Rheostat, motor and control method for motor

A technology of rheostats and control parts, which is applied in the direction of sliding contact resistors, electromechanical devices, electrical components, etc., can solve the problems of limited use, high manufacturing and maintenance costs, complex structures, etc., and achieve the effect of accurate and rapid resistance adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described below based on examples, but the present invention is not limited to these examples.

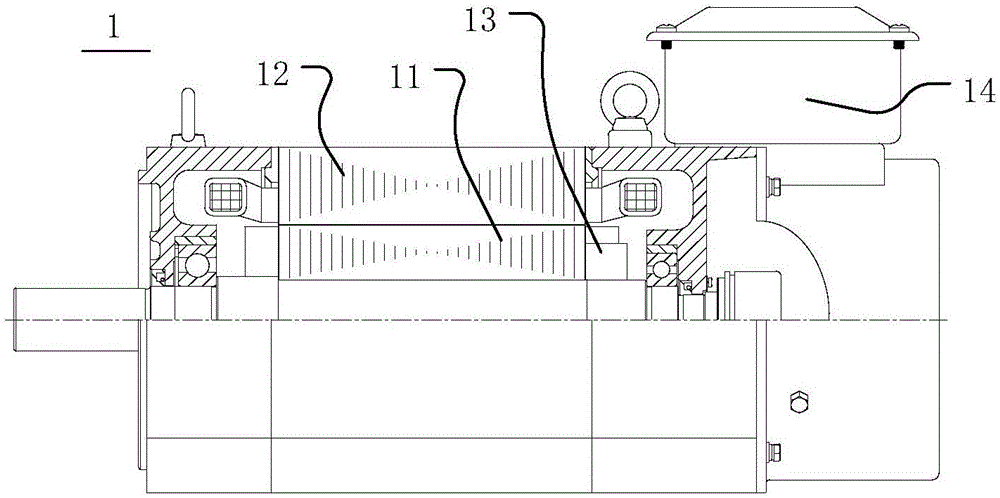

[0025] like figure 1 As shown, the motor 1 in the present application includes a rotor 11 and a stator 12 , the rotor 11 is arranged radially inside the stator 12 and can rotate relative to the stator 12 . According to the principle of the motor, when the motor rotor is connected in series with a resistor of an appropriate size, the starting torque of the motor can be equal to the maximum torque, and then as the speed increases, the resistance value of the required series resistor will gradually decrease until it reaches Cut off the series resistance after the rated speed.

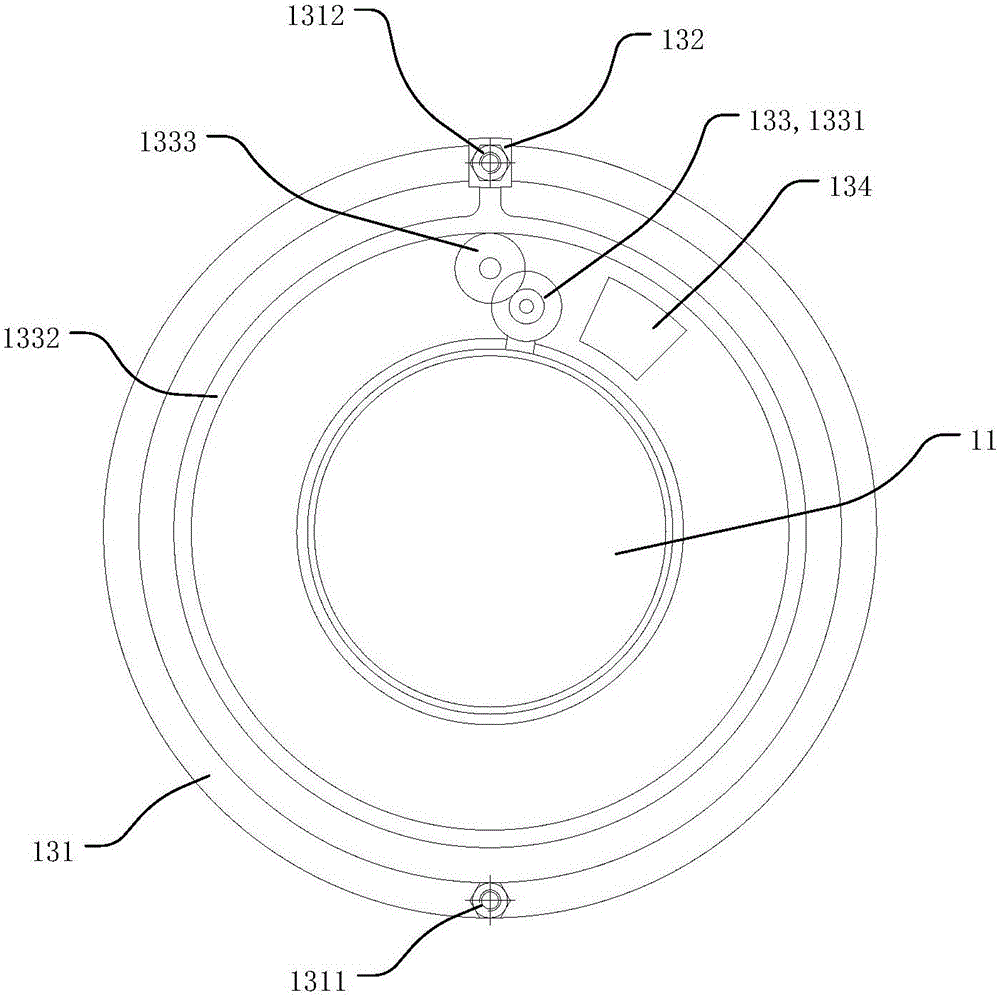

[0026] In the present application, a rheostat 13 is provided on the rotor 11, and the rheostat 13 can rotate together with the rotor 11, and the rheostat 13 is connected in series with the winding of the rotor 11. During the starting phase of the motor 1, the rheostat 13 The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com