Badminton ball and manufacturing method thereof

A production method and badminton technology, applied in the field of badminton, can solve problems such as the inability to quantify the glue, the difficulty in standardizing the production process, and the inability to control the taper of the badminton well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

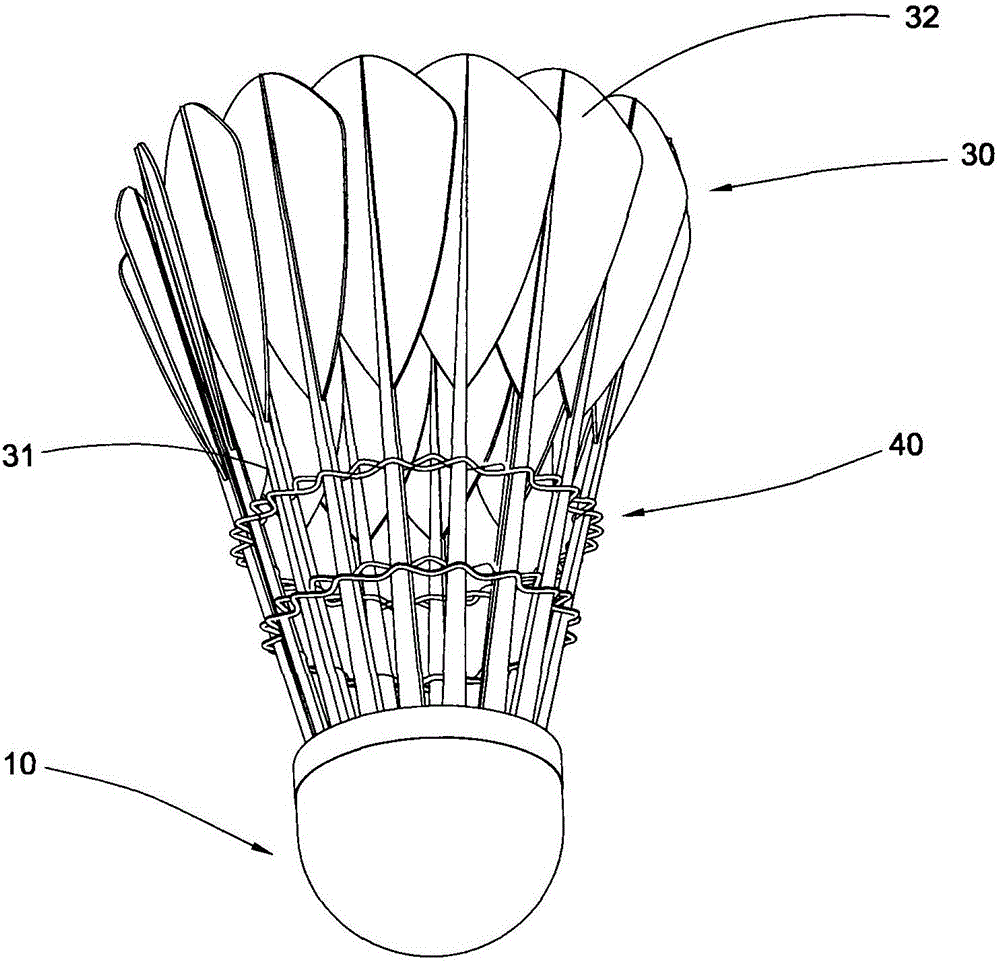

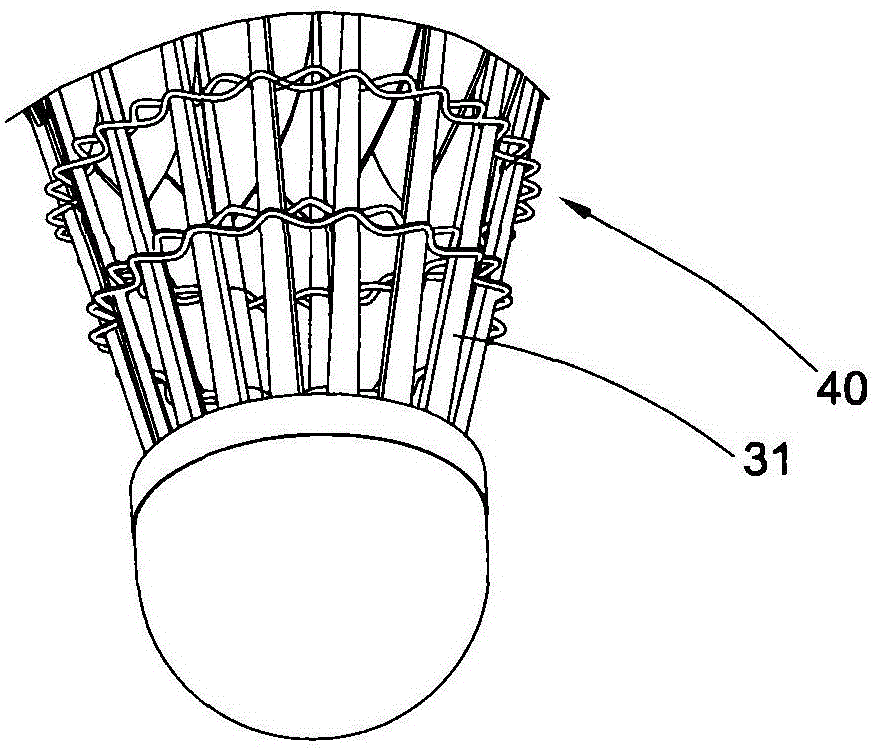

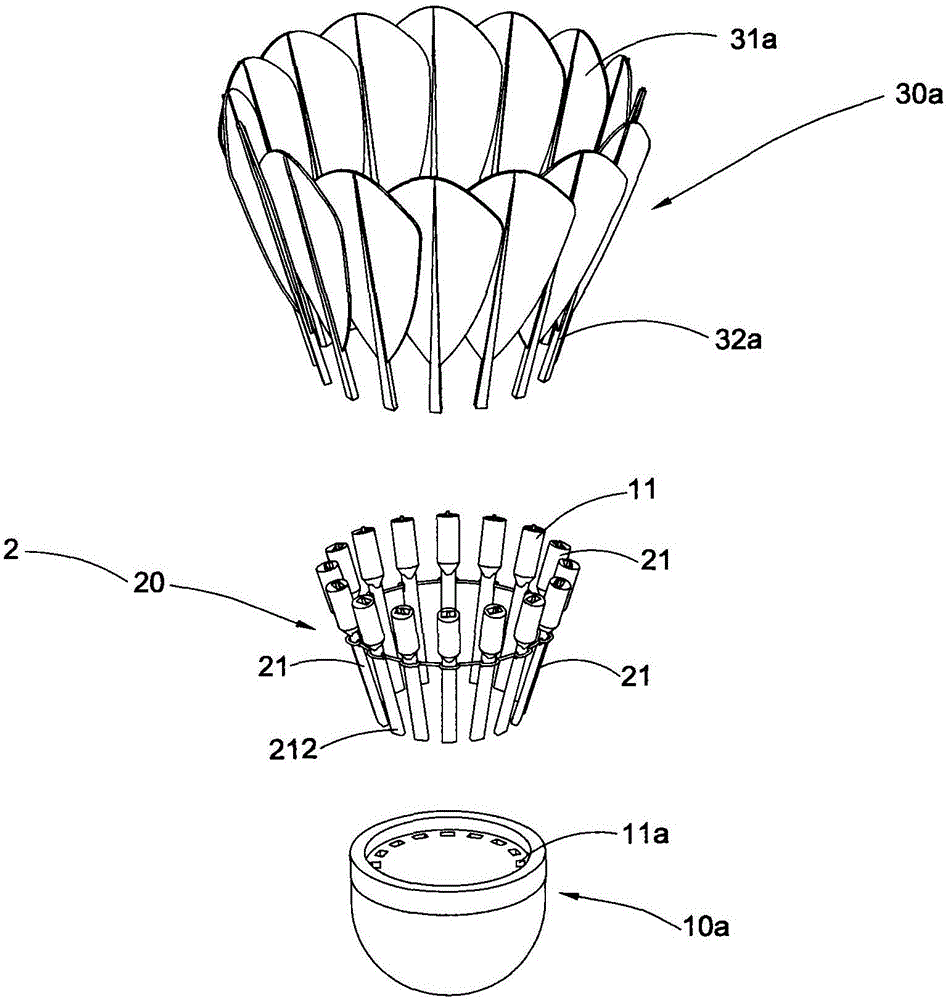

[0049] image 3 and Figure 4 Show the shuttlecock of the first embodiment of the present invention, as image 3 As shown, it includes a ball head 10a, a group of feathers 30a, and a connecting device 2, which connects the ball head 10a and the feathers 30a into one.

[0050] Such as image 3 As shown, the connection device 2 further includes a hair planting device 20 for connecting the feather 30a and the ball head 10a into one body. Described hair-planting device 20 further comprises a group of hair-planting rods 21 consistent with the number of feathers, each hair-planting rod 21 is connected with a feather 30a and the ball head 10a respectively, wherein, because the number of feathers 30a of a general shuttlecock is ten Correspondingly, the number of the hair-planting rods 21 is sixteen. Of course, the number of the hair-planting rods 21 can be increased or decreased correspondingly with the number of specific feathers 30a. Each hair-planting rod 21 has a hair-planting...

Embodiment 2

[0066] Figure 5 A shuttlecock showing a second embodiment of the present invention includes a head 10b, a set of feathers 30a, and a connecting device 2b that connects the head 10a and the feathers 30a into one body to form a badminton. The feathers in the shuttlecock in this embodiment are the same as those in Embodiment 1, but the connecting device 2b has some changes.

