Vacuum Calibration Auxiliary Device and Thermal Distortion Correction Method for High Precision Star Sensor

A star sensor and auxiliary device technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of affecting the calibration accuracy, indistinguishability, thermal deformation, etc., and achieve the effects of ensuring stability, reducing influence, and isolating heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

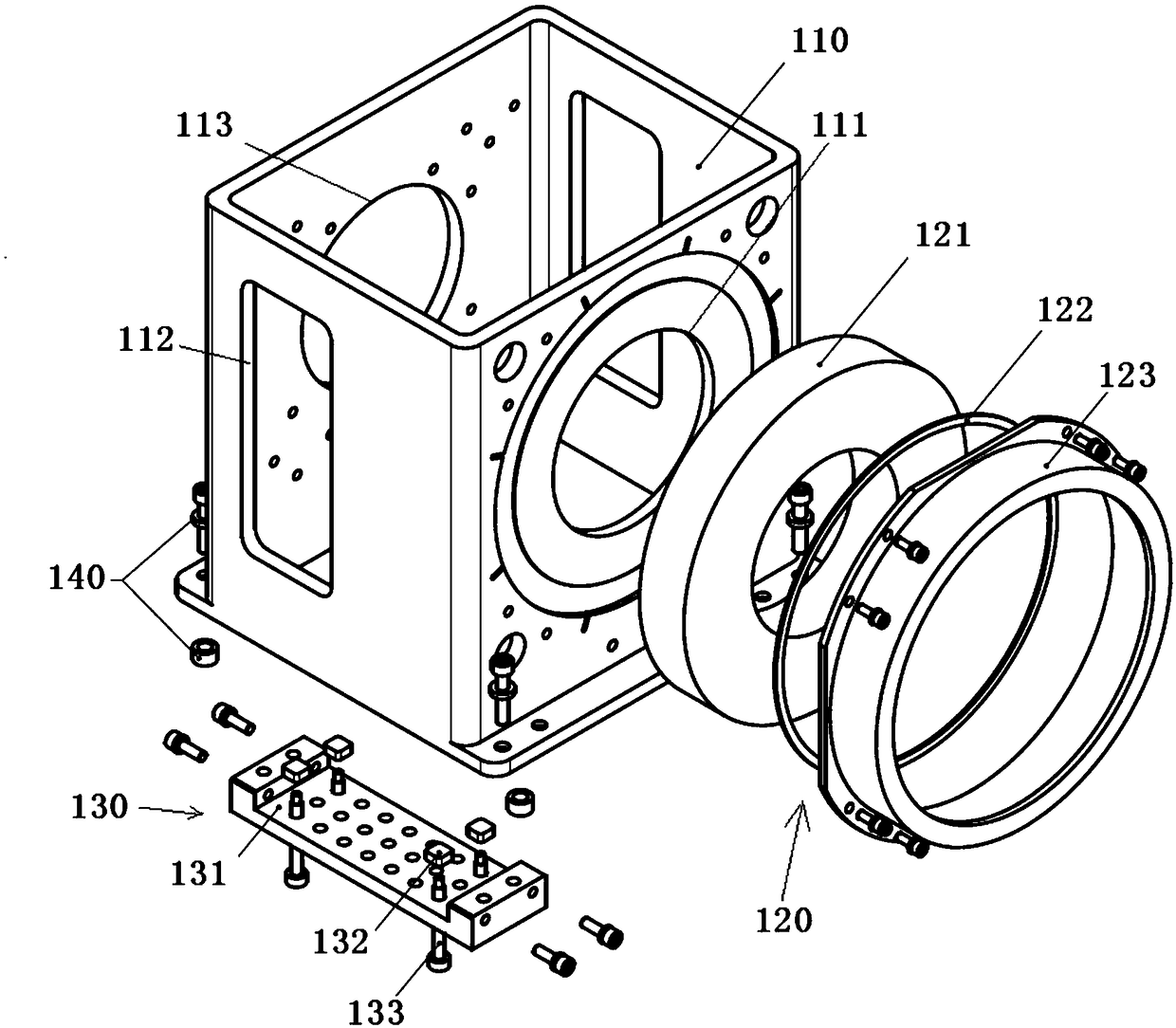

