Self-lubricating gear with oil supply and return functions and sealing assembly

A self-lubricating, gear technology, applied to components with teeth, gear lubrication/cooling, belts/chains/gears, etc., can solve the accuracy and life hazards of gear transmission systems, increase gear oil churning resistance, and mesh tooth surfaces Lack of oil lubrication and other problems, to achieve the effect of good oil leakage prevention, enhanced ejection power, and meet the work requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

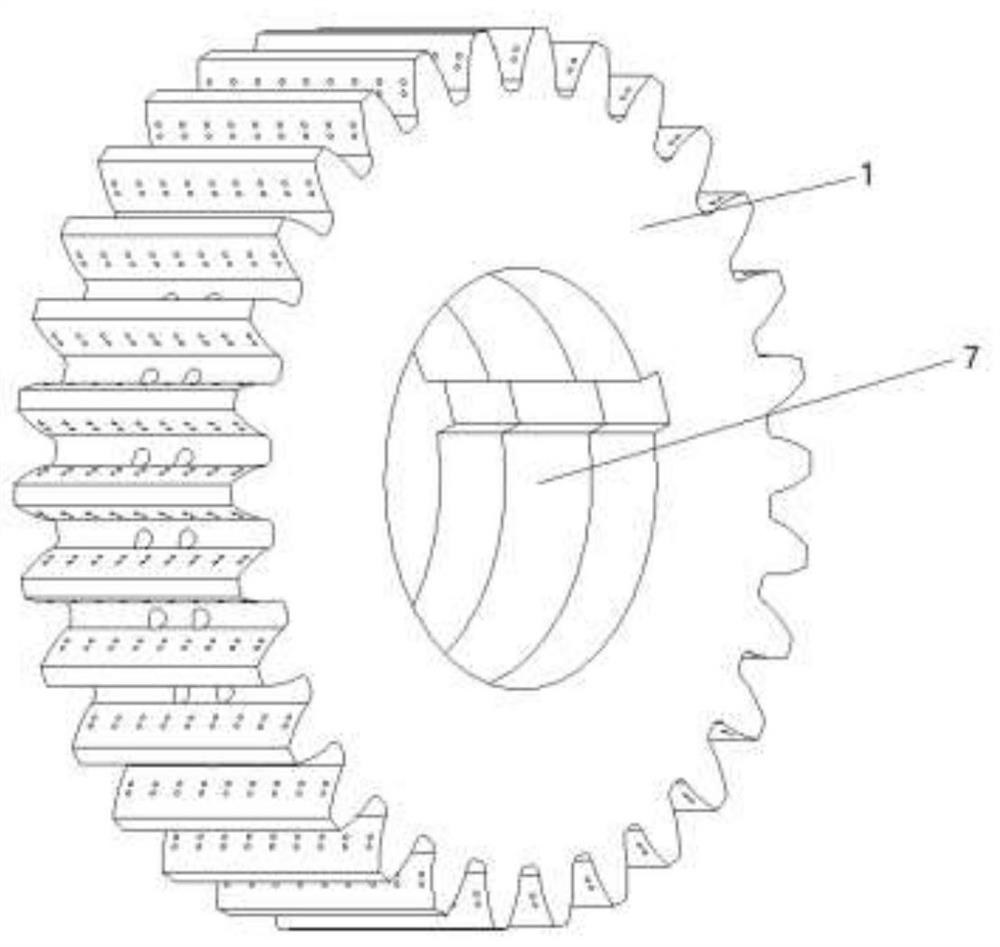

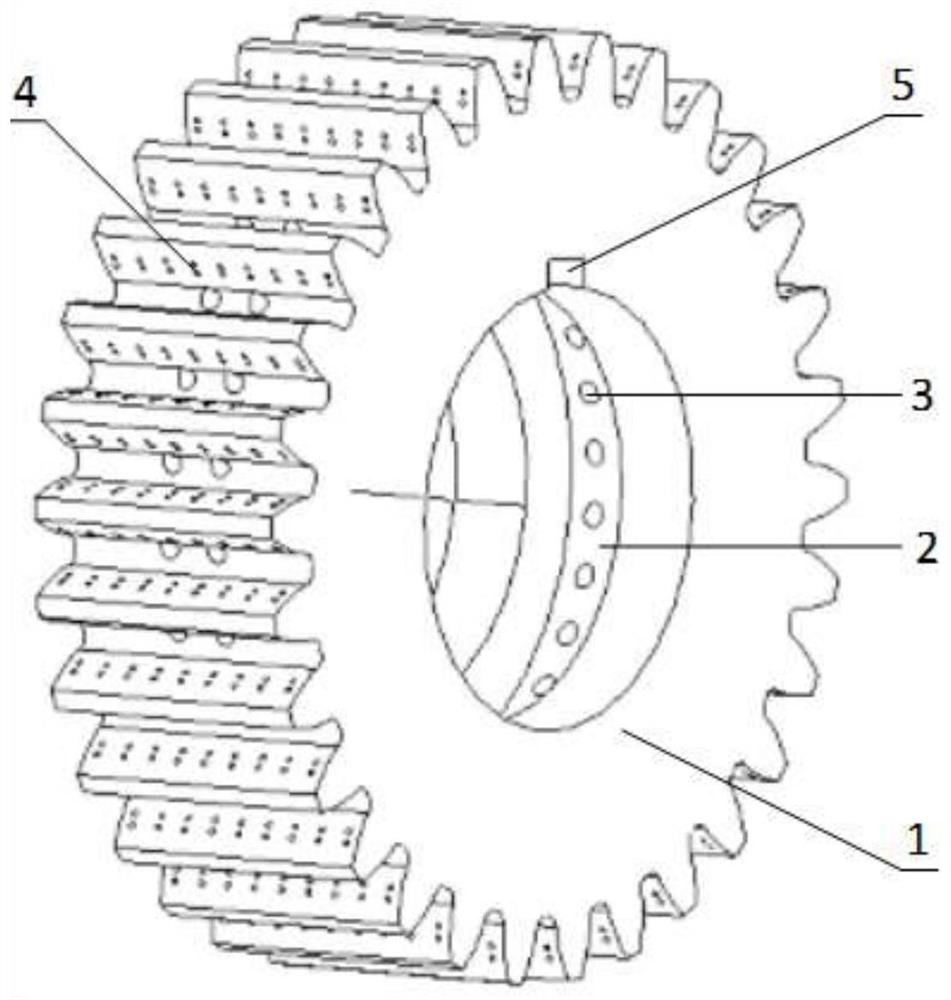

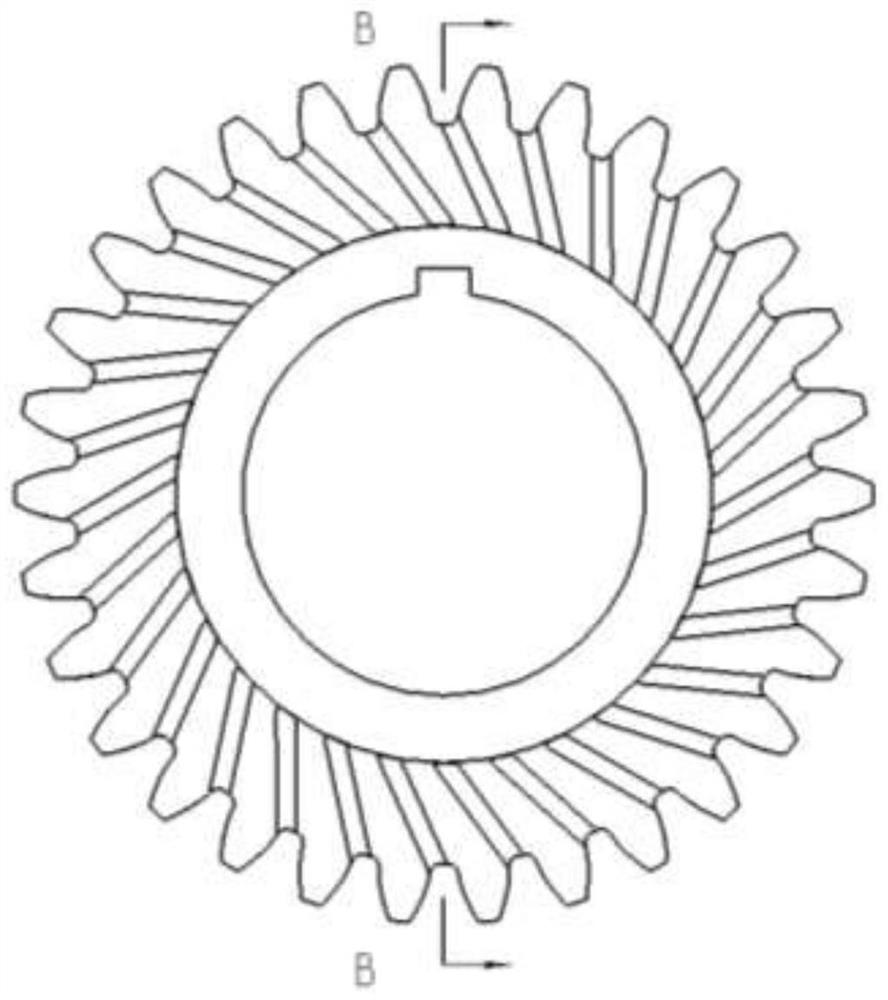

[0027] from figure 1 , figure 2 , image 3 , Figure 4 It can be seen that a self-lubricating gear with oil supply and oil return function of the present invention comprises a gear base 1, an oil storage groove 2, a porous oil storage body 7, an oil hole 3, a tooth surface micro-texture 4, and a keyway 5; The oil groove 2 is ring-shaped as a whole, set in the inner hole of the gear base 1, and extends