Energy absorption type front lower protective beam device for automobile

A technology for protective beams and automobiles, applied in the direction of bumpers, etc., can solve the problems of poor fuel economy, increased material, and poor yield resistance of carbon steel, and achieve the effect of high collision compatibility, ensuring safety, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

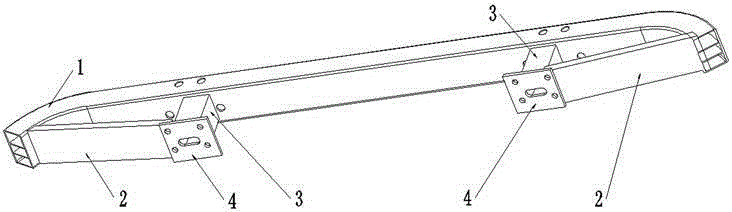

[0013] Such as figure 1 An energy-absorbing automobile front lower protective beam device shown is composed of a metal tubular beam 1, a reinforced inclined support beam 2, an energy-absorbing box 3 and a bracket 4 for connecting the chassis, and the metal tubular beam 1 and the bracket for connecting the chassis 4 are integrally connected by bolts or welded through the energy-absorbing box 3; a reinforced oblique support beam 2 is provided between the bracket 4 for connecting the chassis and the metal tubular beam 1; the energy-absorbing box 3 is made of sheet metal, and the energy-absorbing box 3 is a hollow structure. The metal tubular beam 1 and the reinforced inclined support beam 2 are made of carbon steel plate or light metal material of aluminum alloy series.

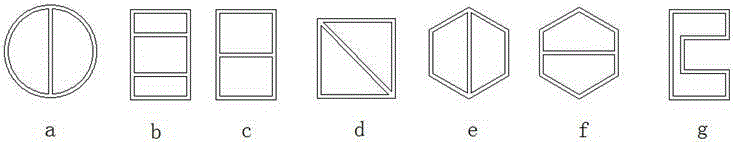

[0014] Such as figure 2 As shown, there are 1-2 reinforcement plates along the length direction inside the metal tubular beam. Without considering the reinforcement plates, the cross-sectional shape of the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com