Continuous stamping die for parent track material sheets of automobile seat slide rail

A technology for car seat slide rails and stamping dies, which is applied in the directions of forming tools, manufacturing tools, vehicle parts, etc., can solve the problems of affecting stamping accuracy, wear, and insufficient accuracy, and achieve the effect of avoiding side displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

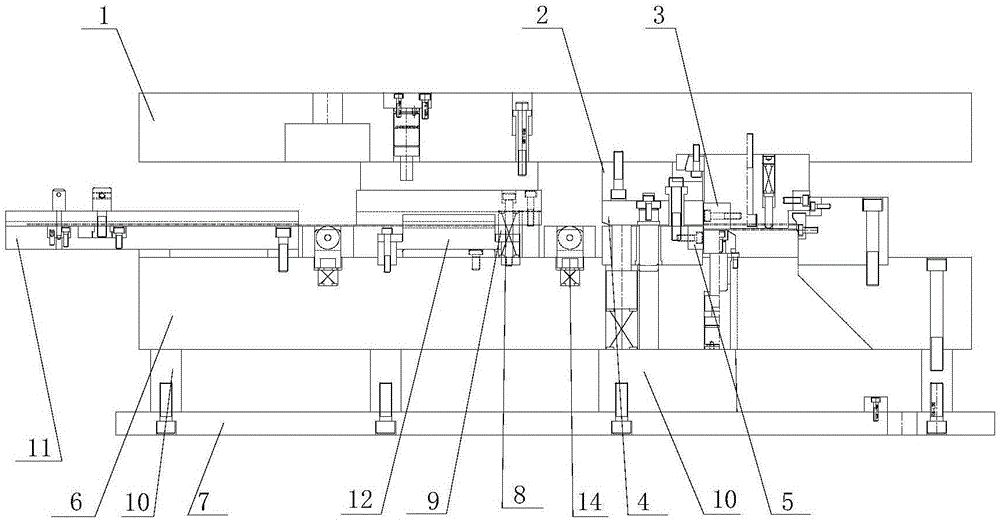

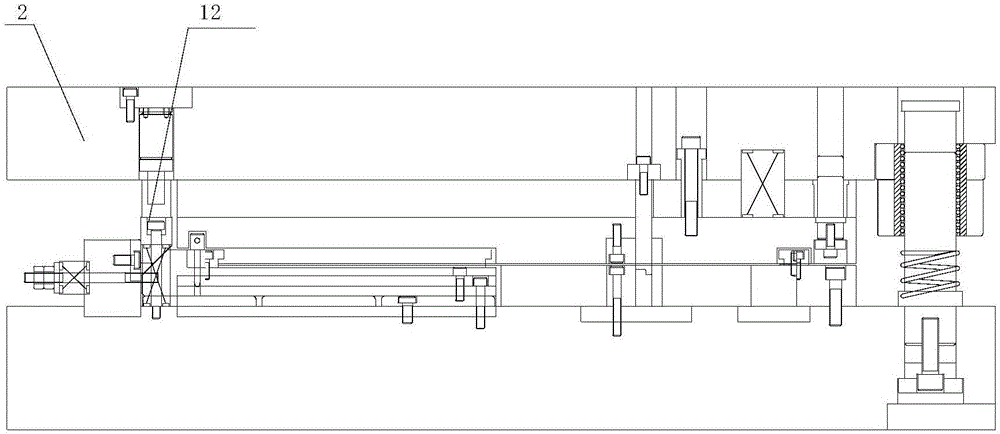

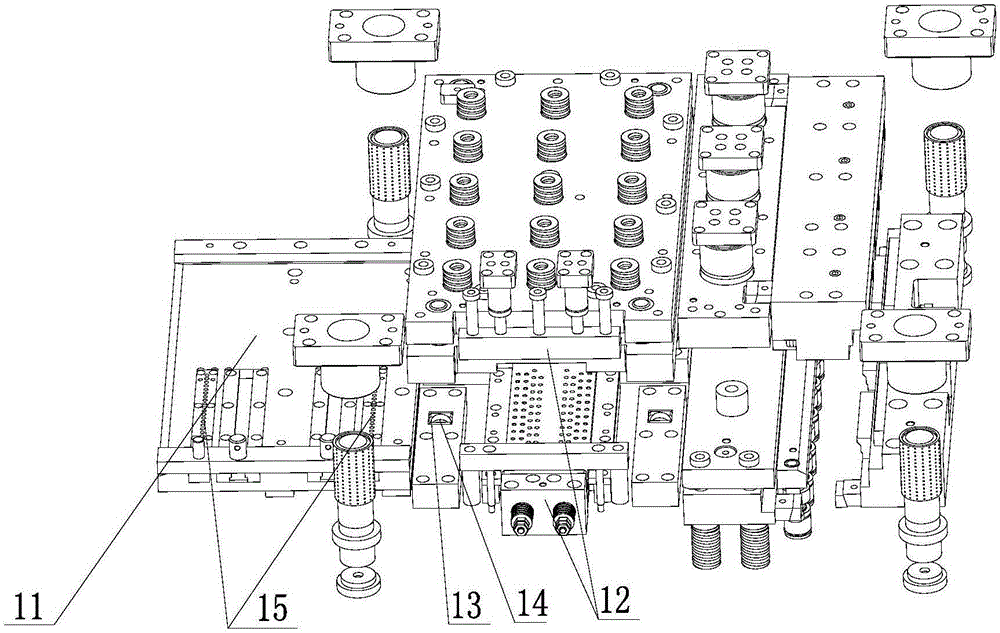

[0023] combine Figure 1 to Figure 9 , which describes a specific embodiment of the present invention in detail, but does not limit the claims of the present invention in any way.

[0024] Such as Figure 1 to Figure 3 As shown, a continuous stamping die for car seat slide rail mother rail material, including an upper template, a fixed plate, an upper knife-edge insert 3, a stripping plate 4, a lower knife-edge insert 5, and a lower template set from top to bottom 6. The lower positioning plate, the fixed plate 2 is set on the upper template, the upper knife edge insert 3 is set on the fixed plate 2, the unloading plate 4 is installed on the fixed plate 2 through the unloading screw 8, the unloading plate 4 and the fixed plate 2 is provided with a discharge spring 9, the lower blade insert 5 is arranged on the lower template 6, the lower template 6 is arranged on the lower positioning plate 7, and a lower foot 10 is arranged between the lower template 6 and the lower position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com