Lightweight Potato Segmental Harvester Micro Potato Floating Crushing Device

A crushing device and potato technology, which is applied to digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of large environmental impact on potato planting, negative impact on germination and growth, and high processing costs, and achieve multi-functional improvement performance, avoiding work reliability, and improving negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

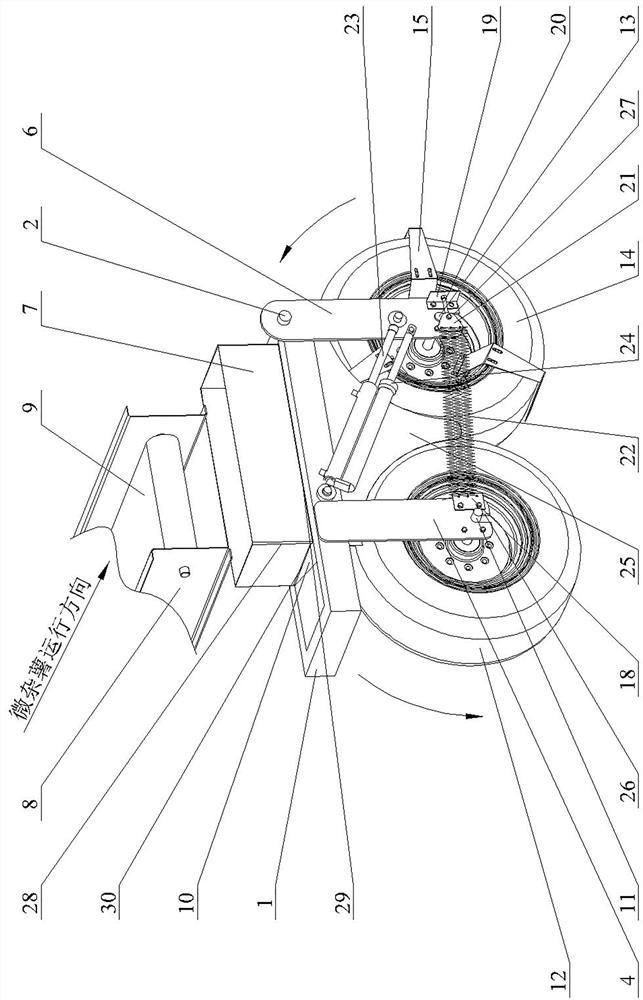

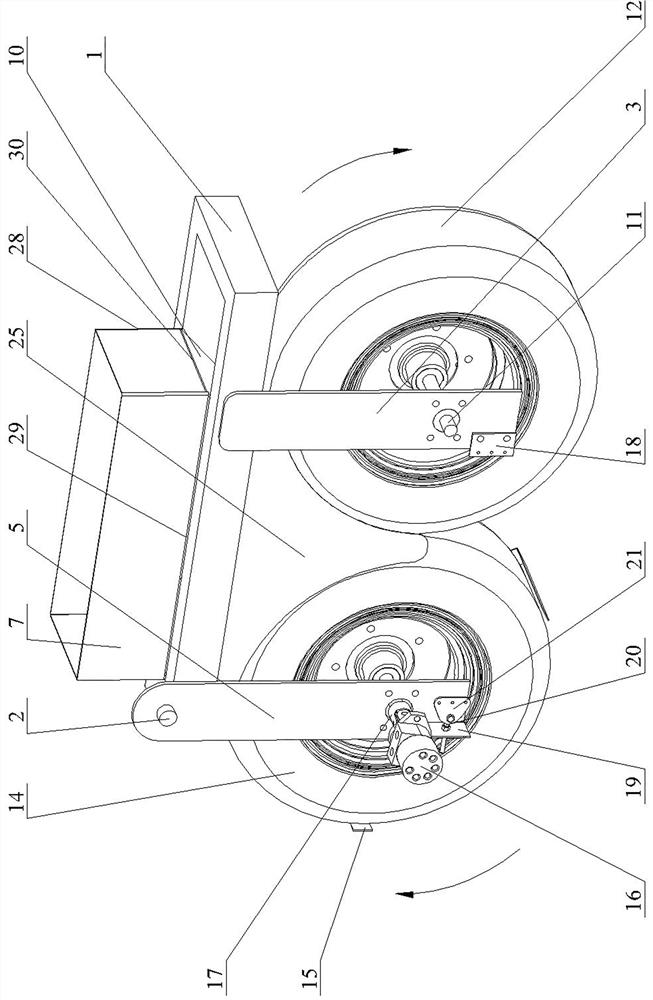

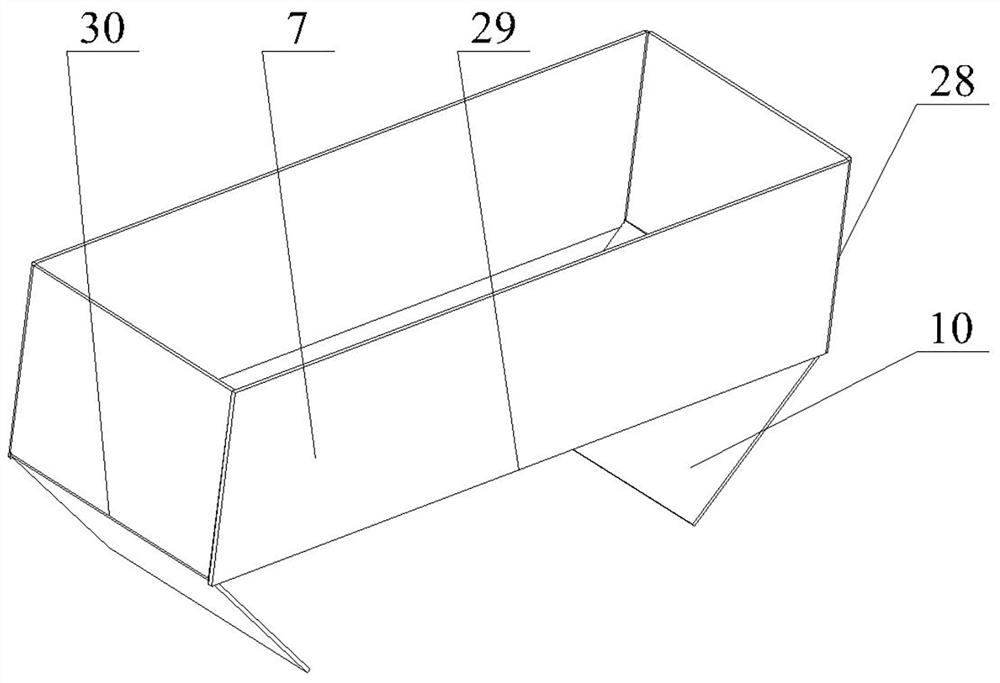

[0015] 1. Frame 2, supporting shaft 3, fixed arm Ⅰ 4, fixed arm Ⅱ 5, floating arm Ⅰ 6, floating arm Ⅱ 7, hopper 8, feeding frame 9, feeding belt 10, deflector 11, ground wheel shaft 12 , ground wheel 13, drive shaft 14, squeeze wheel 15, crushing knife 16, drive motor 17, coupling 18, fixed hanging plate 19, mounting plate 20, adjusting screw 21, swinging hanging plate 22, extension spring 23, hydraulic pressure Cylinder 24, linear displacement sensor 25, baffle plate 26, U-shaped slot I 27, U-shaped slot II 28, ridge line I 29, ridge line II 30, ridge line III.

[0016] exist Figure 1~Figure 4In the shown embodiment: the installation frame has a planar rectangular frame structure, and one end of the long frame of the horizontally arranged frame 1 is provided with a support shaft 2, and the axis of the support shaft 2 is perpendicular to the long frame of the frame 1, forming a rectangular plate One end of the fixed arm I3 is provided with a round hole, and one end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com