An industrial steel slag recovery iron metal equipment

A steel slag recovery and iron metal technology, which is applied in recycling technology, solid separation, magnetic separation, etc., can solve the problems of low recovery of iron metal and other problems, and achieve the effects of easy collection, high efficiency and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

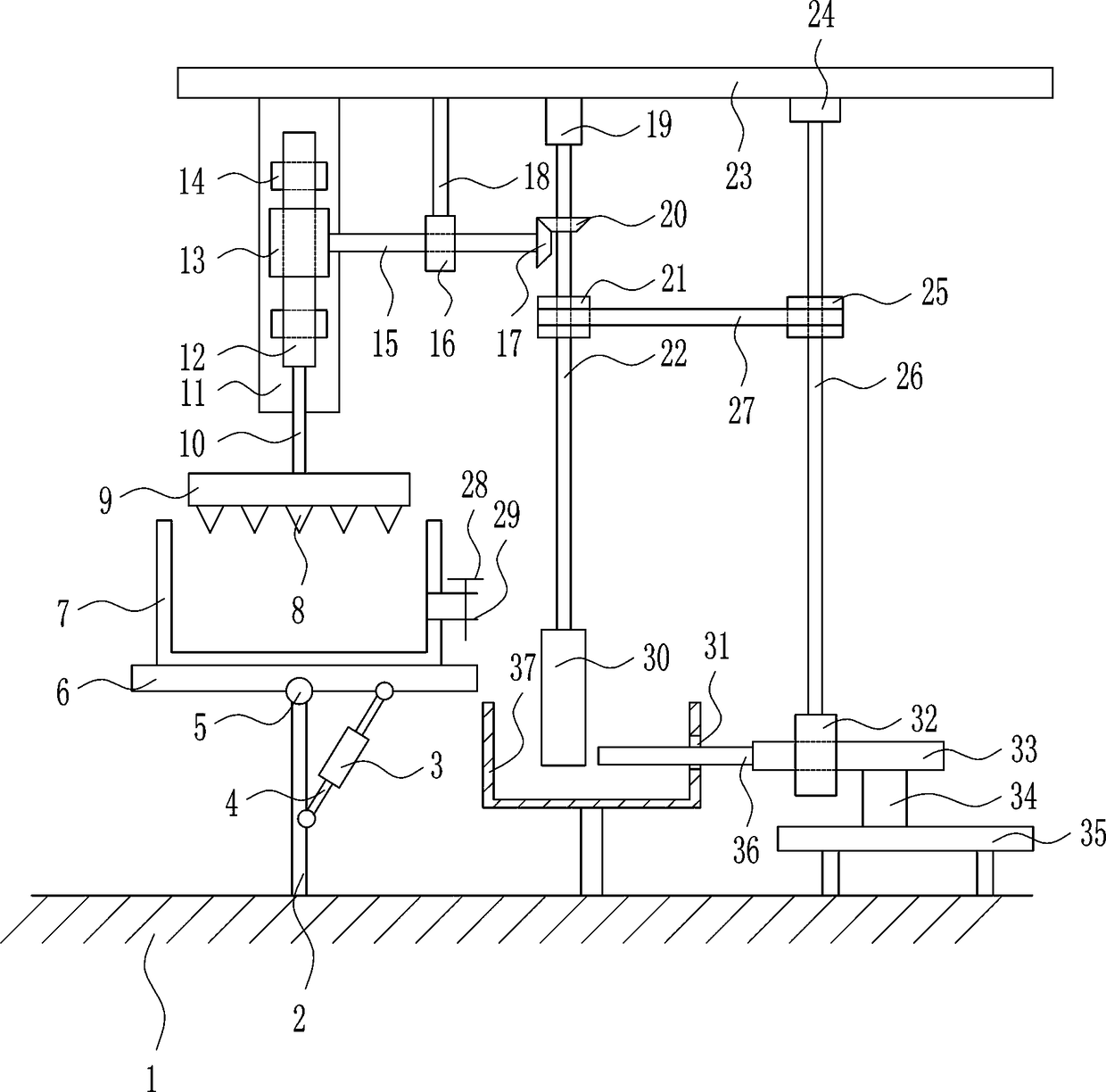

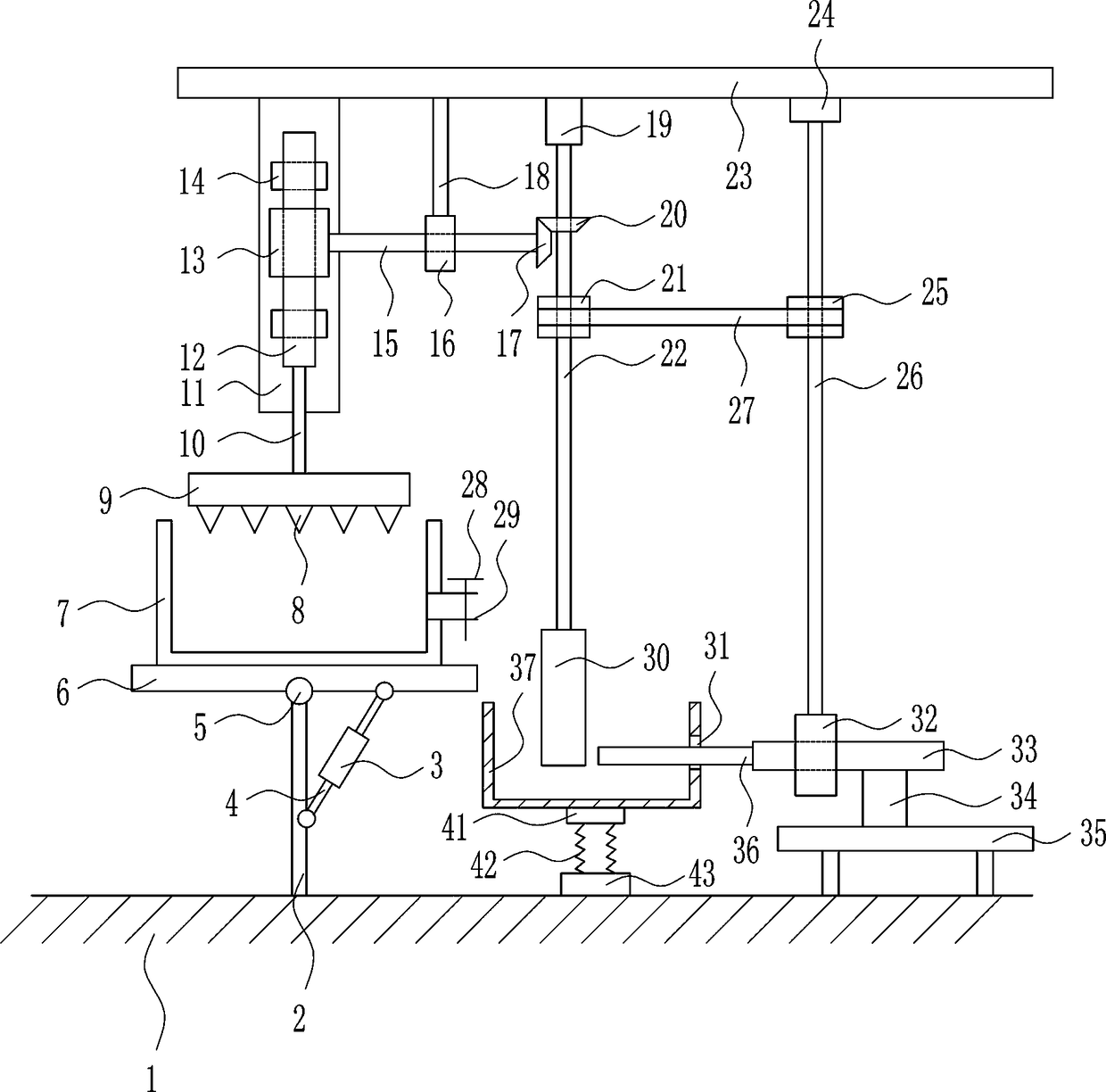

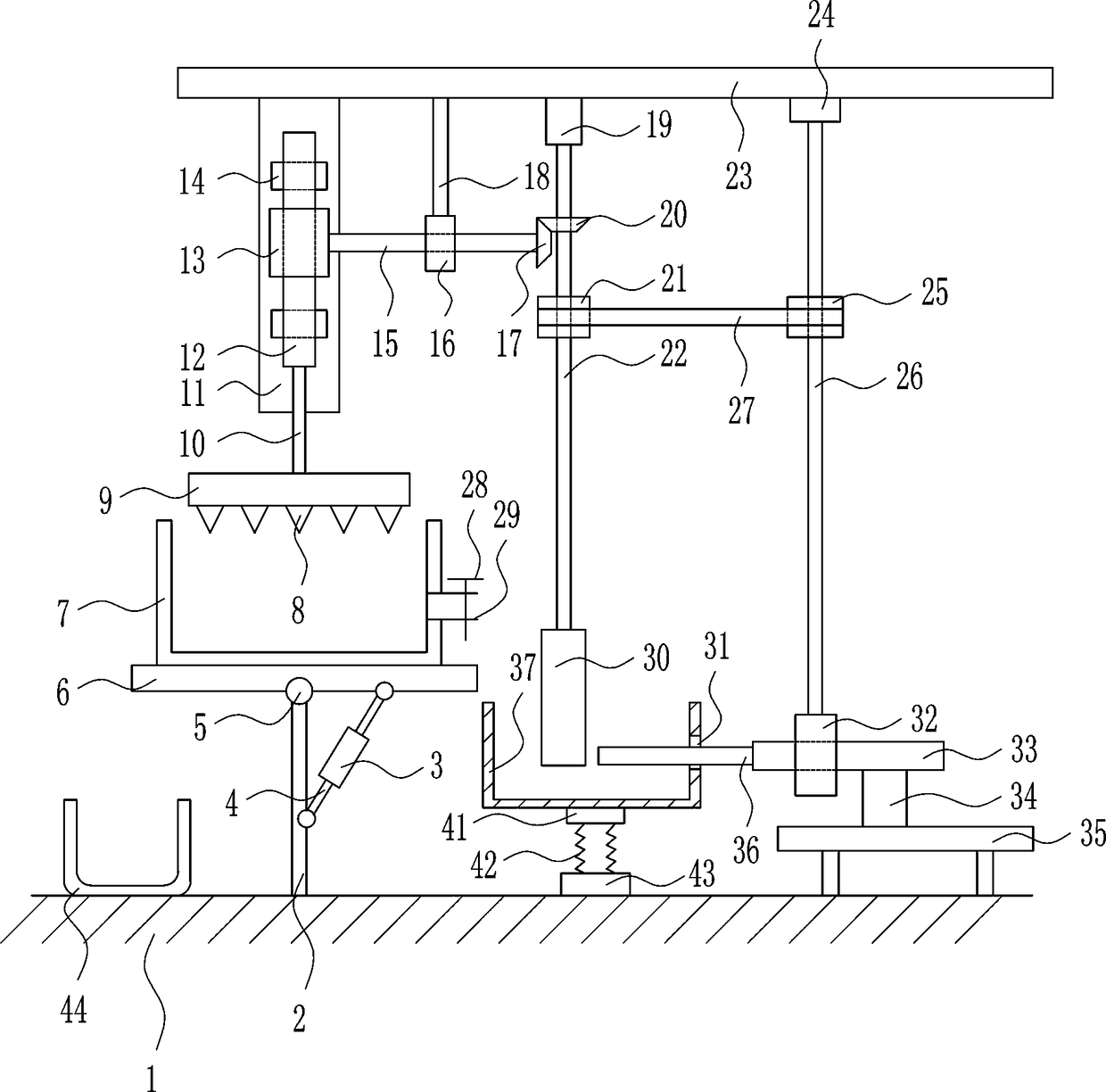

[0032] An industrial steel slag recovery iron metal equipment, such as Figure 1-6 As shown, it includes a first pole 2, a cylinder 3, a second pole 4, a hinged part, a placement plate 6, a crushing groove 7, a crushing tooth 8, a bottom plate 9, a third pole 10, a first slide rail 11, The first rack 12, the first gear 13, the first slider 14, the first rotating shaft 15, the first bearing seat 16, the first bevel gear 17, the fourth pole 18, the rotating motor 19, the second bevel gear 20, First pulley 21, second rotating shaft 22, top plate 23, second bearing seat 24, second pulley 25, third rotating shaft 26, flat belt 27, valve 28, discharge pipe 29, stirring rod 30, second gear 32, The second rack 33, the second slide block 34, the second slide rail 35, the magnet block 36 and the placement groove 37; the ground 1 is connected with the first pole 2 by means of screw connection, and the top of the first pole 2 is placed on the top of the ground 1 Plate 6 is connected by h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com