Pressurizing fatigue test device for large-capacity cavity or semi-enclosed cavity

A fatigue test, semi-closed technology, applied in measuring devices, using repetitive force/pulse force testing material strength, instruments, etc., can solve the problems of low loading rate and large measurement error, and achieve increased inflation and improved discharge. The effect of improving gas efficiency and improving the rate of inflation and deflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

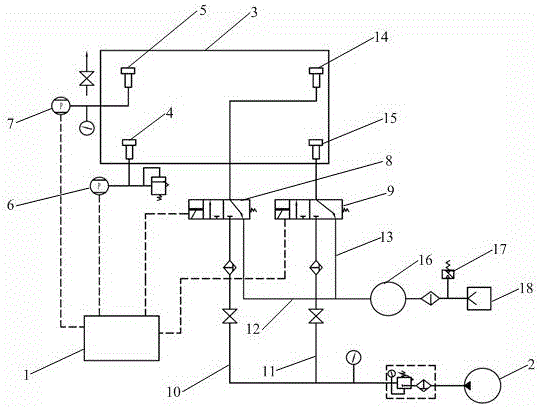

[0021] The embodiments will be described in detail below in conjunction with the accompanying drawings.

[0022] See attached figure 1 A pressure fatigue test device for a large-volume cavity or a semi-closed cavity includes a computer 1, an air compressor 2, a dual-channel measurement system, a dual-channel inflation and deflation control system, and a vacuum system. The computer 1 is connected to the test piece 3 through a dual-channel measurement system, the front end of the dual-channel inflation and deflation control system is connected to the air compressor 2, and the rear end is connected to the vacuum system. The air control system inflates and deflates the test piece 3.

[0023] The dual-channel measuring system includes pressure measuring point A4 and pressure measuring point B5 arranged on the test piece 3, a pressure sensor A6 and a pressure sensor B7, and the pressure sensor A6 is installed on the pressure measuring point A4 and connected with the computer 1 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com