Newly increased cantilever beam frame steel armored anchor-pulling-method structure and process

A steel anchor and frame technology, which is applied in building construction, building maintenance, construction, etc., can solve the problems of poor shear resistance in the planting process, and achieve a mature and easy construction method, fast construction speed, and avoid complex stress conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

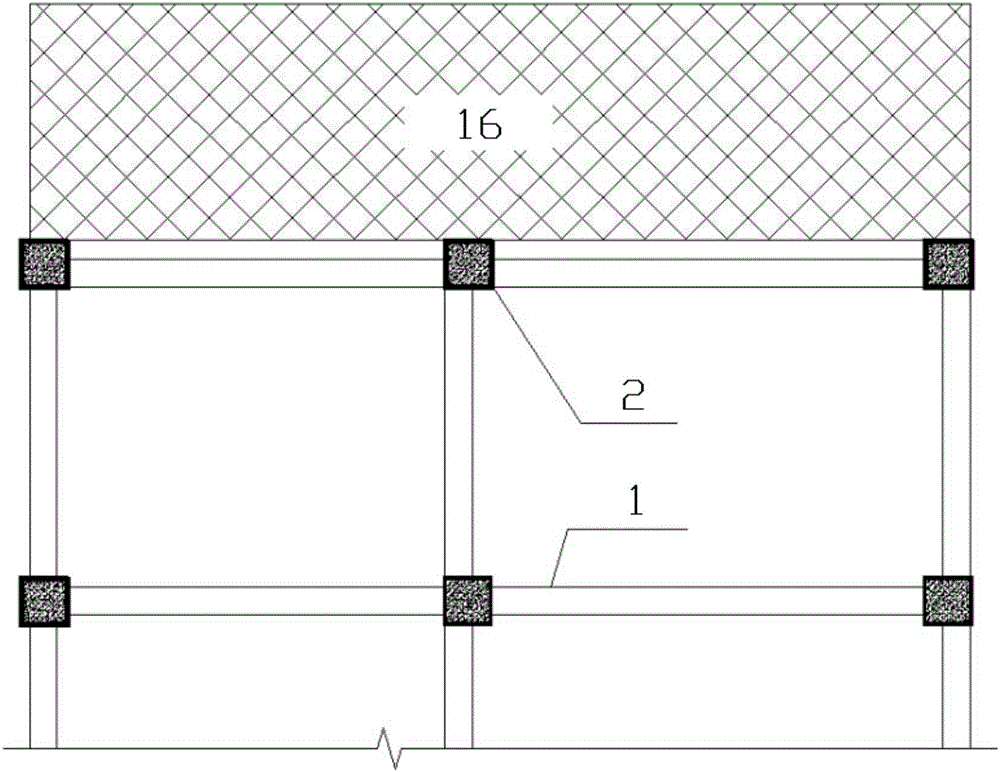

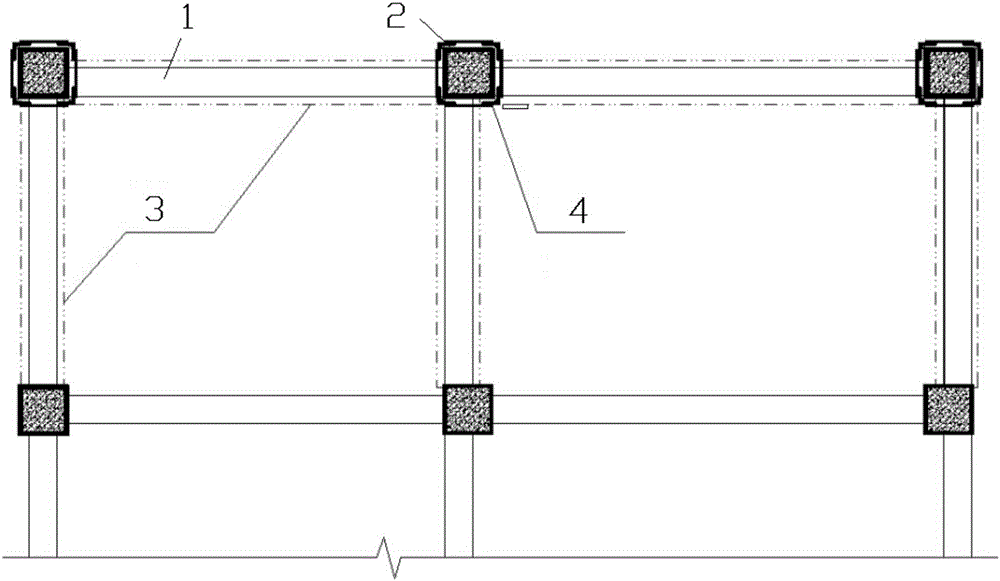

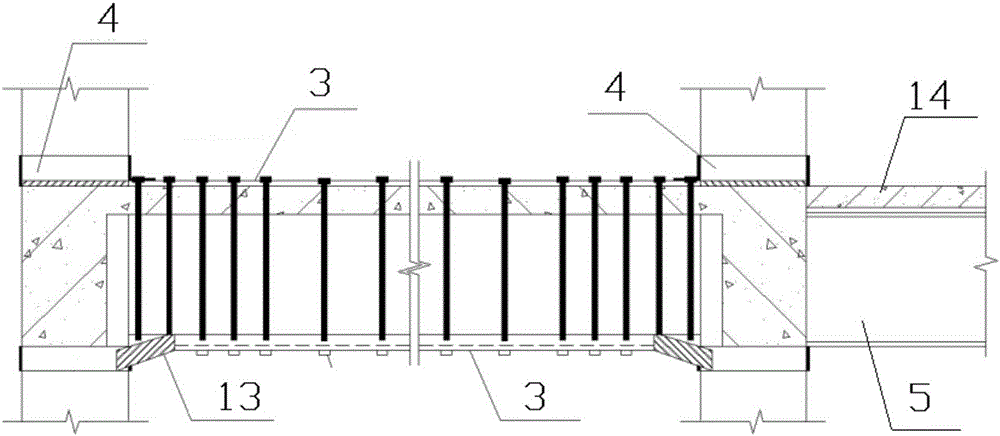

[0039] Such as Figure 1 to Figure 13 As shown, the present invention includes frame beam 1, frame column 2, cantilever beam 5, frame beam 1 and frame column 2 are both concrete structures, frame beam 1 is provided with beam outsourcing steel 3, and frame column 2 is provided with column outsourcing steel 4. The beam outsourcing steel 3 is fixedly connected with the column outsourcing steel 4, and the outer side of the column outsourcing steel 4 is fixedly connected with the steel anchor plate 6, and the steel anchor plate 6 is provided with holes for planting reinforcement, and high-strength bolts are used for planting reinforcement and tensioning The steel anchor plate 6 is fixed with the frame column 2 in the same way, the cantilever beam 5 is fixedly connected with the steel anchor plate 6, and the bottom of the cantilever beam 5 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com