Power transmission and transformation equipment management system

A technology of power transmission and transformation equipment and management system, applied in the field of power transmission and transformation equipment management system, can solve the problems of insufficient inspection, low level of intelligence, equipment failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

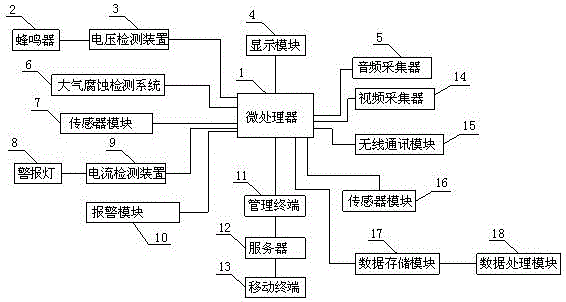

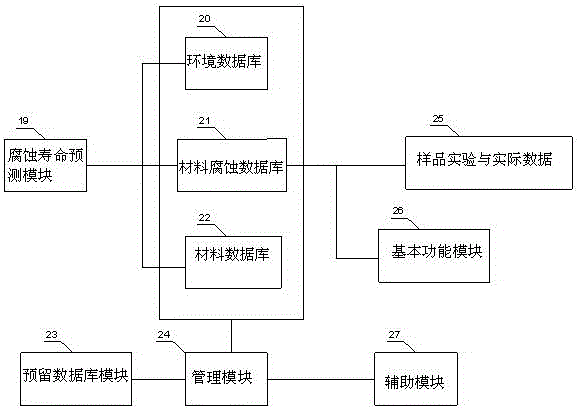

[0020] see Figure 1-2, a power transmission and transformation equipment management system, including a microprocessor 1, a buzzer 2, a voltage detection device 3, a display module 4, an audio collector 5, an atmospheric corrosion detection system 6, a sensor module 7, an alarm light 8, a current Detection device 9, alarm module 10, management terminal 11, server 12, mobile terminal 13, video collector 14, wireless communication module 15, sensor module 16, data storage module 17, data processing module 18, described voltage detection device 3, Display module 4, audio collector 5, atmospheric corrosion detection system 6, sensor module 7, current detection device 9, alarm module 10, management terminal 11, server 12, mobile terminal 13, video collector 14, wireless communication module 15, sensor Module 16 and data storage module 17 are all conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com