Hinged pin shaft with cutting edge gap of shear capable of being adjusted

A hinge pin and adjustable technology, applied in metal processing and other directions, can solve problems such as rivet head wear, scissors scrapping, scissors cannot be in close contact, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

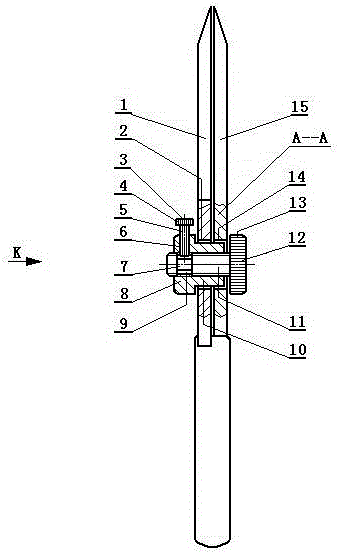

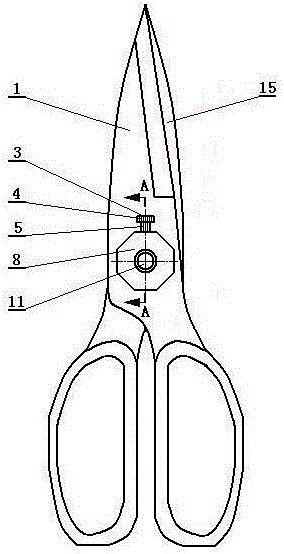

[0016] Embodiment: As shown in the accompanying drawings, a hinged pin shaft that can adjust the gap between the blades of scissors is composed of anti-loosening screw 5, pin shaft 10 and adjustment screw 11, and the first through hole of the left blade body 1 of the scissors assembled oppositely 2 and the second through hole 14 of the right cutter body 15 are provided with a bearing pin 10 for pinning the left cutter body 1 and the right cutter body 15, and the outer diameter of the bearing pin 10 is consistent with the first through hole 2 and the second through hole 14 Moving fit, the center line of the pin shaft 10 is provided with a threaded through hole 9, and the threaded through hole 9 is provided with an adjusting screw 11 for adjusting the gap between the scissors blades.

[0017] The left end of the adjusting screw 11 is provided with an annular groove 7, and the right end of the adjusting screw 11 is provided with a first round screw head 12 of integral structure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com