Gas leakage safety valve

A technology of gas leakage and safety valve, which is applied in the directions of safety valve, control valve, balance valve, etc., can solve the problems of uncompact structure and large overall gas safety valve, and achieve the effect of stable flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

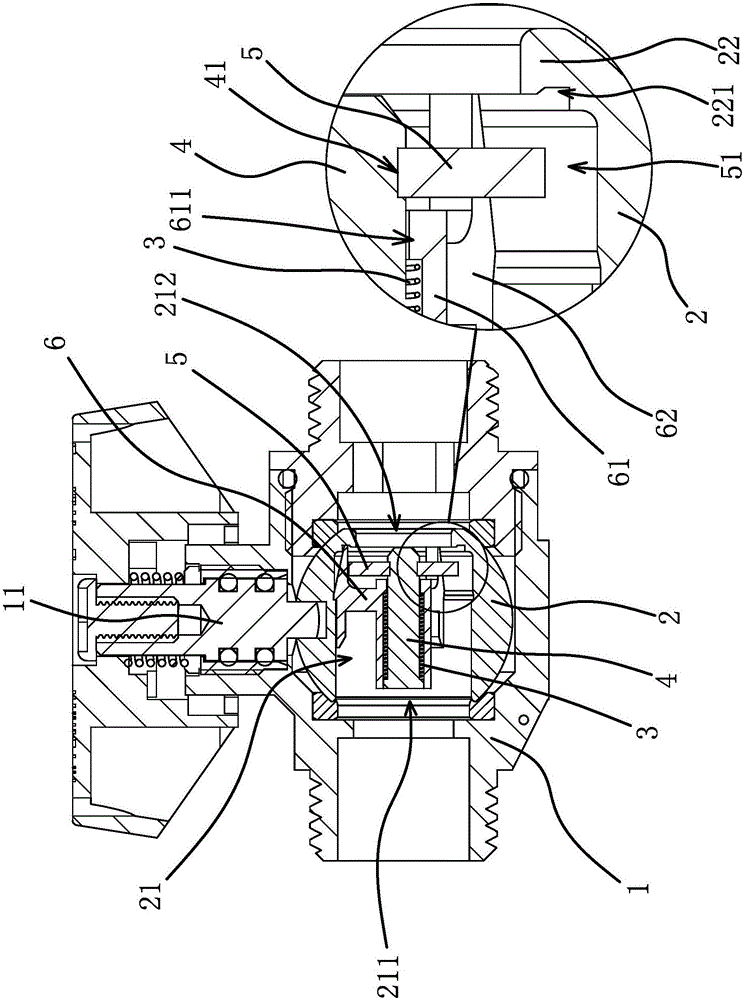

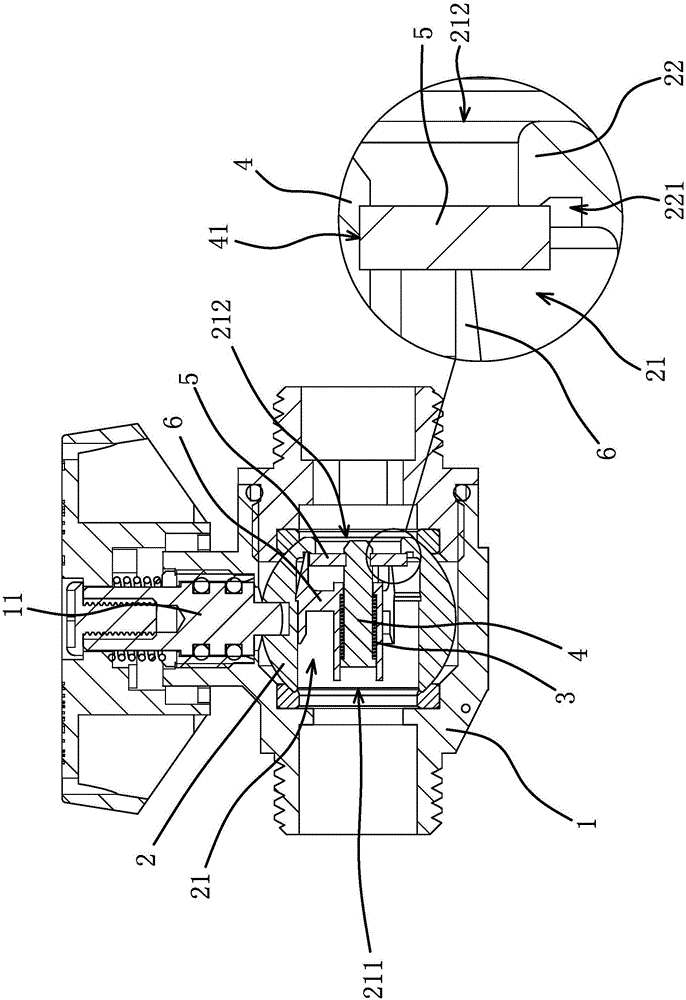

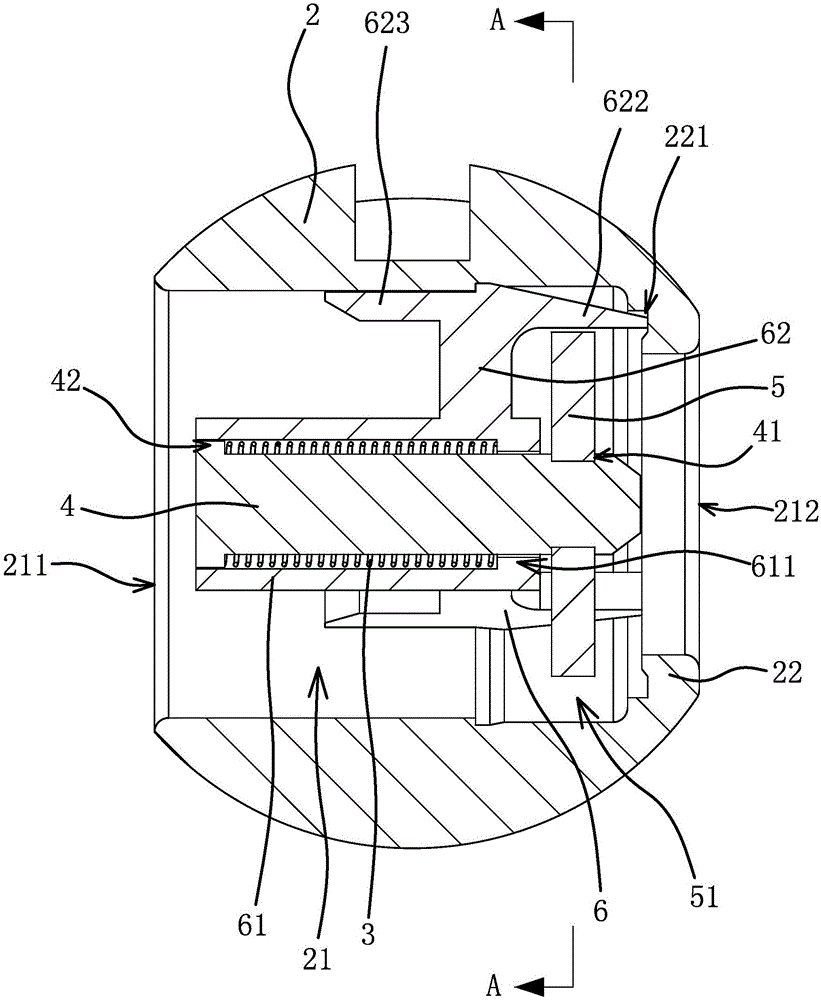

[0029] Such as Figure 1 to Figure 3As shown, the gas leakage safety valve includes a valve body 1, a valve ball 2 arranged in the valve body 1, and a valve stem 11 capable of driving the valve ball 2 to rotate. The valve ball 2 has a passage 21, and one end of the passage 21 is an air inlet. 211, the other end of the channel 21 is an air outlet 212; the safety valve also includes a spring 3, a check rod 4 and a circular sealing piece 5, and the check rod 4 has an annular groove 41, and the check rod 4 passes through The sealing sheet 5 and the sealing sheet 5 are stuck in the annular groove 41 .

[0030] Such as Figure 1 to Figure 4 As shown, the valve ball 2 is fixed with a non-return support 6, the non-return rod 4 is pierced on the non-return support 6 and the non-return rod 4 is arranged along the extension direction of the channel 21, the sealing sheet 5 is located in the valve ball 2 and Close to the gas outlet 212, the spring 3 is arranged between the non-return rod...

Embodiment 2

[0035] The structure and principle of this embodiment are basically the same as those of Embodiment 1, except that: there is a section of sealing section inside the valve ball 2, and the diameter of the sealing section gradually decreases from the end close to the air inlet 211 to the end close to the air outlet 212. The diameter of the sealing section is smaller than the diameter of the sealing piece 5. When the gas is not leaking, the sealing piece 5 is located in the valve ball 2 on the side of the sealing section close to the air inlet 211. When the gas leaks, the sealing piece 5 can move into the sealing section and be in contact with it. The inner wall of the sealing section seals against. When the gas is not leaking, the sealing sheet 5 is located outside the sealing section, so the gas can pass through the sealing section through the gas gap 51, and when the gas leaks, the sealing sheet 5 can move into the sealing section and seal against the inner wall of the sealing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com