[0067] Such as Figure 5 As shown, the connecting device 2b includes a hair-planting device 20b for connecting the feather 30a and the ball head 10a, wherein the hair-planting device 20b includes a group of hair-planting rods 21b consistent with the number of the feathers 30a and a hair-planting rod 21b that connects the feather 30a It is worth mentioning that the number of connecting ribs 22 connected in series with the hair planting rods can be increased or decreased according to specific conditions, and the shape can also be changed accordingly. That is to say, the connecting rib 22b is used to replac...

Embodiment 3

[0080] Figure 6 to Figure 8 Shown is a shuttlecock according to a third embodiment of the present invention, which includes a head 10b, a set of feathers 30a, and a connecting device 2c that connects the head 10b and the feathers 30a into one body to form a badminton. In this implementation, some changes are made on the basis of the first and second embodiments, mainly on the connecting device 2c and the ball head 10b.

[0081] Such as Figure 6 As shown, the connecting device 2c includes a hair planting device 20c for connecting the feather 30a and the ball head 10b, wherein the hair planting device 20c includes a connecting piece 23c, and a group of hair planting rods 21c consistent with the number of feathers , wherein, the hair-planting rod 21c extends outward from the connecting part to form a cone, and the connecting part 23c and the hair-planting rod 21c are integrally formed.

[0082] Figure 7 It is a longitudinal sectional view of the hair planting device 20, ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com