A mixer for extracting shellfish toxins

A shellfish toxin and stirrer technology, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, chemical instruments and methods, etc., can solve the problems of prolonging the stirring time, reducing the stirring efficiency, and inconvenient discharge, so as to shorten the time , Improve the effect of stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

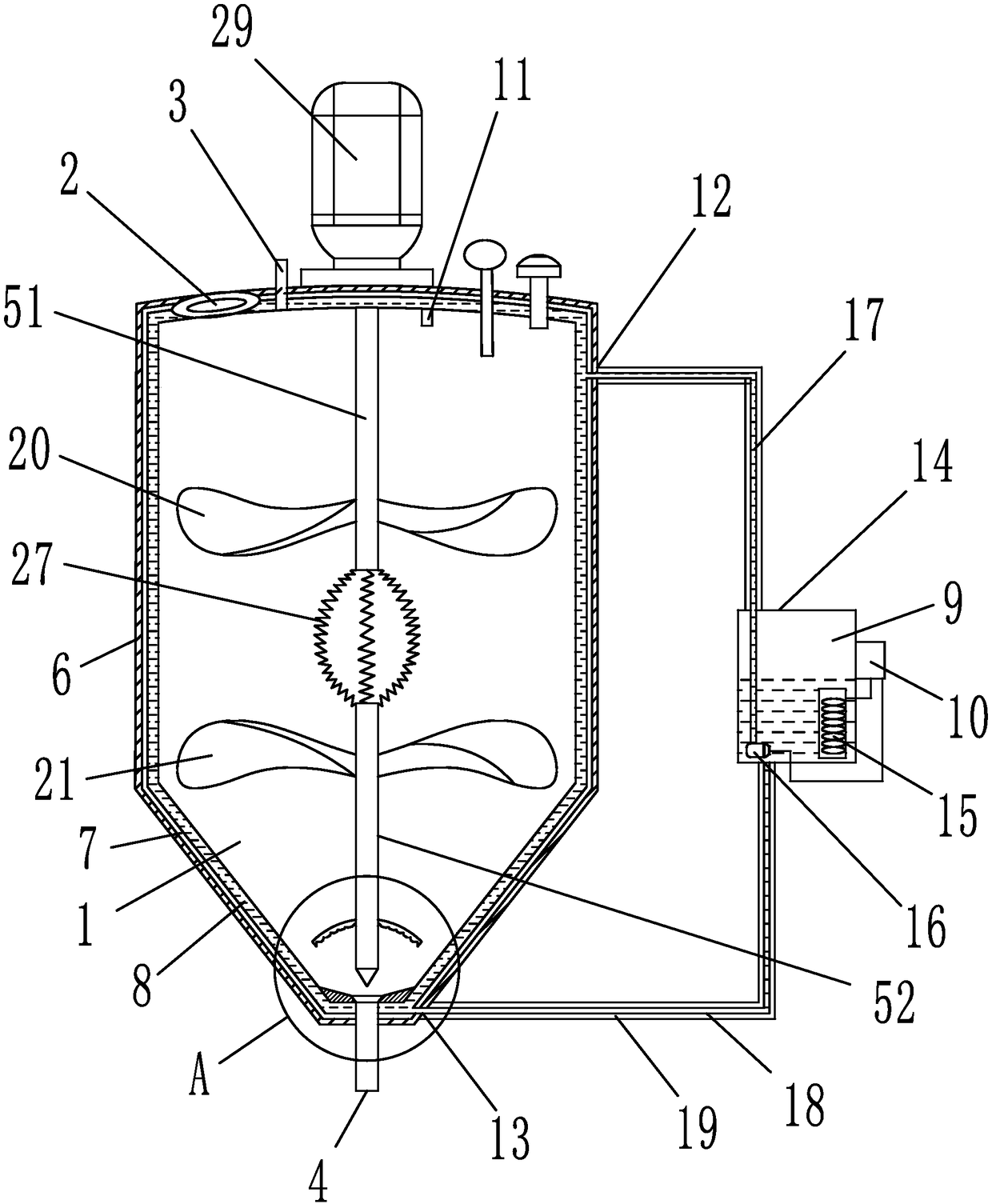

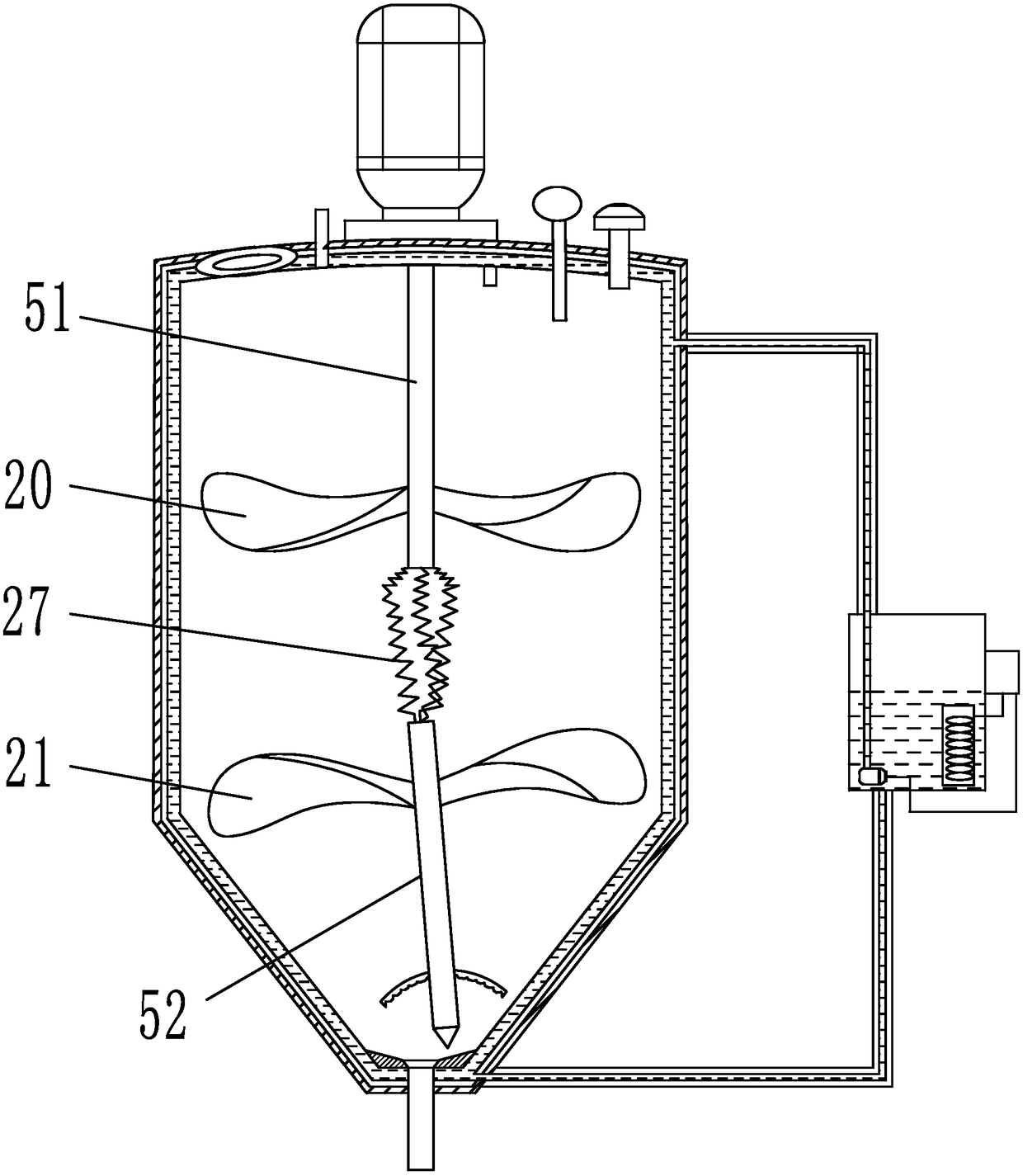

[0017] Embodiment 1: as figure 1 , 2 As shown, a stirrer for extracting shellfish toxins includes a stirring tank 1, and the stirring tank 1 is provided with an observation hole 2, a feeding hole 3, a discharging hole 4 and a stirring device.

