A straight nail forming processing equipment

A technology of forming processing and equipment, applied in the direction of mechanical equipment, nails, pins, etc., can solve the problems of reduced forming accuracy of straight nails, not particularly compact connection, reduced work efficiency, etc., to improve production efficiency and quality, and to divide the overall structure. Reasonable and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

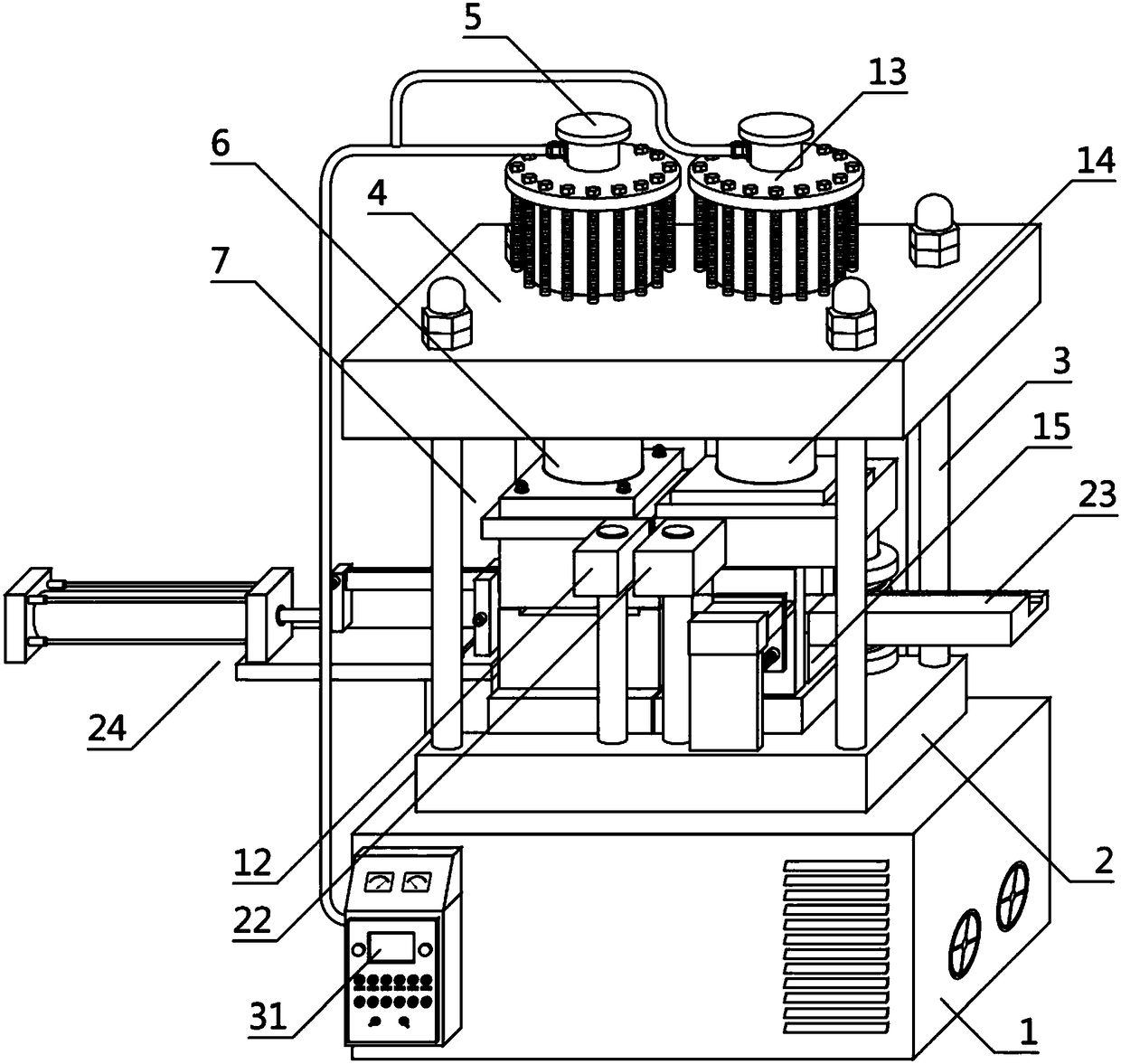

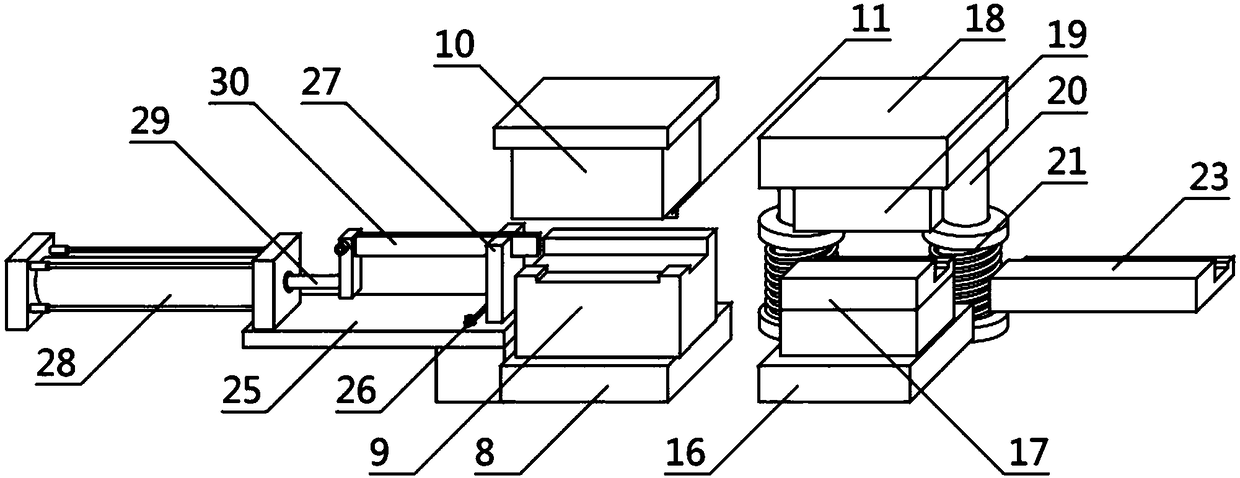

[0029] The specific embodiments of the present invention will be briefly described below in conjunction with the drawings.

[0030] Such as figure 1 , figure 2 Shown is a straight nail forming and processing equipment, which is characterized by: a main base 1, an operating table 2, a number of pillars 3, a top plate 4, a cutting drive device 5, a cutting lower pressing shaft 6, a cutting device 7, a cutting device The cutting and pressing positioning rail 12, the forming drive device 13, the forming lower pressing shaft 14, the forming device 15, the forming lower pressing positioning rail 22, the output station 23, the output device 24 and the control box 31 are composed of the operating table 2 located on the main base station 1, the operating platform 2 is fixedly connected to the main base 1, any of the pillars 3 are located on the upper part of the operating platform 2, the pillars 3 and the operating platform 2 are fixedly connected, and the top plate 4 is located on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com