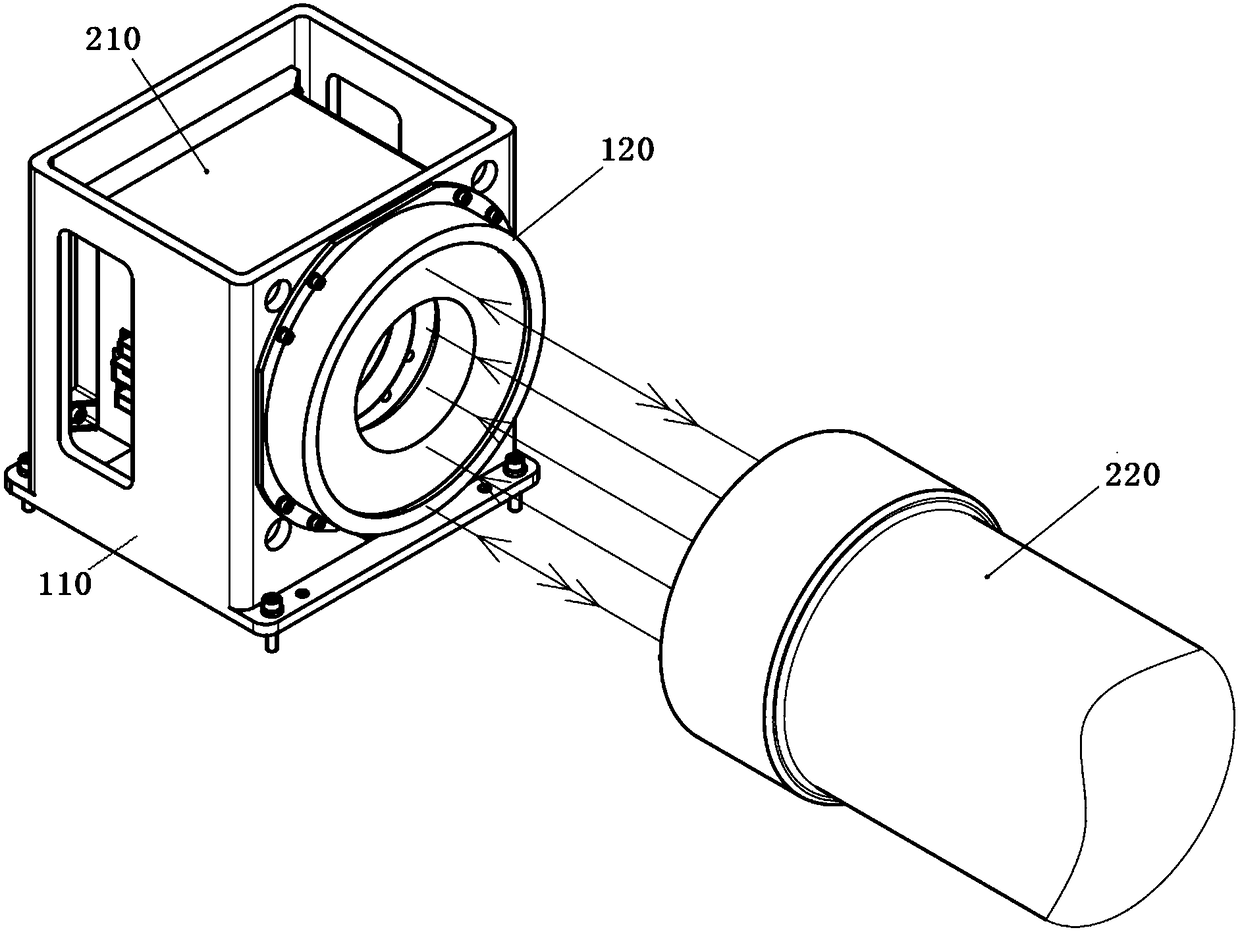

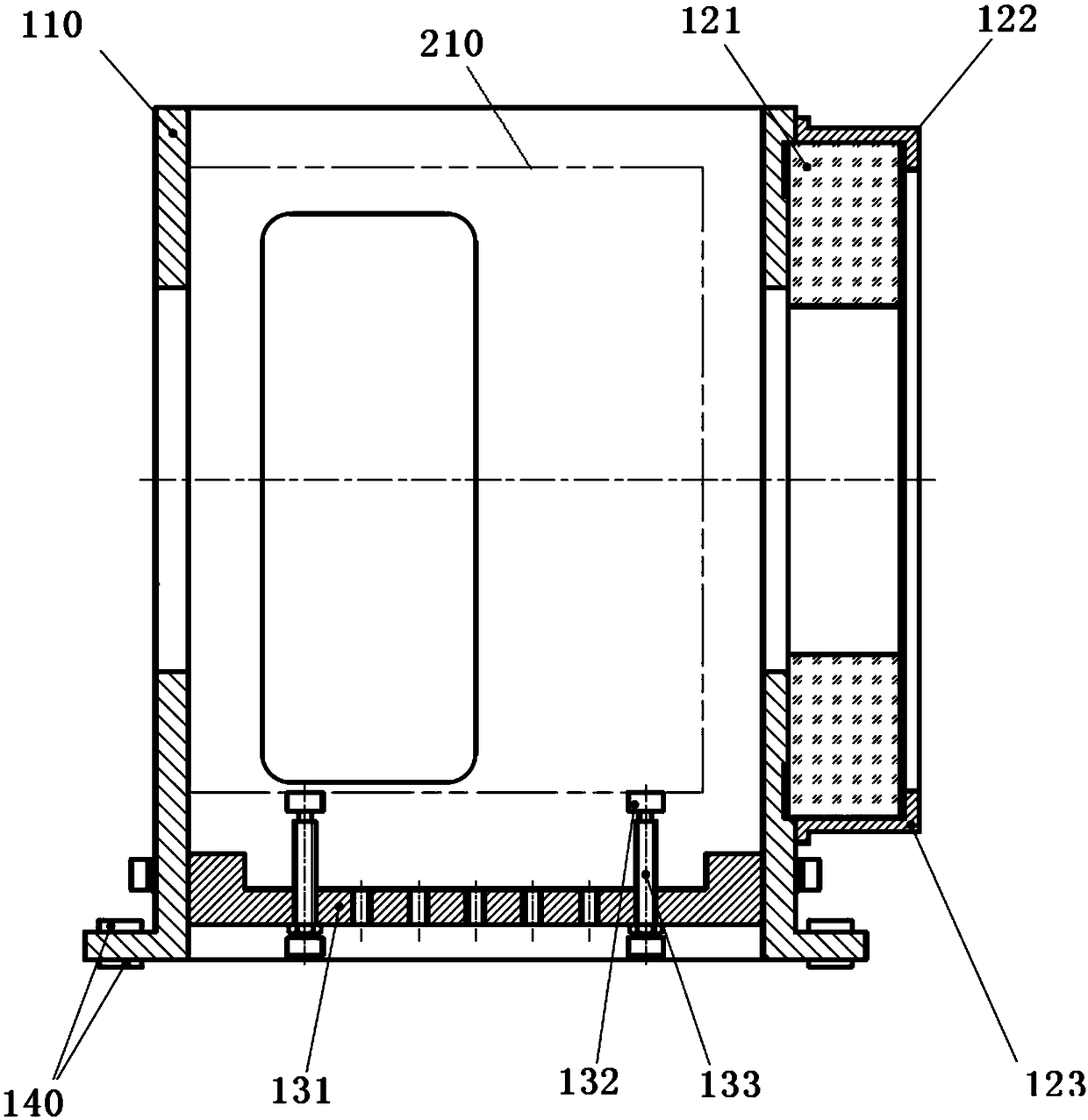

[0035] Such as figure 1 merge figure 2 , image 3 As shown, it is an embodiment of a vacuum calibration auxiliary device for a high-precision star sensor, which is connected to a turntable for vacuum calibration. The vacuum calibration auxiliary device for a high-precision star sensor includes: a main mounting frame 110, a mirror assembly 120 and auxiliary support frame 130.

[0036] The main mounting frame 110 adopts a cubic structure, and the interior is hollow to form an accommodating space. The star sensor 210 is arranged in the accommodating space of the main mounting frame 110, and is fastened with the main mounting frame 110 by screws to realize fixing with the main mounting frame 110 connect.

[0037] The main mounting frame 110 corresponds to the side wall of the light entrance of the star sensor 210 , the side wall is defined as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com