Tai Chi type combustion system

A combustion system, Tai Chi technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of low combustion thermal efficiency, insufficient air ejection force, and small ejection space of the burner head, so as to increase the ejection channel. , Improve the ejection force, improve the effect of combustion heat efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

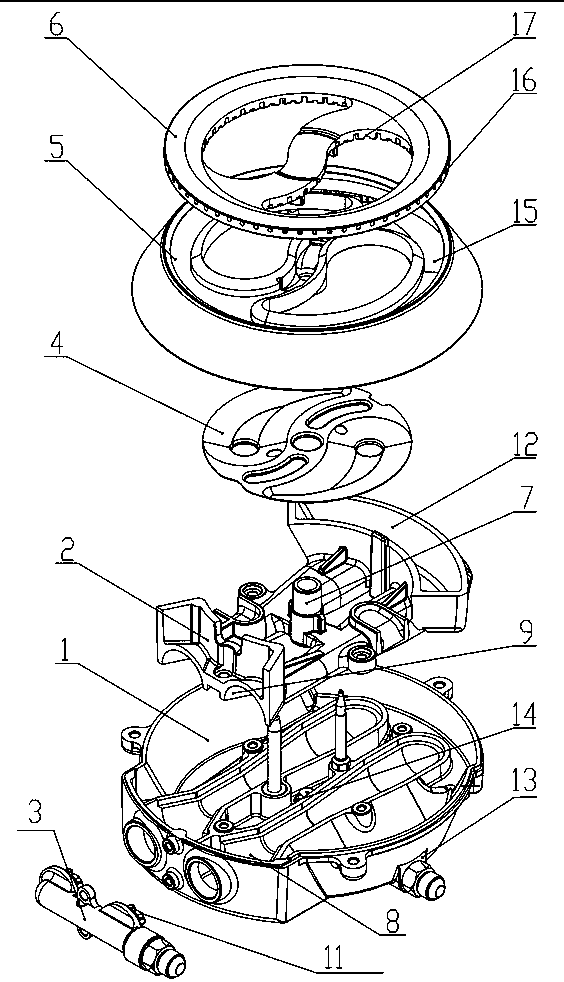

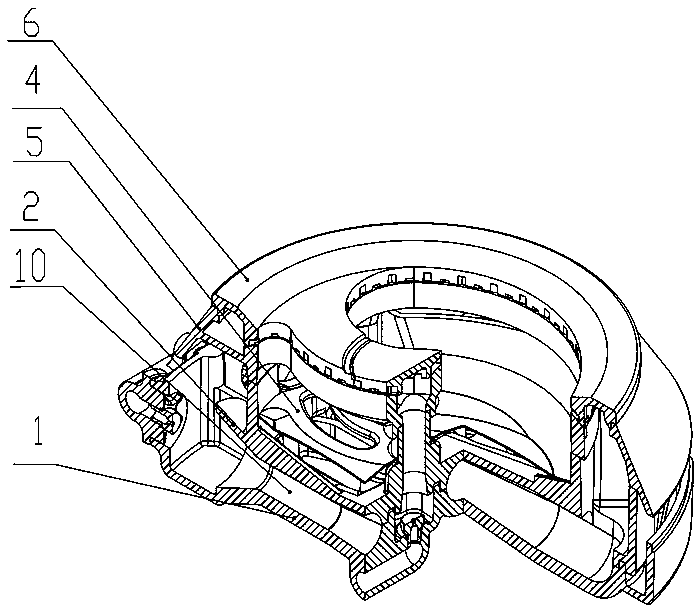

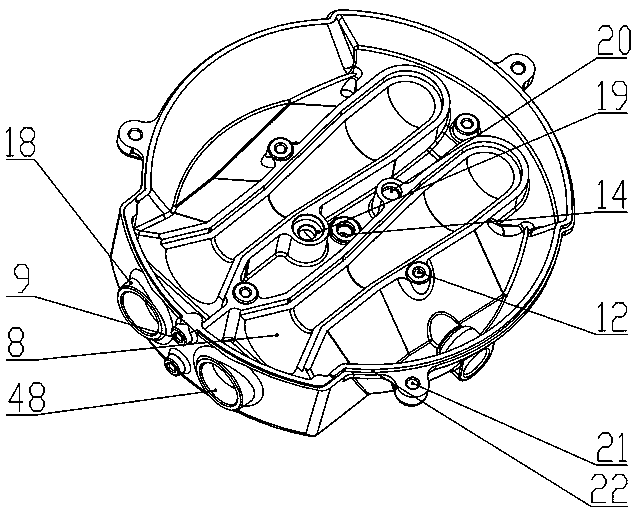

[0024] Example 1: Such as figure 1 and figure 2 As shown, the Tai Chi type combustion system includes the lower base of the furnace head 1, the upper base of the furnace head 2, the nozzle fixing base 3, the baffle plate 4, the fire cover base 5 and the fire cover 6. The lower base 1 of the furnace head is set in the most combustion system. The lower part is separately connected with the upper base 2 of the furnace head. The nozzle fixing base 3 is set on the side of the lower base 1 of the furnace head. In the middle of the upper base 2 of the furnace head is provided with a small fire ejection tube 7, a deflector 4 and 5 sets of fire cover bases. On the small fire ejection tube 7, the guide plate 4 is located between the upper base 2 of the furnace head and the flame cover base 5. The lower base 1 of the furnace is provided with the lower half 8 of the venturi ejection cavity, and the upper base of the furnace 2 There is the upper part 9 of the venturi ejection chamber, which...

Embodiment 2

[0025] Example 2: Such as Picture 11 As shown, in the Tai Chi type combustion system, the nozzle holder 3 is a pipe-shaped cylinder, one end of which is an air inlet 49, and two screw flanges 50 are provided in the middle to connect with the lower base of the burner 1, and the other One end is a gear-shaped positioning boss 51 communicating with the air inlet, and two nozzle installation ports 52 are provided in the center of the boss, and the rest are the same as in Embodiment 1.

Embodiment 3

[0026] Example 3: Such as Picture 12 As shown, in the Tai Chi type combustion system, the deflector 4 is a circular sheet formed by sheet metal stamping, the left and right sides are concave in the shape of Tai Chi, and the center of the Tai Chi on the left and right sides is provided with a deflector hole 53. Two ventilation slots 54, an ignition pin through hole 55, and a thermocouple through hole 34 are respectively provided in the middle, and the rest are the same as in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com