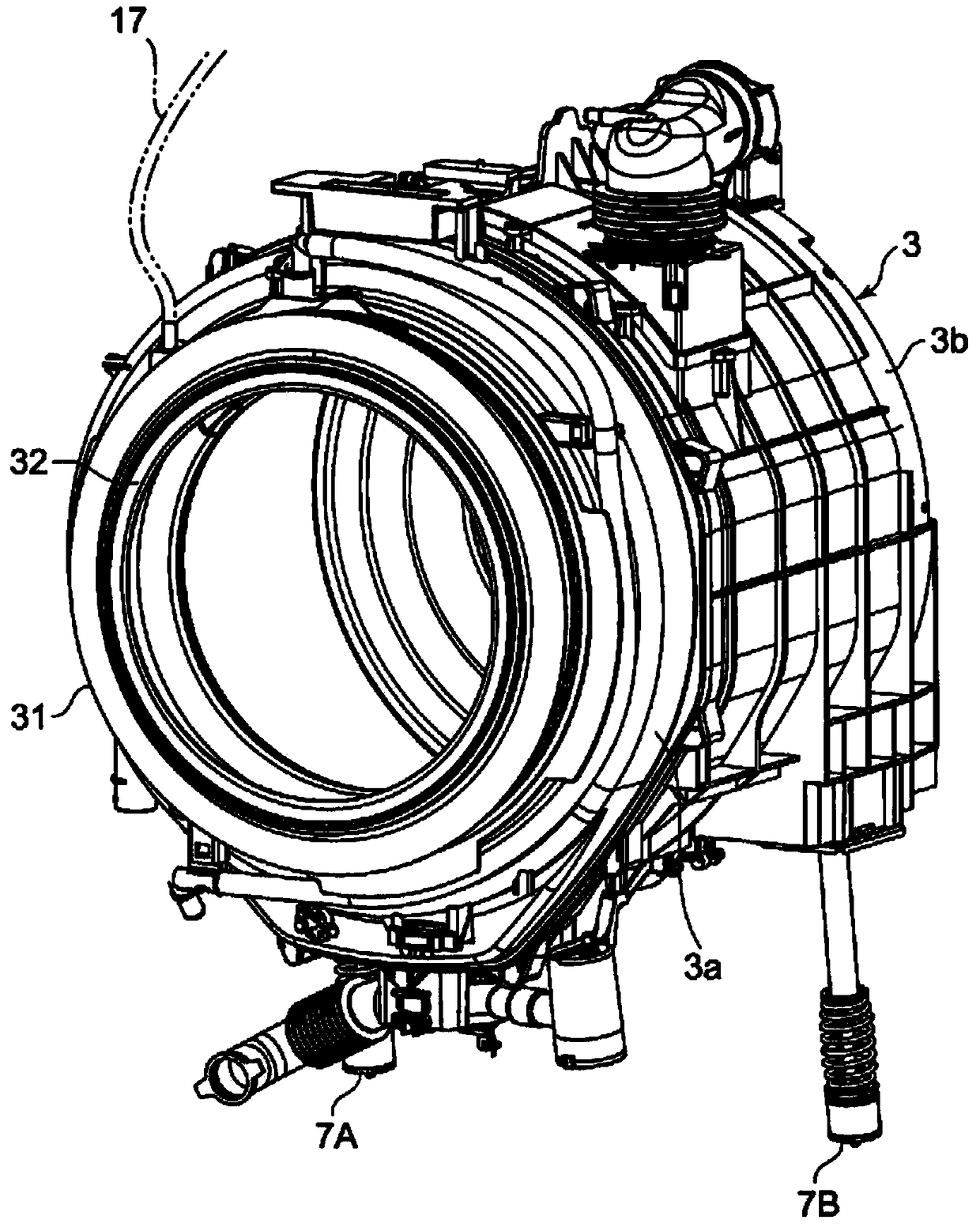

[0033] figure 2 It is a cross-sectional schematic diagram for explaining the structure of the above-mentioned front-loading-type washing m...

no. 2 approach

[0096] In the drum-type washing machine as an example of the washing machine according to the second embodiment of the present invention, the upstream end of the second spout pipe 81 is tightly fitted into the downstream end of the first spout pipe 71 .

no. 3 approach

[0098] In the drum-type washing machine as an example of the washing machine according to the third embodiment of the present invention, one nozzle pipe may be used instead of the first and second nozzle pipes 71 and 81 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com