A detection device and detection method for non-condensable gas in steam

A detection method, a gas detection technology, applied in the field of coal chemical industry, can solve the problems of long measurement time, damage to the instrument, failure to measure, etc., and achieve the effect of ingenious method, guaranteed output, and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

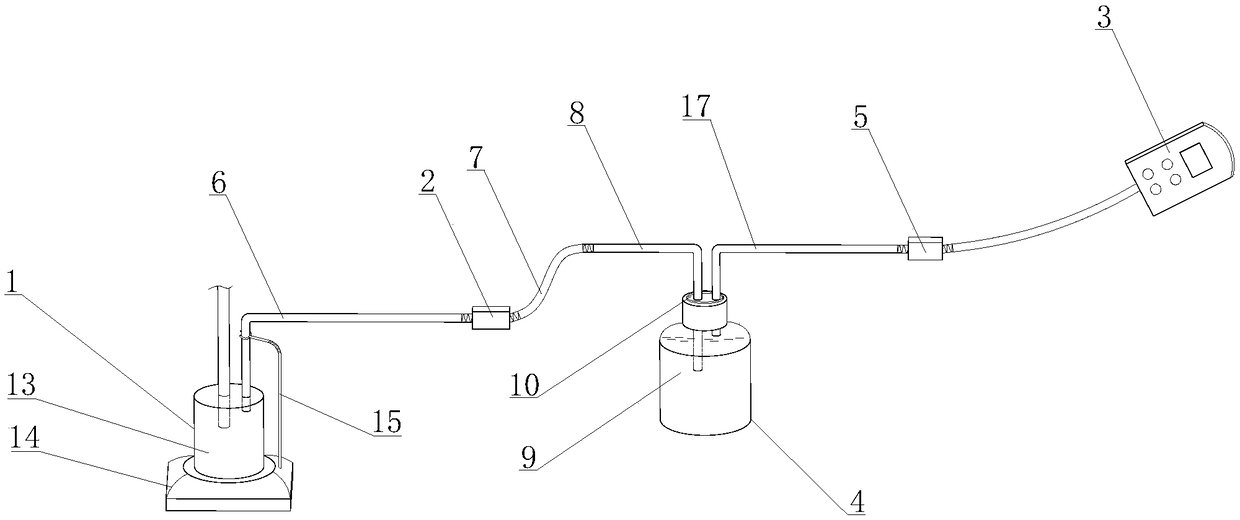

[0035] Embodiment 1 of the present invention: a detection device for non-condensable gas in steam, including a tank device 1, a flow meter 2, b flow meter 5, a gas detection device 3 and a gas washing bottle device 4, the tank device 1 The first right-angle pipe 6 is connected to the a flowmeter 2, the a flowmeter 2 is connected to the gas washing bottle device 4 through the hose 7 and the long conduit 8, and the gas washing bottle device 4 is connected to the b flowmeter 5 through the short conduit 17 , b The flow meter 5 is connected to the gas detection device 3 . The gas washing bottle device 4 includes a glass bottle body 9 and a rubber stopper 10 , and the rubber stopper 10 is covered on the mouth of the glass bottle body 9 . The tank device 1 comprises a tank body 13, a tank body holder 14, a pipe body holder 15 and a base 16, the tank body 13 is arranged on the base 16 by the tank body holder 14, the pipe body holder 15 and the tank body holder 14 Connection, the bott...

Embodiment 2

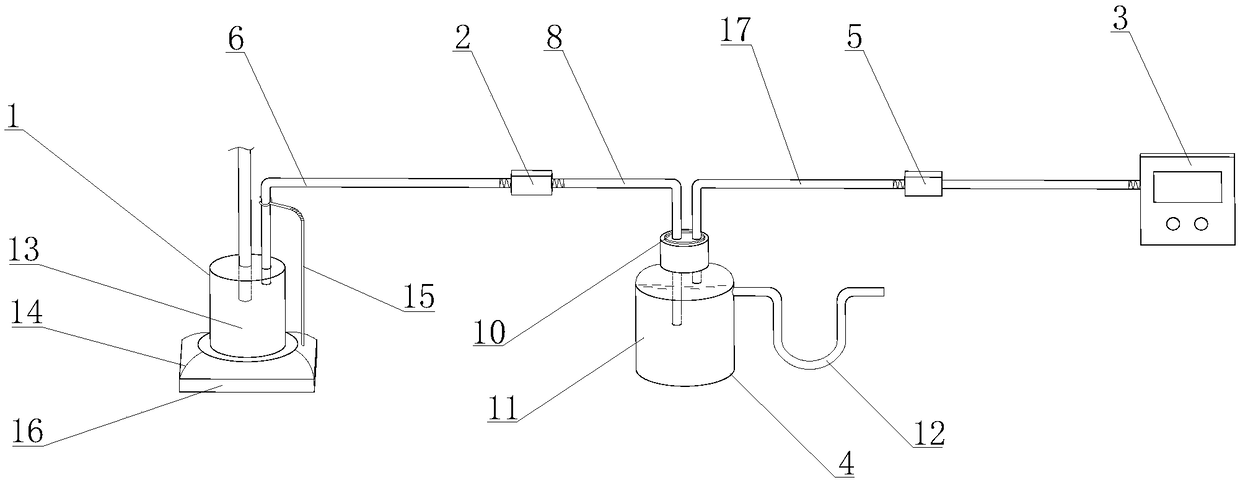

[0036] Embodiment 2 of the present invention: a detection device for non-condensable gas in steam, including a tank device 1, a flow meter 2, b flow meter 5, a gas detection device 3 and a gas washing bottle device 4, the tank device 1 The a flow meter 2 is connected to the a flow meter 2 through the first right-angle pipe 6, the a flow meter 2 is connected to the gas washing bottle device 4 through a long conduit 8, the gas washing bottle device 4 is connected to the b flow meter 5 through a short conduit 17, and the b flow meter 5 is connected with the gas detection device 3. Long conduit 8 is immersed in the pipe section length below the liquid surface in the gas washing bottle device 4 and is 0.9cm. The short conduit 17 is not in contact with the liquid in the gas washing bottle device 4 .

[0037] The gas washing bottle device 4 includes a stainless steel bottle body 11 , a rubber stopper 10 and a U-shaped tube 12 , the rubber stopper 10 covers the mouth of the glass bot...

Embodiment 3

[0039] Embodiment 3 of the present invention: a detection method for non-condensable gas in steam, including a qualitative detection method, appropriately increasing the discharge of water vapor to be tested, and increasing the distance between the first right angle tube 6 and the steam discharge port by adjusting the distance between The amount of water vapor sucked into the gas washing bottle device 4; the non-condensable gas is accumulated in the gas washing bottle device 4 and the entire measuring pipeline. The state of the gas inhalation gas detection device 3 is judged by the air bubbles sucked in the gas washing bottle device 4, and the water vapor suction amount and the air supplementary amount are compared by comparing the values of the two flowmeters before and after the gas washing bottle device 4. When the measurement time is longer than 3 minutes and the measurement value of the gas detection device 3 is always zero, it can be judged that there is no CO leaked in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com