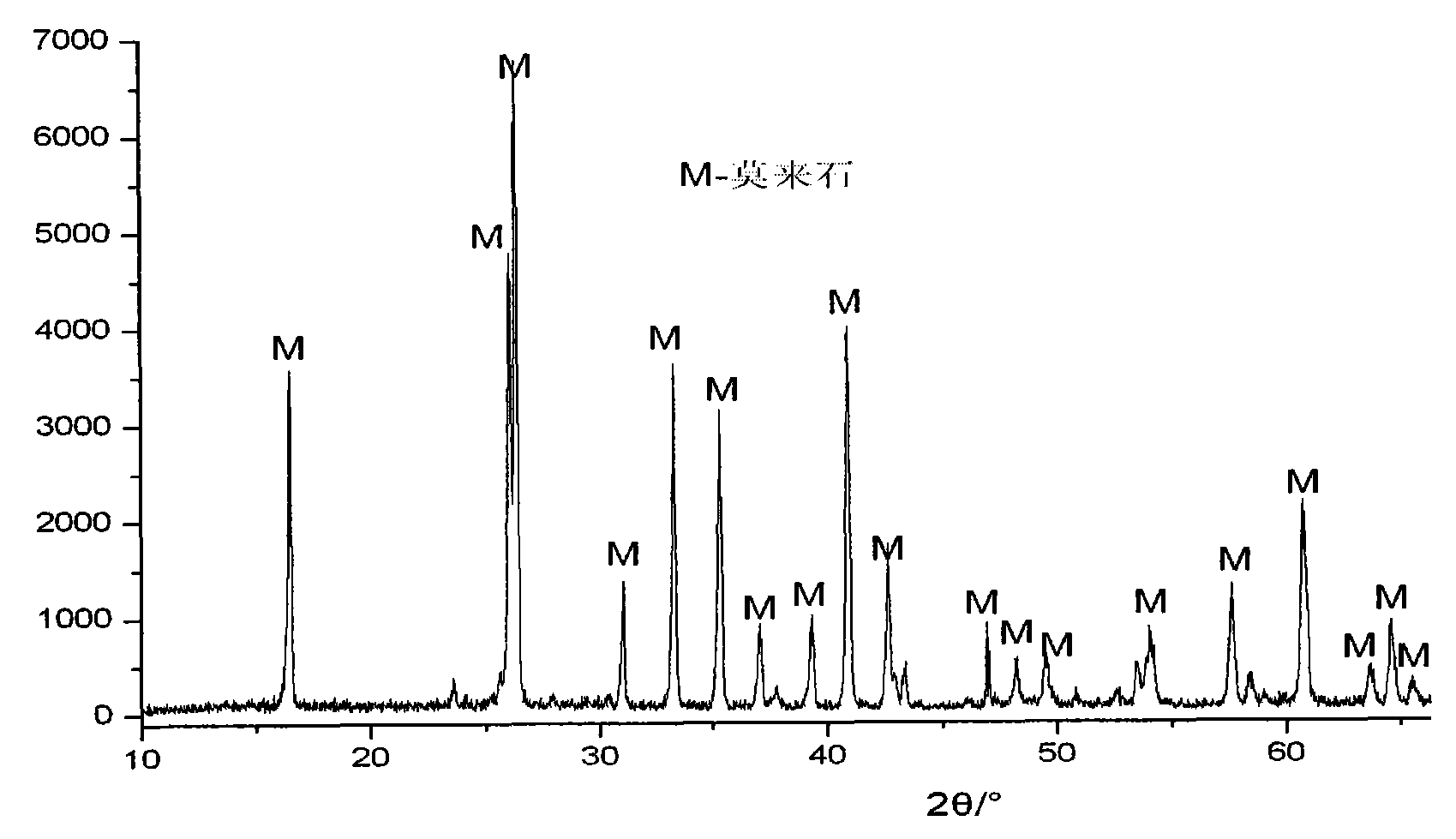

Method for preparing high-purity mullite monocrystal through kyanite concentrate at low temperature

A kyanite and mullite technology is applied in the field of low temperature preparation of high-purity mullite single crystal from kyanite concentrate, which can solve the problems of lack of reinforcement and toughness, low single crystal purity, crystal growth limitation, and the like. Achieving the effect of reduced waste discharge, high crystal purity, and reduced time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

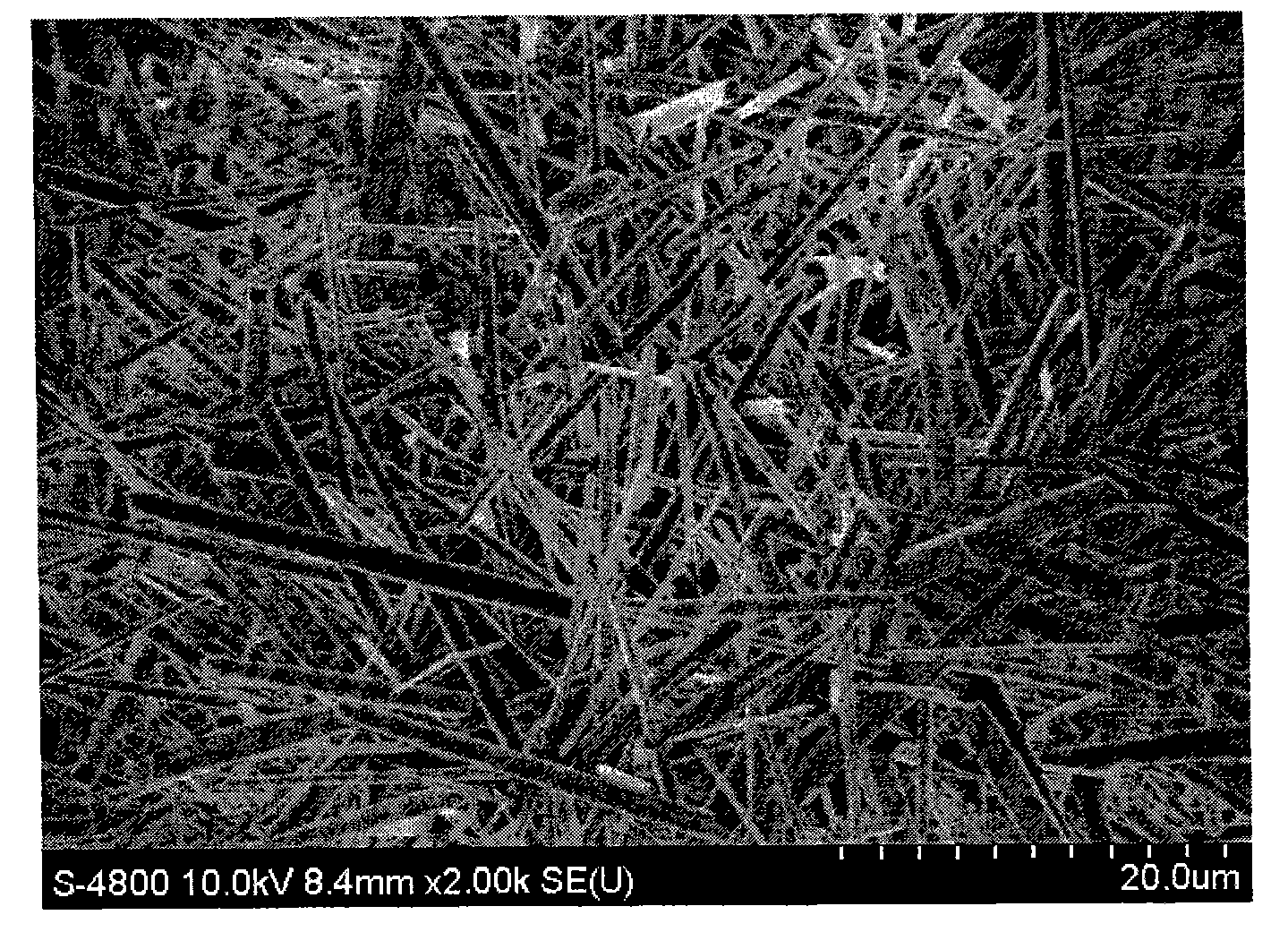

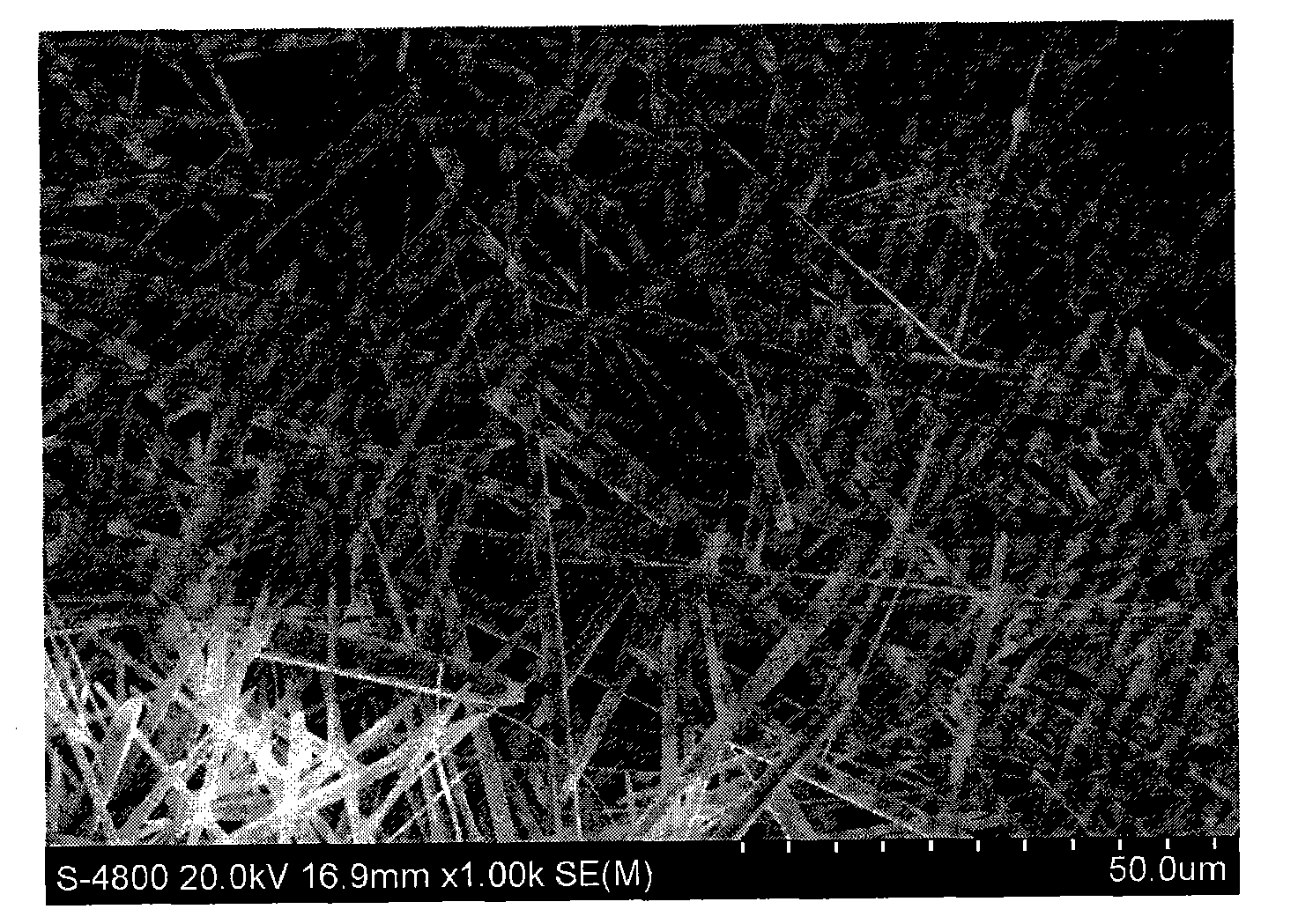

[0026] Select 10.00g of 37-44 micron kyanite concentrate with a purity of 96%, and accurately weigh 37-44 micron Al 2 o 3 3.20g, mixed evenly in a ball mill, put into a corundum crucible, weighed AlF 3 3.0g, put into the crucible independently, raise the temperature from room temperature to 900°C at a heating rate of 5°C / min, hold for 1 hour, then raise the temperature to 1100°C at a heating rate of 4°C / min, and hold for 3 hours. There is no kyanite remaining in the crucible, and the crystals are evenly distributed on the crucible wall, and the aspect ratio is 50-60.

Embodiment 2

[0028] Select 10.00g of 37-44 micron kyanite concentrate with a purity of 95%, and accurately weigh 37-44 micron Al 2 o 3 3.20g, mixed evenly in a ball mill, put into a corundum crucible, weighed 1.5gAlF 3, put it into the crucible independently, raise the temperature from room temperature to 900°C at a heating rate of 5°C / min, keep it for 0.5 hours, then raise the temperature to 1100°C at a heating rate of 4°C / min, and keep it for 2 hours. The yield of the crystal is 96%, the crystal is relatively uniform, and the aspect ratio is 40-50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com