A kind of adsorption catalytic exhaust gas treatment system and method

A waste gas treatment, adsorption and catalysis technology, applied in the direction of gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of low efficiency and poor treatment effect, and achieve the effect of comprehensive recycling and optimization of painting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

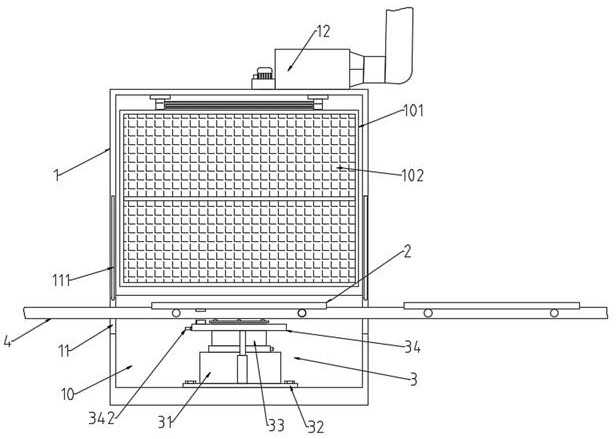

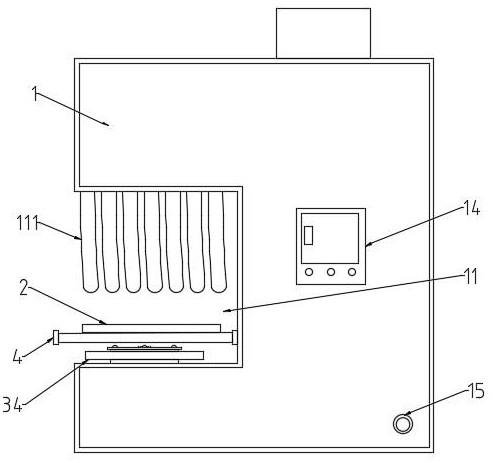

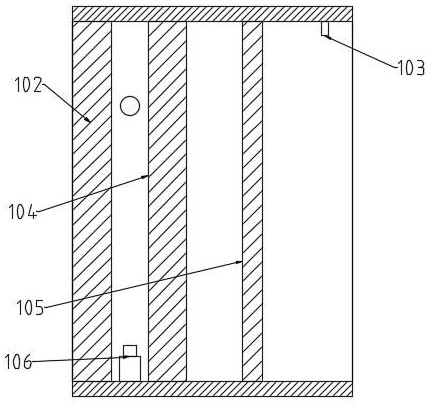

[0033] Combine below Figure 1-8 The present invention will be described in detail.

[0034] An adsorption-catalyzed waste gas treatment system of the present invention includes a paint spraying module 1, the paint spraying module 1 is a cabinet, on which is provided a treatment liquid interface 15 and an electric control box 14, and the paint spraying module 1 is provided with a paint spraying chamber 10, The filter assembly, the catalytic assembly 105, the spray assembly 103 and the adsorption assembly, the transmission line assembly 4 passes through the paint spraying chamber 10, the paint spraying table 2 is placed on the transmission line assembly 4, and the paint spraying chamber 10 has two sides for the transmission line The opening 11 through which the assembly 4 passes. There is a curtain 111 hanging at the opening 11 to prevent the rapid overflow of exhaust gas. The transmission line assembly 4 includes belt lines on both sides, which are driven by a motor, and trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com