Air volume control system for cooling fan of radiator

An air volume control system and fan control technology, applied in pump control, machine/engine, non-variable-capacity pump, etc., can solve the problems of shortened cruising range, shortened fan life, excess heat dissipation, etc., to increase cruising range, guarantee Heat dissipation requirements and the effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

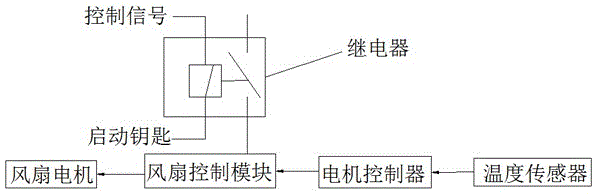

[0011] Such as figure 1 The cooling fan air volume control system of the radiator is shown in the figure. The fan control module receives the timely temperature information of the motor and the motor controller through the CAN network. When either temperature reaches the set temperature of the fan, the fan module uses PWM mode to Adjust the fan speed to meet the cooling requirements of the system.

[0012] For example, set the motor controller temperature control range: 40-50°C; motor temperature control range: 70-110°C; set the cooling fan speed adjustment range: 10%-100% according to the cooling capacity of the fan itself. The pulse duty cycle determines the fan speed. When the temperature of the motor controller reaches 40°C or the motor temperature reaches 70°C, the duty cycle of the PWM pulse width modulation is used to make the fan speed reach 10%. The fan speed is based on the temperature change of the two. During the working process, the higher temperature is used as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com