A method for optimizing the clamping method of engine cylinder block and cylinder head

A technology of engine cylinder block and clamping, which is applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of large clamping deformation and other problems, and achieve the effect of improving flatness, ensuring performance, and ensuring air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention proposes a method for optimizing the clamping mode of the engine cylinder block and the cylinder head for the rapid milling of the cylinder block and the cylinder head of the automobile engine. By measuring and comparing the flatness of the top surface of the cylinder block and the bottom surface of the cylinder head, the optimum Excellent clamping method. Include the following steps:

[0029] The first step is to design a set of manual clamps according to the shape and structure of the gasoline engine cylinder block and cylinder head.

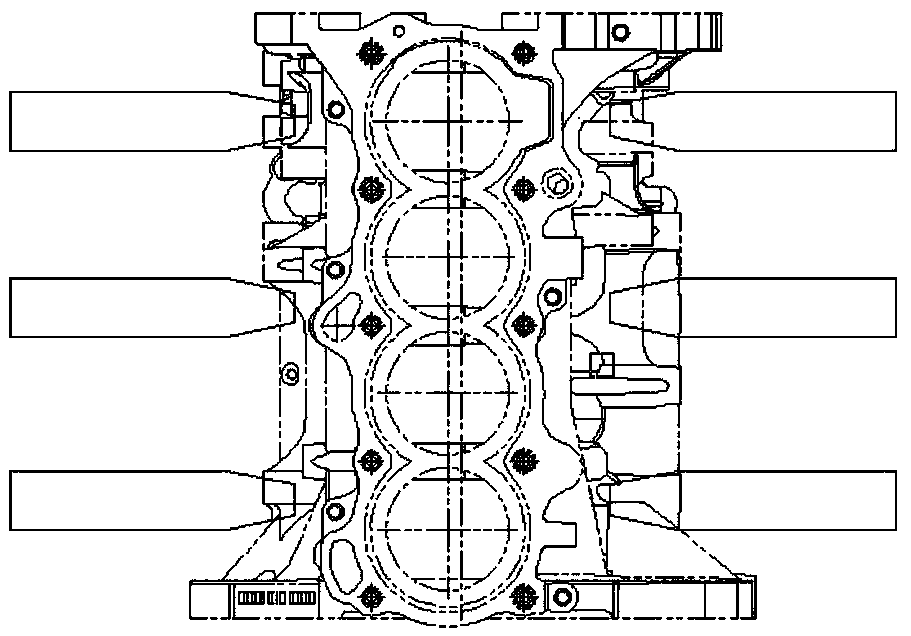

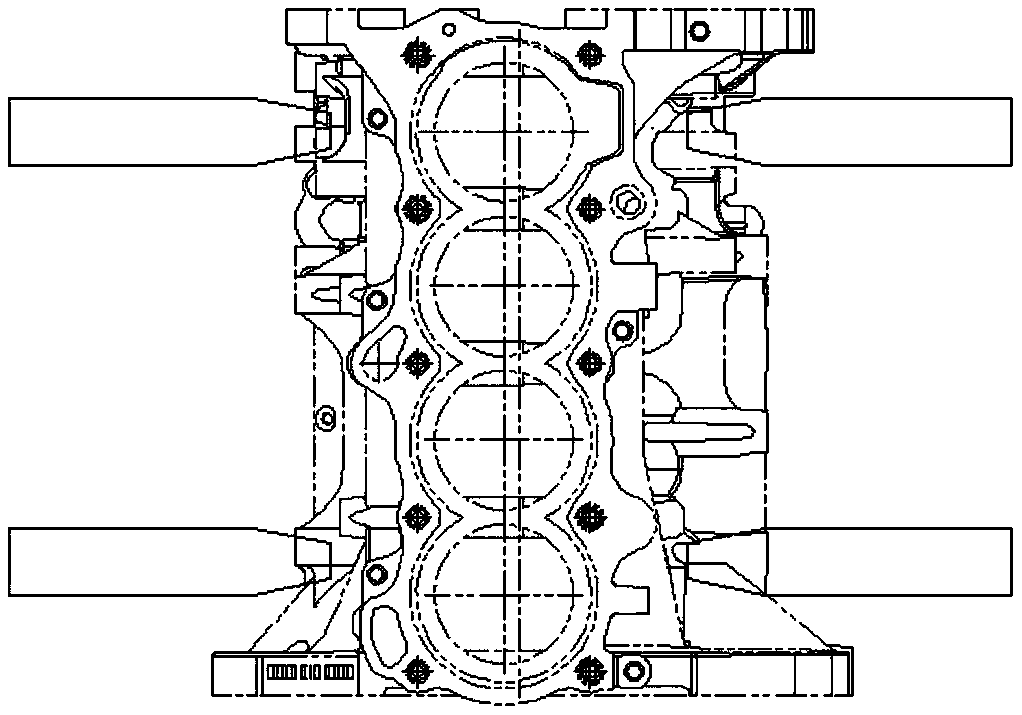

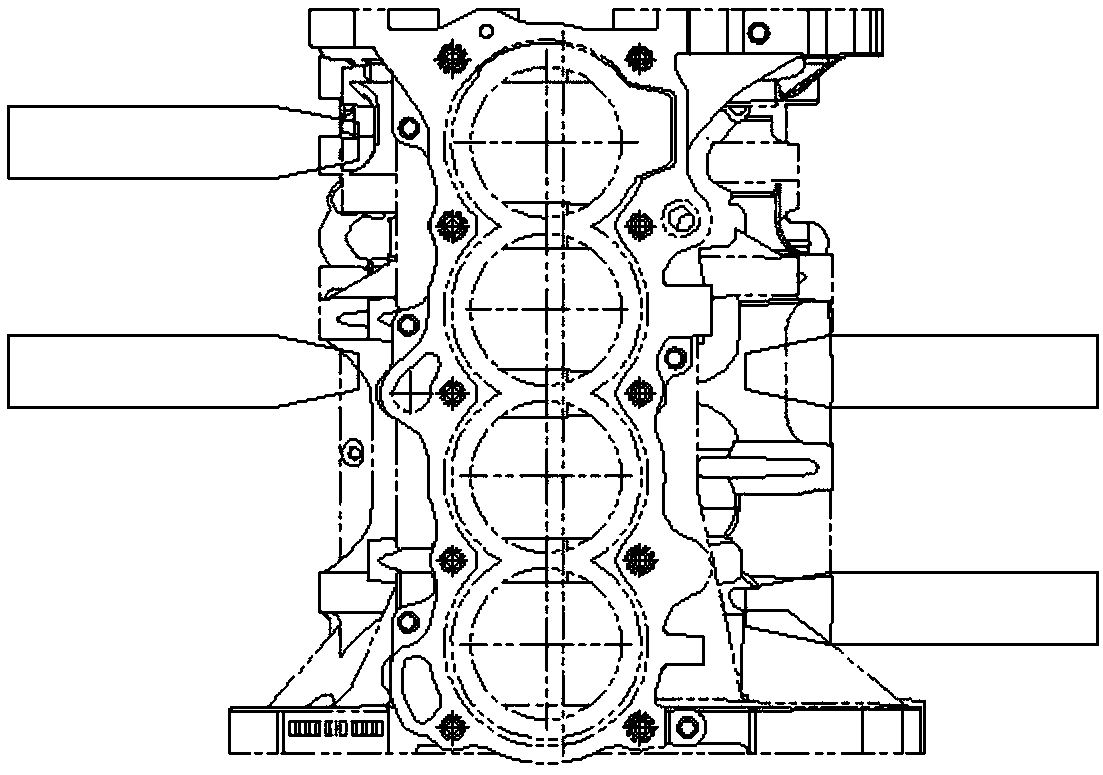

[0030] In the second step, the maximum number of clamping points on the cylinder is determined to be six, and four kinds of clamping point distribution schemes are designed, which are: a) six-point symmetrical and uniform distribution, b) four-point symmetrical and uniform distribution, c) Four-point non-uniform distribution, d) four-point non-uniform distribution, as shown in Figure 1(a), Figure 1(b), Figure 1(c)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com