Automatic measurement method for radial runout error of wheel pair tread

A technology of radial runout and automatic measurement, which is used in static/dynamic balance testing, measuring device, machine/structural component testing, etc. It can solve the measurement index requirements that cannot guarantee the detection accuracy of wheelset tread radial runout error, etc. problems, to achieve the effect of reducing the accumulation of errors, improving the coaxiality, and improving the measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

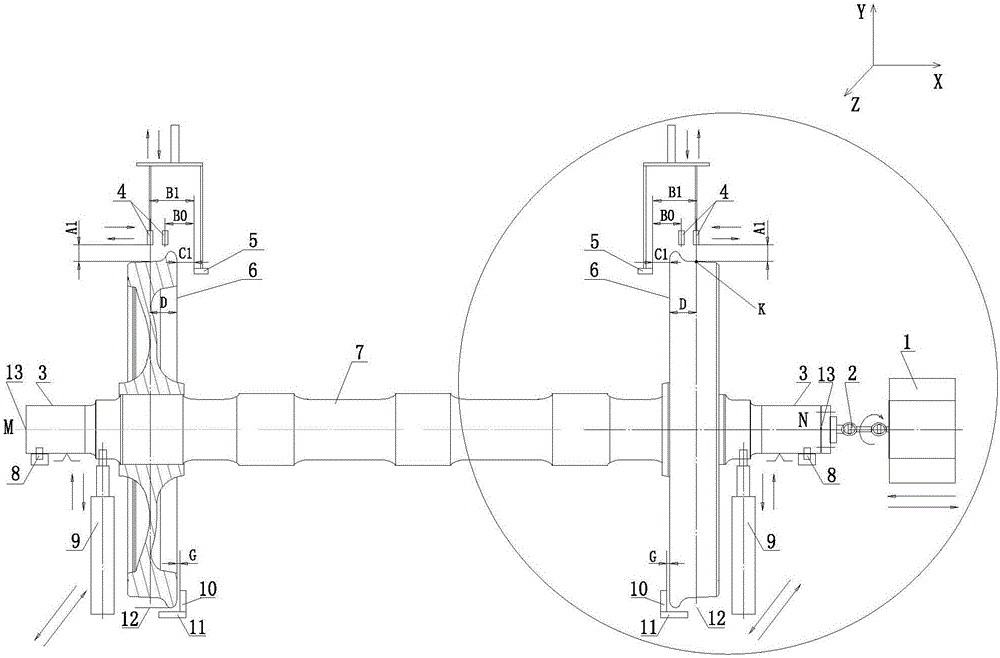

[0040] The present invention will be further described in detail below in conjunction with the drawings.

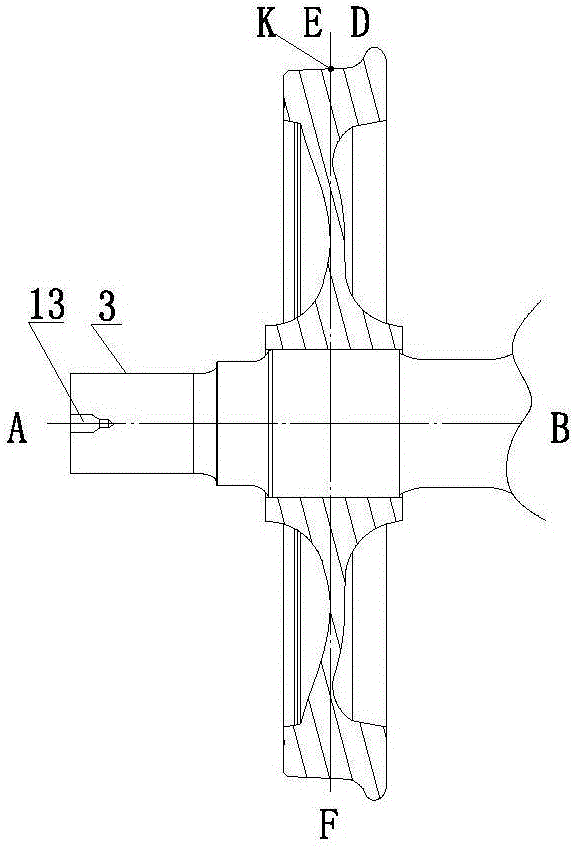

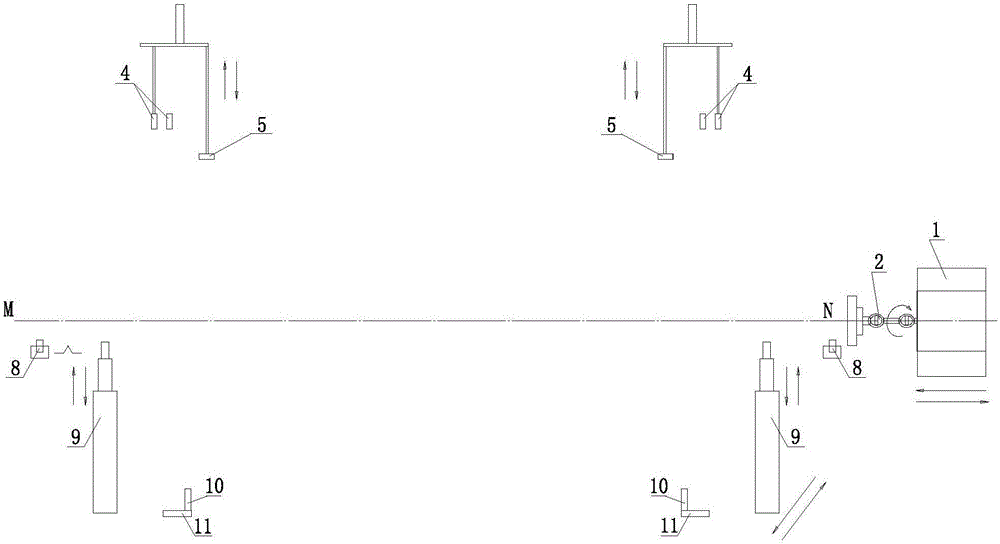

[0041] See attached figure 2 , The measuring device used to measure the radial runout error of the wheel-set tread includes a motor 1, a universal joint 2, a tread radial measuring sensor 4, a wheel inner side measuring sensor 5, a fixed V-shaped positioning support roller 8, an electric lifting automatic Translation device 9, fixed transverse positioning block 10 and fixed track 11; said motor 1 is connected to one end face of wheel set shaft diameter 3 through universal joint 2 and fasteners, and two sets of tread radial measurement sensors 4 are symmetrically arranged , Measure the inner sides 6 of the two wheels of the wheel set 7. Two sets of measuring sensors 5 on the inner side of the wheel are arranged symmetrically to measure the rolling circles of the two wheel treads of the wheel set 7. Two fixed V-shaped positioning support rollers 7 Symmetrical arrangement to s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap