A device for controlling furnace temperature overshoot

A technology for controlling furnace and overshooting, which is applied in the direction of heat treatment process control, furnace, heat treatment furnace, etc., can solve problems such as punching temperature, affecting workpiece quality uniformity, and temperature uniformity that cannot meet the standard, so as to reduce quality differences and ensure Overall Quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

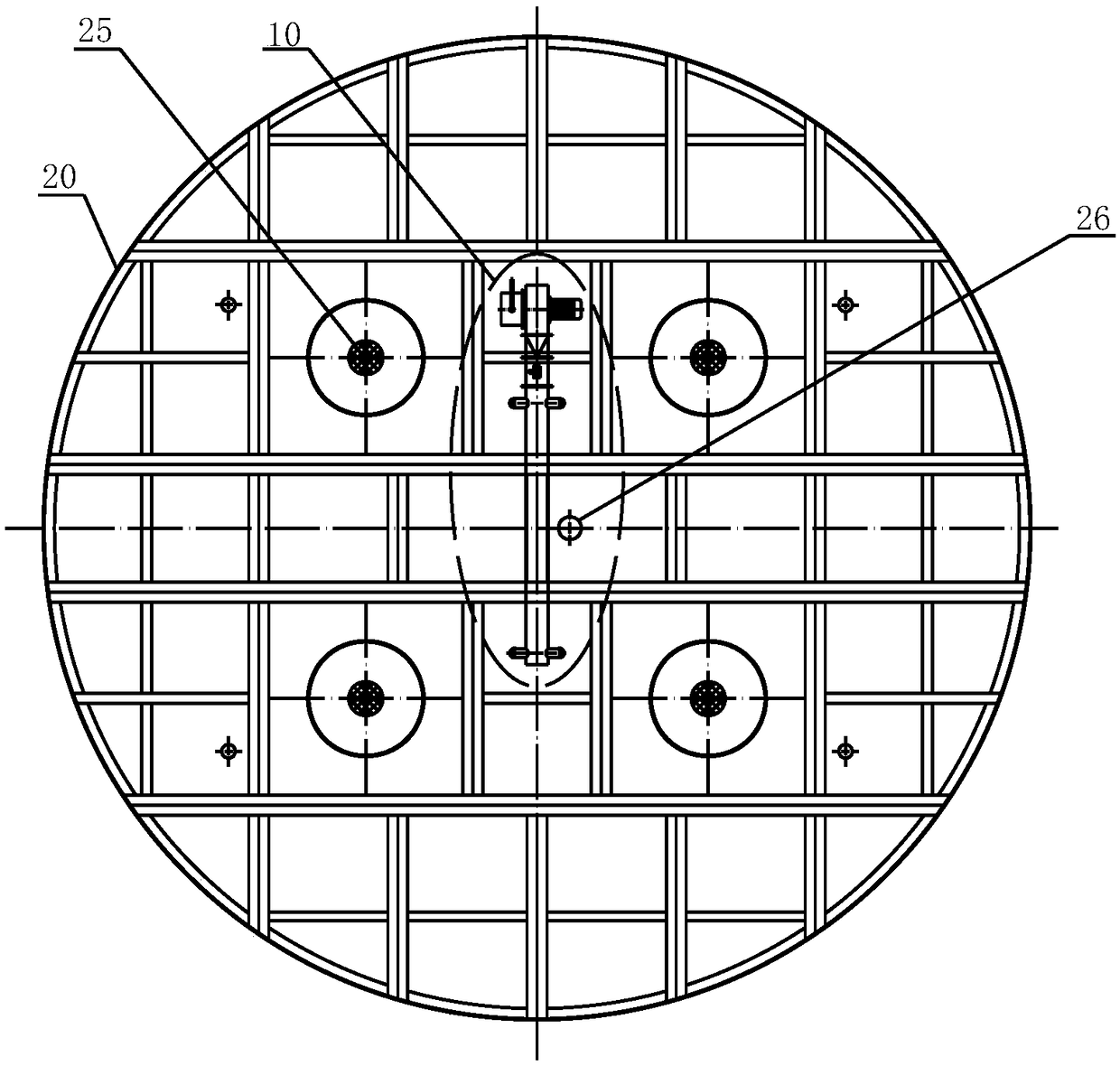

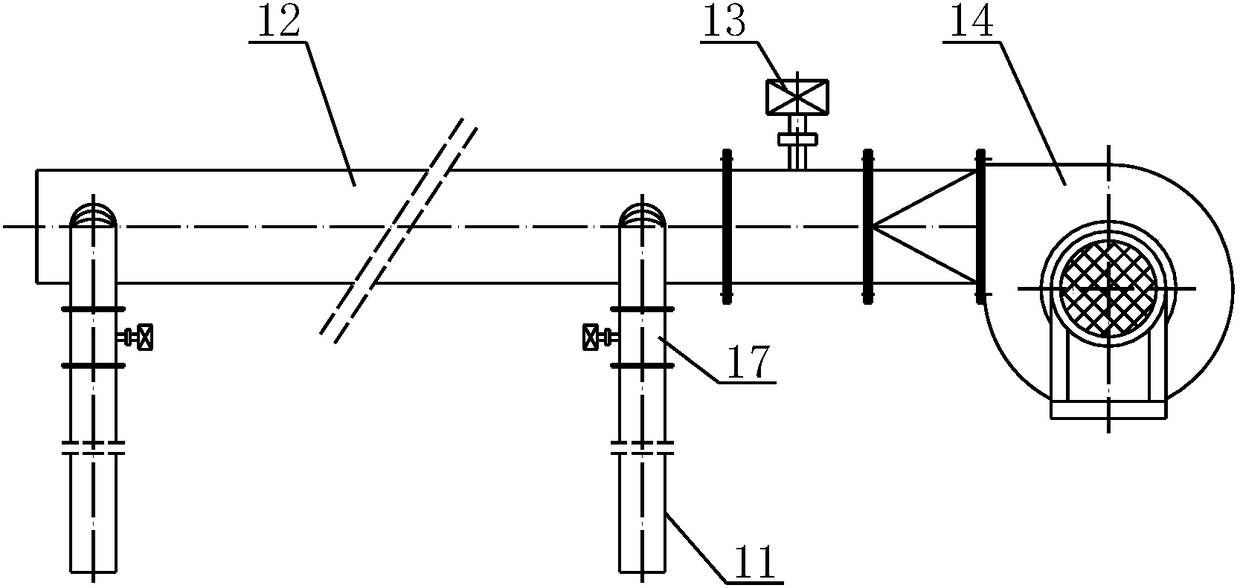

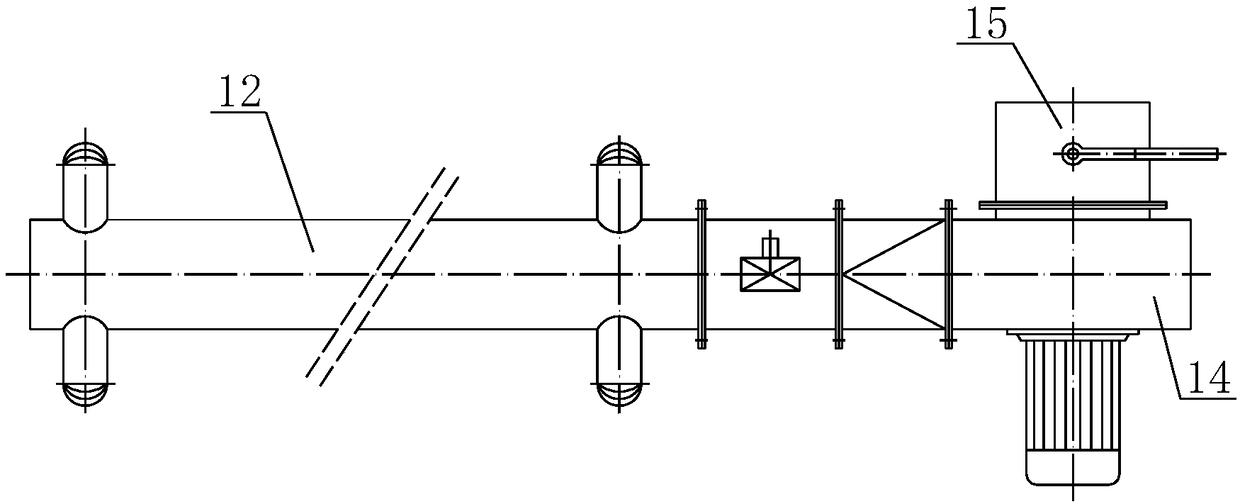

[0025] Refer to figure 1 , A device for controlling furnace temperature overshoot, the device is set on the top 20 of the solid solution aging comprehensive furnace, the device includes a cold air mixing device 10, please refer to figure 2 The cold air mixing device 10 includes a cold air main pipe 12 arranged on the top of the furnace, a cold air branch pipe 11 connected to the cold air main pipe 12, and a blower 14 connected to the cold air main pipe 12, and the air outlet of the cold air branch pipe 11 is located on the furnace top On the side facing the inside of the solid solution aging comprehensive furnace, an outlet regulating valve 13 is provided at the outlet of the blower 14, and at least one cold air branch pipe is provided. In this embodiment, four cold air branch pipes 11 are provided, and each cold air branch pipe 11 is provided with a sub-regulating valve 17. The four cold air branch pipes are arranged on both sides of the cold air main pipe 12, with two cold air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com