Array substrate and display panel with embedded touch structure

An array substrate and display area technology, which is applied in the field of touch control, can solve problems such as large differences in wiring impedance and affect the normal display of display devices, and achieve the effects of improving display quality and uniform common voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

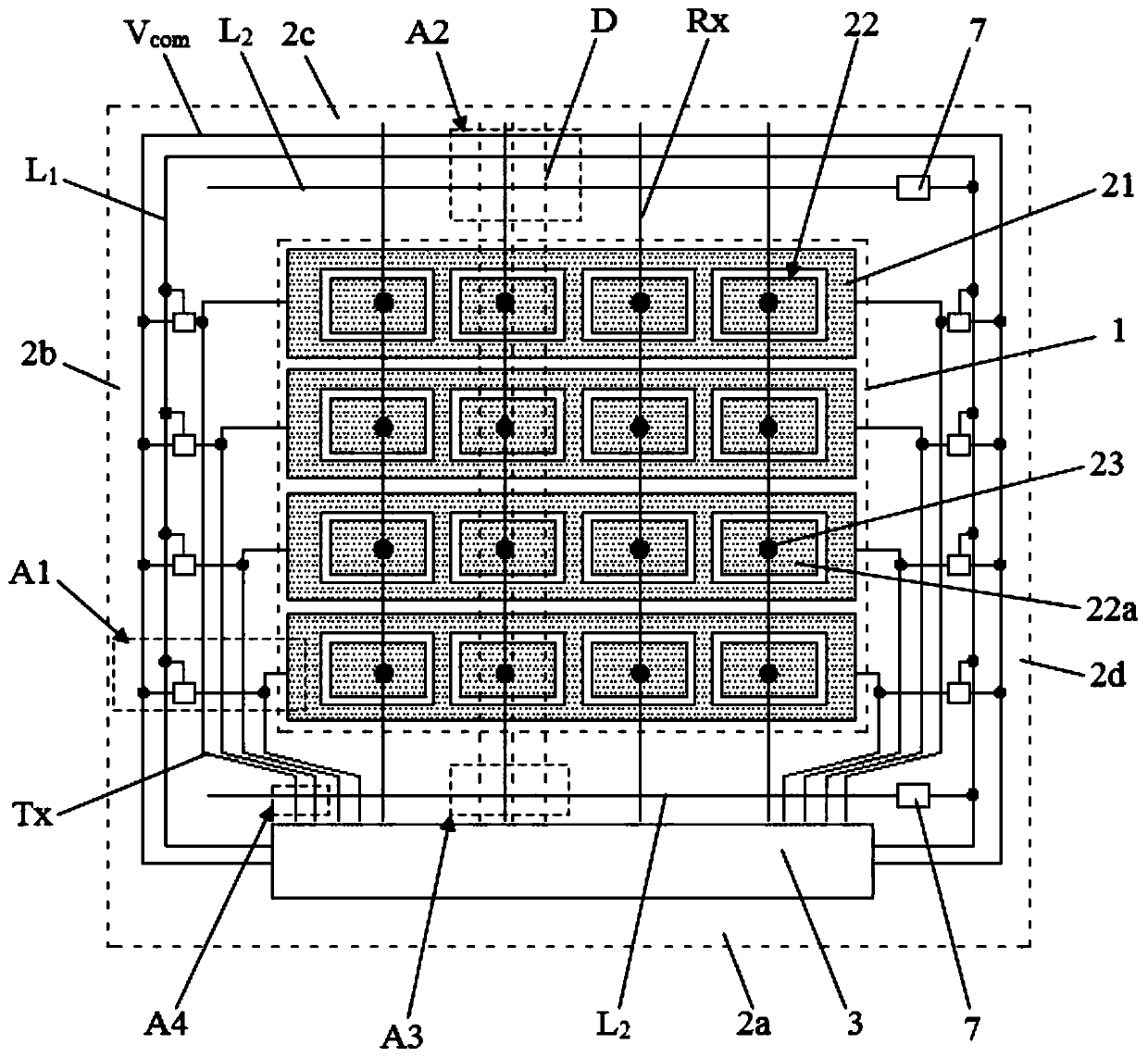

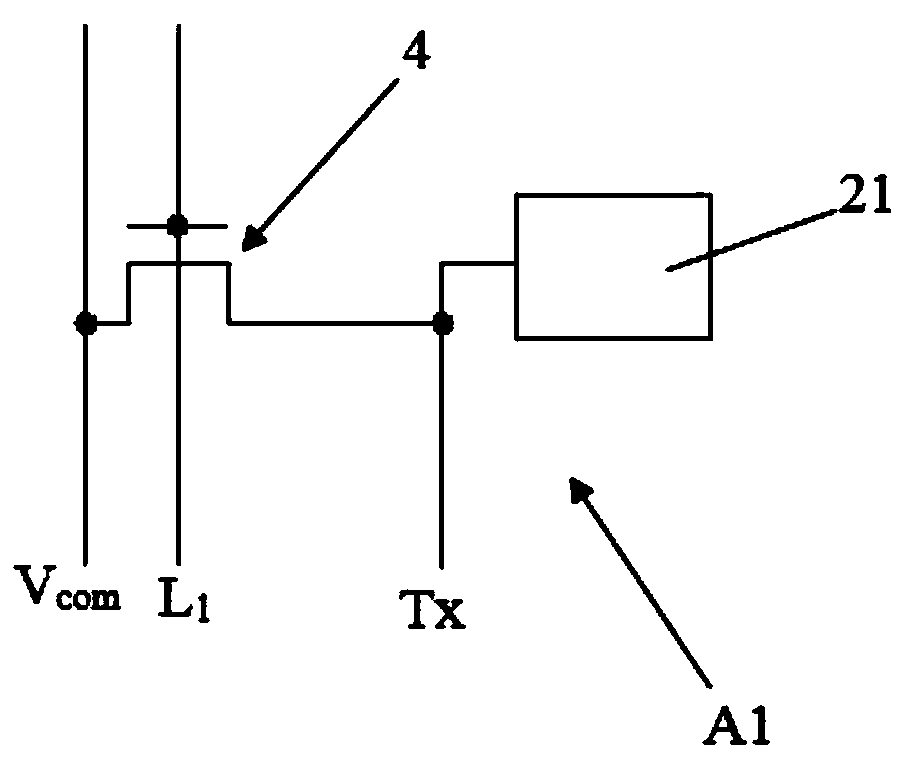

[0029] This embodiment provides an array substrate with embedded touch structure, refer to figure 1 and figure 2 The array substrate includes a data wiring layer 10 , a common electrode layer 20 and a touch wiring layer 30 sequentially disposed on a glass substrate 00 . A first insulating layer 40 is disposed between the pixel structure layer 10 and the common electrode layer 20 , and a second insulating layer 50 is disposed between the common electrode layer 20 and the touch wiring layer 30 .

[0030] Among them, such as figure 2 As shown, the data wiring layer 10 is provided with a plurality of parallel data lines D connected to the pixel unit, with figure 23 only exemplarily shows a part of the data line D, and the dotted line indicates that it is located under the common electrode layer 20 . The common electrode layer 20 is divided into a plurality of first electrodes 21 and a plurality of second electrodes 22 extending perpendicular to each other and insulated from ...

Embodiment 2

[0044] This embodiment firstly provides a display panel, such as Figure 7 As shown, the display panel is a liquid crystal display panel, which includes an array substrate 100 and a color filter substrate 200 disposed opposite to each other, and a liquid crystal layer 300 is filled between the array substrate 100 and the color filter substrate 200, wherein the array substrate 100 is an array substrate embedded with a touch structure as provided in Embodiment 1 above.

[0045] Another aspect of this embodiment is a display device, such as Figure 8 As shown, the display device includes a display panel 400 and a backlight module 500, the display panel 400 is arranged opposite to the backlight module 500, and the backlight module 500 provides a display light source to the display panel 400, so that The display panel 400 displays images. Wherein, the display panel 400 adopts the liquid crystal display panel provided in this embodiment.

[0046]To sum up, in the array substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com