A kind of sound-insulating multi-layer coated knitted fabric

A technology of knitted fabrics and film covering, applied in the field of knitted fabrics, can solve problems such as no reports, and achieve the effects of improving sound absorption characteristics, good sound insulation effect, and good sound absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

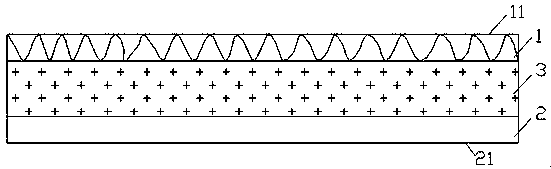

[0029] Such as figure 1 Shown is a schematic diagram of the overall structure of the present invention, a sound-insulating multilayer film-coated knitted fabric, consisting of a surface layer 1, a connecting layer 3 and an inner layer 2, and the surface layer 1 and the inner layer 2 are connected to the upper and lower two layers of the connecting layer 3 by weaving. End face; the outer surface of the surface layer 1 is covered with a polyurethane film a11, and the outer surface of the inner layer 2 is covered with a polyurethane film b21;

[0030] The surface layer 1 adopts the double-twisted filaments of aluminum fiber filaments and hollow nylon filaments; the present invention selects hollow nylon fibers and alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com