Motor type high precision automatic ultrasonic probe driving method

A technology of ultrasonic probe and driving method, which is applied in ultrasonic/sonic/infrasonic diagnosis, acoustic diagnosis, infrasonic diagnosis, etc., and can solve problems such as poor control accuracy of motor-type ultrasonic probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

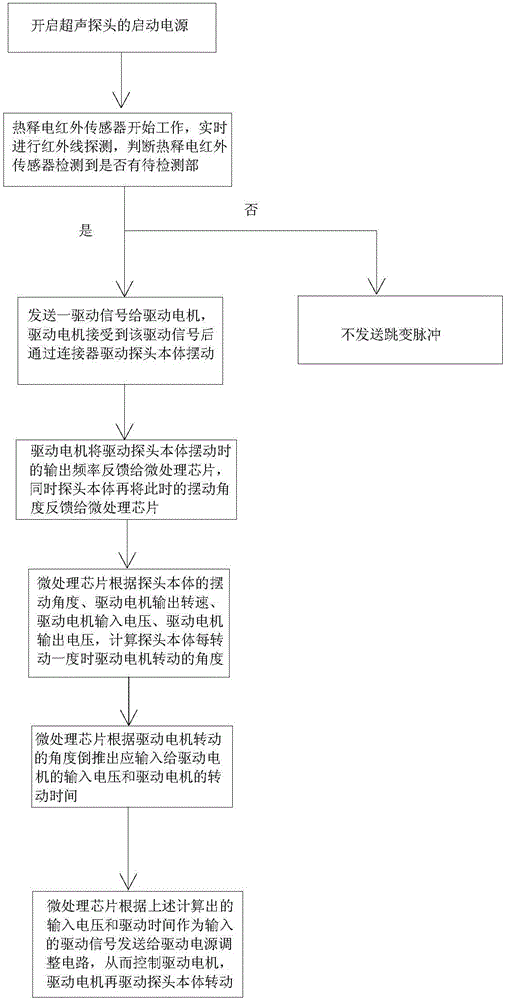

[0030] Embodiment: A motor-type high-precision automatic ultrasonic probe driving method

[0031] See attached figure 1 , build an ultrasonic probe driving platform in advance, the ultrasonic probe driving platform includes a probe body, a probe controller, a connector and a drive motor; the connector is connected to the drive motor and the probe body respectively, and the probe controller is connected to the drive motor , the driving motor is connected to the connector in transmission.

[0032] The probe controller includes a micro-processing chip, a storage module, an isolation circuit, an amplifying circuit, an analog-to-digital conversion circuit, a pyroelectric infrared sensor, a drive power supply, and a drive power adjustment circuit. Rated speed.

[0033] The probe driving method operates according to the following steps:

[0034] The first step is to turn on the starting power of the ultrasonic probe;

[0035] In the second step, the pyroelectric infrared sensor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com