Method, processing machine and computer program product for image-based positioning of workpiece processing

A processing process and machine technology, applied in computer control, program control, metal processing, etc., can solve problems such as error-prone, time-consuming, inaccurate, etc., to save time and avoid errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

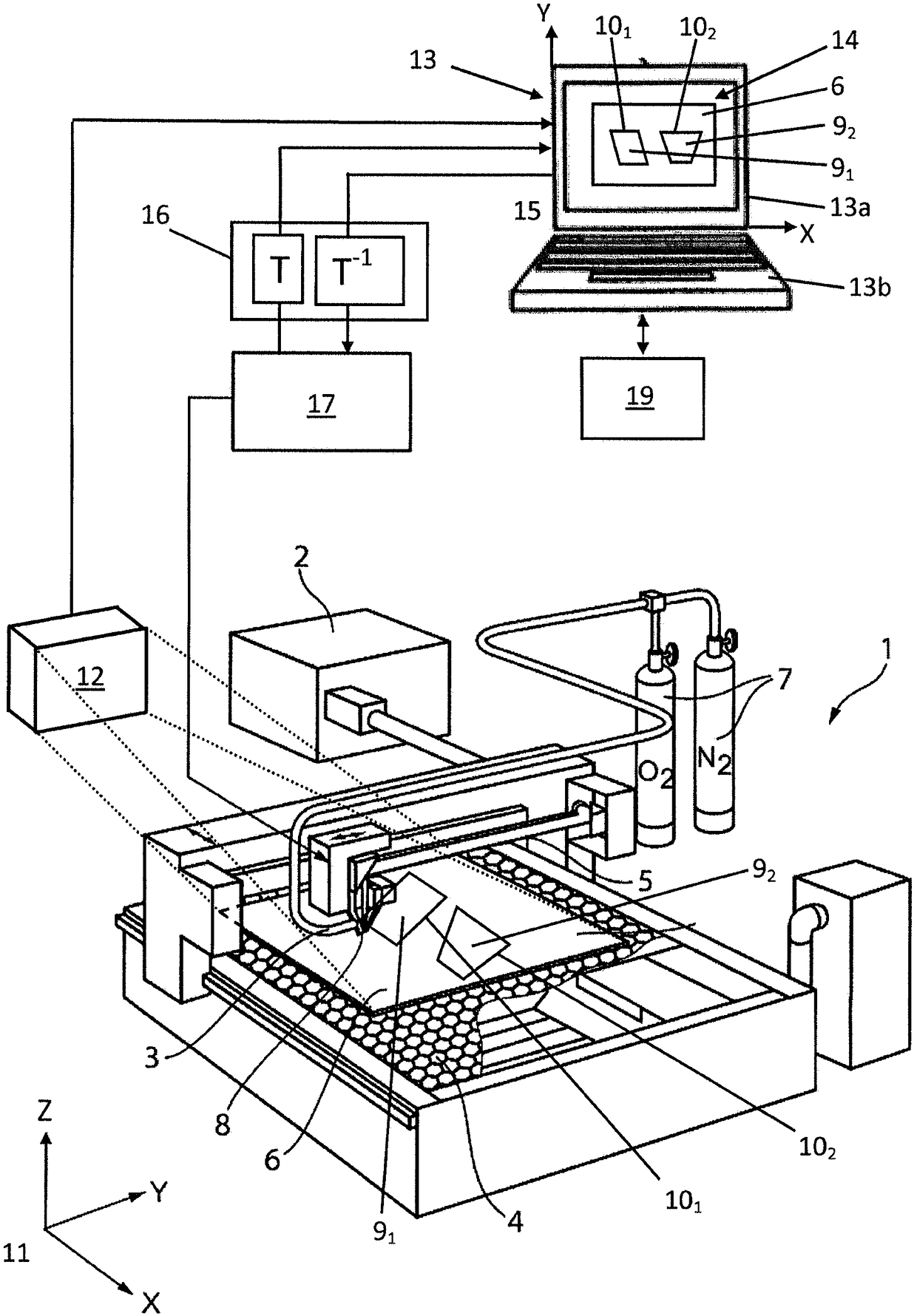

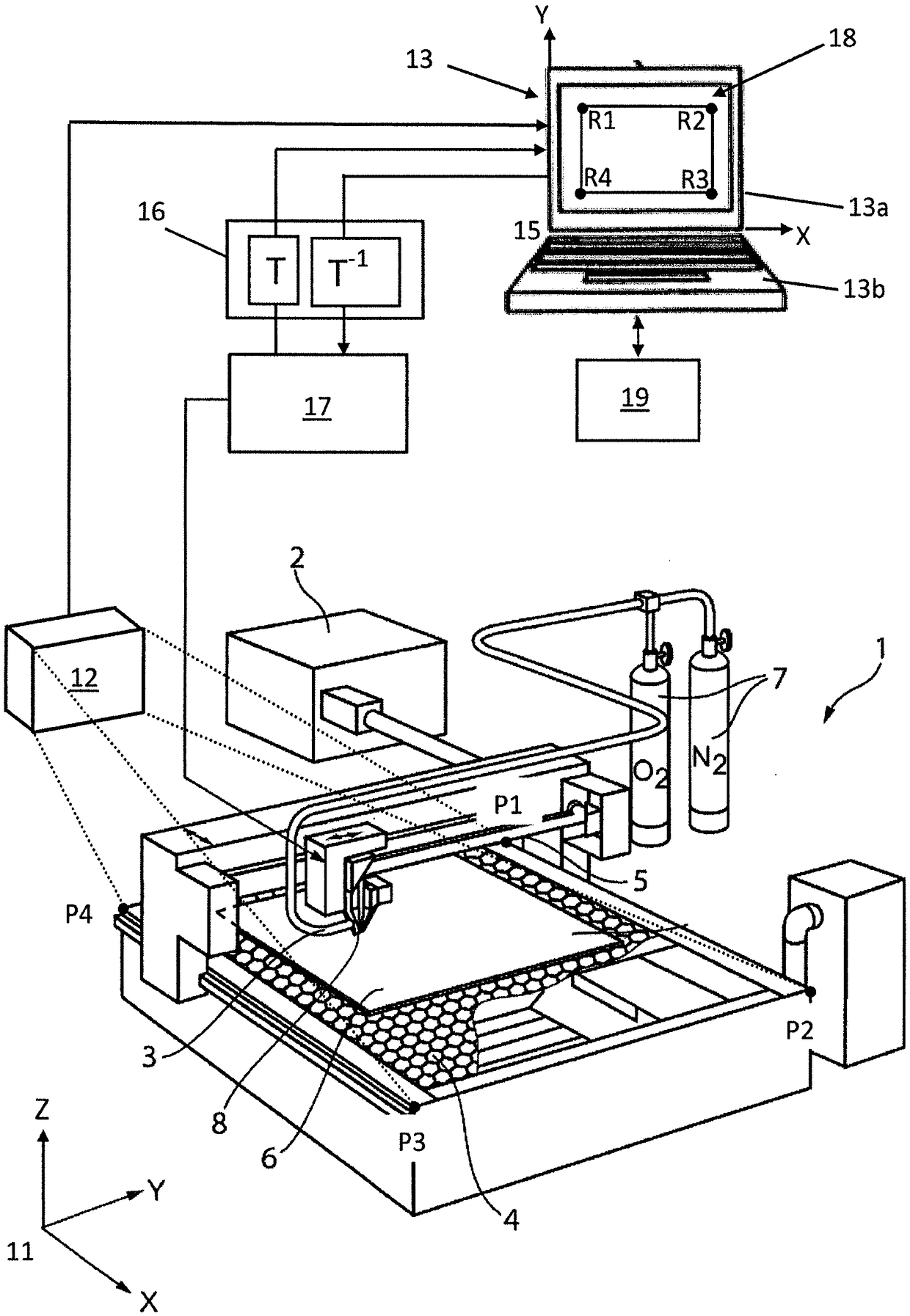

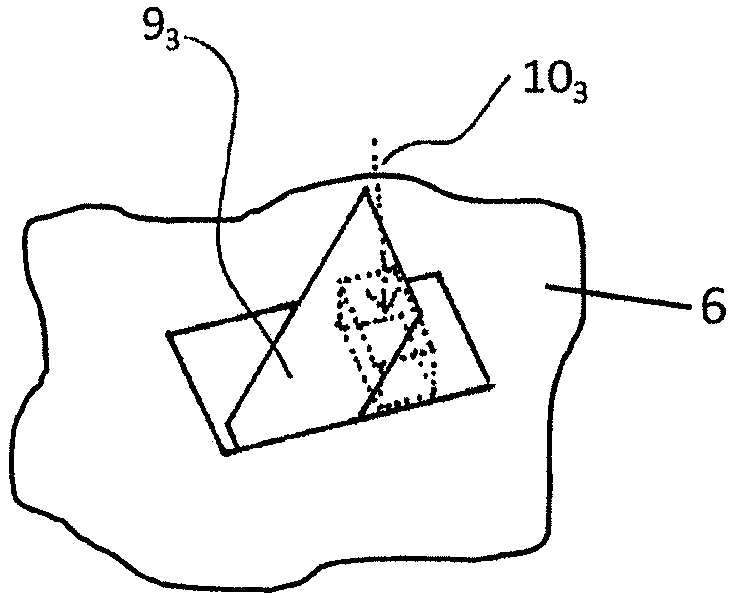

[0037] figure 1 The laser cutting machine 1 shown three-dimensionally as a platform machine includes, for example, a CO 2 A laser beam generator 2 of a laser, a diode laser or a solid-state laser, the laser cutting machine also includes a laser processing head 3 and a workpiece support 4 that can move in the X and Y directions. A laser beam 5 is generated in the laser beam generator 2 , which is guided from the laser beam generator 2 to the laser processing head 3 by means of an optical cable (not shown) or a deflection mirror (not shown). The laser beam 5 is directed by means of a focusing lens arranged in the laser processing head 3 onto a workpiece 6 (for example a sheet metal) located on the workpiece support 4 . Furthermore, the laser cutting machine 1 is supplied with process gases 7 , such as oxygen and nitrogen. A process gas 7 is fed to a process gas nozzle 8 of the laser machining head 3 , from which process gas emerges together with the laser beam 5 . Laser cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com