to the inside of the gear base 1; the porous oil storage body 7 is ring-shaped as a whole, and is installed in the oil storage groove 2; the oil hole 3 is opened at one end On the top of the oil storage groove 2, the other end is set on the dedendum circle at the tooth groove of the gear base 1; the tooth surface micro-texture 4 is set on the front and rear tooth surfaces of each tooth of the gear base 1, The tooth surface micro-texture 4 is a cylindrical pit.

[0028] Wherein, the outer ring surface of the oil storage groove 2 is aligned with the inner hole of the gear, and...

Embodiment 2

[0031] Self-lubricating gear of the present invention: the material of porous oil storage body 7 is by one or more combinations in polyimide (PI), polyethyleneimine (PEI) etc.; Porous oil storage body 7 is based on cold press sintering Manufactured by technology, the pressing pressure is 200MPa-300MPa, the sintering temperature is 250°C-300°C, the holding time is 2h, and the oil storage rate of the sintered porous oil storage body is 45%-68%.

[0032] Polyimide (PI) and polyethyleneimine (PEI) are organic polymer materials, which have good stability and can still have good performance under high temperature conditions. The porous oil storage body 7 is made based on the cold press sintering process. After cold press sintering and vacuum oil immersion treatment, the porous oil storage body has a certain pore oil content and also has a certain mechanical strength. The pores inside the porous oil storage body 7 are randomly distributed, and the pores have a strong ability to lock ...

Embodiment 3

[0034] The self-lubricating gear of the present invention: the porous oil storage body 7 has a ring structure as a whole, and a keyway is arranged at the connection position of the flat key, which is matched and installed in the oil storage groove 2 .

[0035] The porous oil storage body 7 is installed in the oil storage groove 2, the two are in interference fit, and the keyway on it and the keyway on the gear base 1 form a whole, which is easy to install the flat key.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com