A doped modified nano ceo 2 Rod catalyst and its application

A catalyst and modification technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, catalytic treatment of combustible gases, etc., can solve the problem of easy reduction and deactivation of zinc-aluminum catalysts , easy sintering and oxidation, and achieve the effects of improving thermal stability and reverse water gas shift reaction performance, reducing the activation energy of oxygen ion diffusion, and improving high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

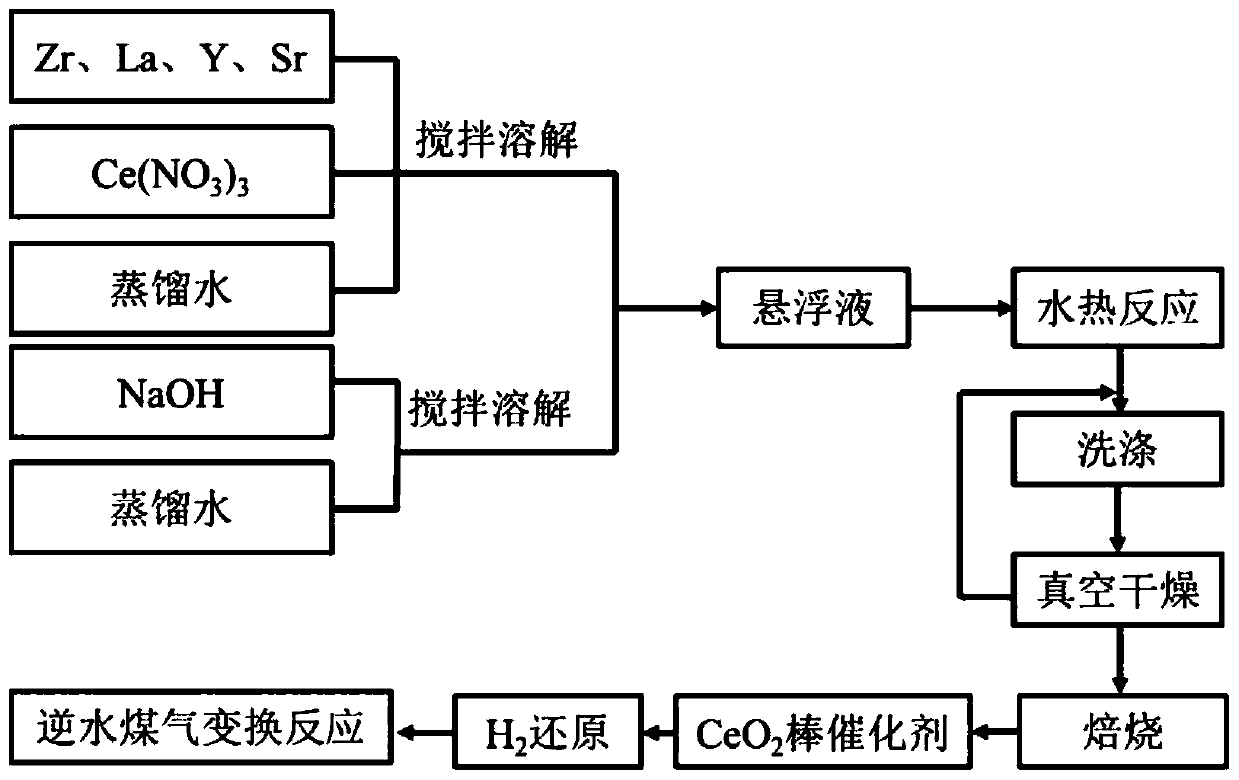

[0031] (1) Weigh 0.0172g Zr(NO 3 ) 4 ·5H 2 O and 1.736g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 70ml of distilled water and stirred for 30min to obtain the first solution;

[0032] (2) Accurately weigh 19.200g of NaOH and dissolve it in 10ml of distilled water, stir for 30min to obtain the second solution;

[0033] (3) Add the first solution dropwise to the second solution, and continue to stir for 30 minutes to obtain a suspension;

[0034] (4) Put the suspension into a 100ml PPL liner, put it into a stainless steel hydrothermal synthesis kettle, put the hydrothermal synthesis kettle into a 100°C oven and heat for 24h to obtain Zr-doped modified nano-CeO 2 Great;

[0035] (5) After the temperature of the hydrothermal kettle is naturally cooled, remove the supernatant, add deionized water to wash the precipitate twice, and centrifuge after ultrasonication for 20 minutes, then wash the precipitate with absolute ethanol, and centrifuge after ultrasonication for 20 minutes to...

Embodiment 2

[0040] (1) Weigh 0.0173g La(NO 3 ) 3 ·6H 2 O and 1.736g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 70ml of distilled water and stirred for 30min to obtain the first solution;

[0041] (2) Accurately weigh 19.200g of NaOH and dissolve it in 10ml of distilled water, stir for 30min to obtain the second solution;

[0042] (3) Add the first solution dropwise to the second solution, and continue to stir for 30 minutes to obtain a suspension;

[0043] (4) Put the suspension into a 100ml PPL liner, put it into a stainless steel hydrothermal synthesis kettle, put the hydrothermal synthesis kettle into a 100°C oven and heat for 24h to obtain Zr-doped modified nano-CeO 2 Great;

[0044] (5) After the temperature of the hydrothermal kettle is naturally cooled, remove the supernatant, add deionized water to wash the precipitate twice, and centrifuge after ultrasonication for 20 minutes, then wash the precipitate with absolute ethanol, and centrifuge after ultrasonication for 20 minutes to o...

Embodiment 3

[0049] (1) Weigh 1.736g Ce(NO 3 ) 3 ·6H 2 O was dissolved in 70ml of distilled water and stirred for 30min to obtain the first solution;

[0050] (2) Accurately weigh 19.200g of NaOH and dissolve it in 10ml of distilled water, stir for 30min to obtain the second solution;

[0051] (3) Add the first solution dropwise to the second solution, and continue to stir for 30 minutes to obtain a suspension;

[0052] (4) Put the suspension into a 100ml PPL liner, put it into a stainless steel hydrothermal synthesis kettle, put the hydrothermal synthesis kettle into a 100°C oven and heat for 24h to obtain Zr-doped modified nano-CeO 2 Great;

[0053] (5) After the temperature of the hydrothermal kettle is naturally cooled, remove the supernatant, add deionized water to wash the precipitate twice, and centrifuge after ultrasonication for 20 minutes, then wash the precipitate with absolute ethanol, and centrifuge after ultrasonication for 20 minutes to obtain a white precipitate;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com