A kind of production method of gas lift and liquid discharge with self-buffered plunger

A production method and plunger technology, which are applied to parts of pumping devices for elastic fluids, earthwork drilling, liquid fuel engines, etc., can solve problems such as pollution, heavy workload, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

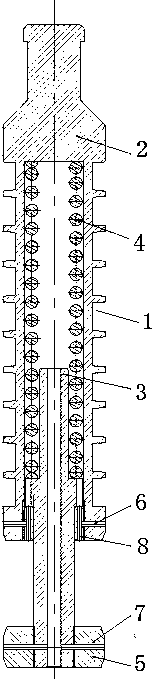

[0019] In order to solve the disadvantages of pollution, high cost, heavy workload, and poor drainage effect caused by the foam drainage process of traditional horizontal wells, this embodiment provides such problems as figure 1 A plunger with its own buffer is shown, including a plunger body 1 and a guide rod 3, the plunger body 1 is a hollow cavity, a buffer spring 4 is arranged in the hollow cavity, and one end of the guide rod 3 extends into the hollow cavity , the other end stretches out of the plunger body 1 and is covered with a guide head 5, the top of the plunger body 1 is a plunger fishing head 2; the guide rod 3 is covered with a retaining ring 8, which is located on the column The bottom end of the inner wall of the plug body 1, the retaining ring 8 and the plunger body 1 are connected by a spring pin-6.

[0020] The course of work of this plunger provided by the present embodiment is:

[0021] In the shut-in state, the plunger with its own buffer is lowered into ...

Embodiment 2

[0025] On the basis of Embodiment 1, in order to reduce the weight of the entire plunger and discharge the sand contained in the bottom hole fluid, the guide rod 3 has a hollow structure. In order to fix the position of the buffer spring 4 and prevent the buffer spring 4 from slipping, a step is provided at one end of the guide rod 3 extending into the hollow cavity of the plunger body 1 . Between described guide head 5 and guide rod 3, connect by spring cylindrical pin 2 7 or screw thread, spring cylindrical pin 2 7 plays the effect of fixing guide head 5. In order to realize that the plunger body 1 can go down under its own weight and finally stop running under the well shut-in state, the outer diameters of the plunger body 1 and the guide head 5 are both larger than the inner diameter of the tubing in the horizontal section of the horizontal well. In order to make the plunger body 1 fall smoothly, the guide head 5 is screwed to the bottom end of the guide rod 3, and the gui...

Embodiment 3

[0027] This embodiment provides a gas-lift liquid drainage production method with a self-buffered plunger. In the well shut-in state, the self-buffered plunger is lowered into a horizontal well (or a highly deviated well or a vertical well), and the The plunger with buffer moves downward as a whole and reaches the position of the reducing joint of the horizontal well. The guide head 5 of the plunger stops moving when encountering resistance, the plunger body 1 continues to descend under the action of inertia, the buffer spring 4 is compressed, and the plunger body 1 stops descending Then the well is opened, the plunger moves upward under the action of formation gas or injected gas, and at the same time lifts the bottom hole liquid to the well head, so far completes a cycle of gas lift liquid drainage and starts the next cycle. Safely realize gas recovery with plunger gas lift and liquid drainage with built-in buffer in horizontal gas wells. This device has been successfully pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com