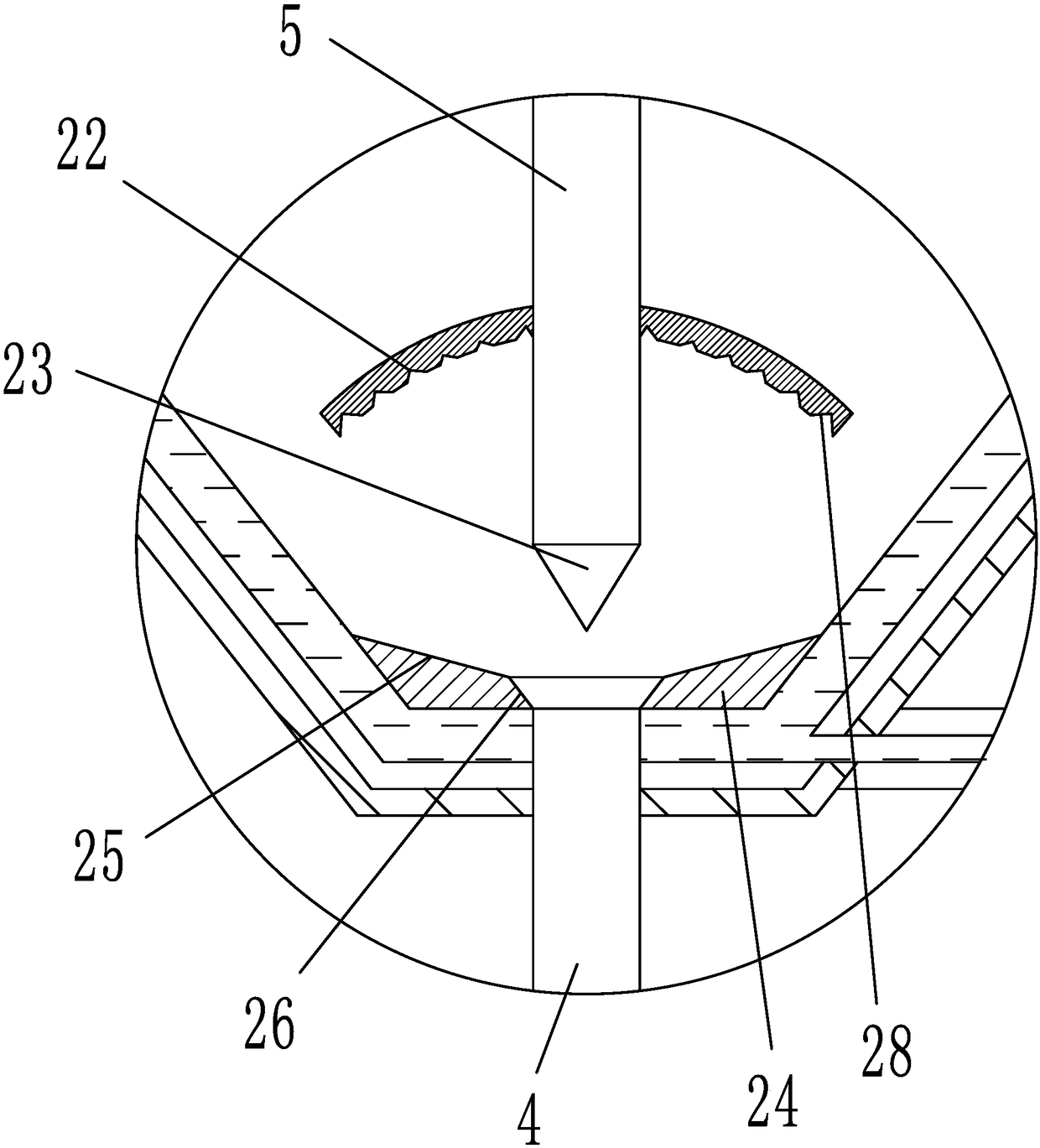

[0018] The stirring device comprises a motor 29 positioned at the top of the stirring tank, a drive shaft connected to the motor and positioned at the axis of the stirring tank, and a stirring impeller positioned on the drive shaft. The drive shaft comprises an upper half shaft 51 and a lower half shaft 52 arranged at intervals, several rigid springs 27 are arranged between the upper half shaft and the lower half shaft, the upper end of the rigid spring is fixed on the lower edge of the upper half shaft, and the lower end of the rigid spring Fixed on the upper edge of the lower half-shaft, the rigid spring is arc-shaped, and several rigid springs are distributed around the axis of the drive shaft. The stirring impeller includes an uptu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com