Microfluidic Chip

A technology of microfluidic chips and microchannels, which is applied in the field of biological sciences, can solve the problems of high cost, limited application range, and high technical requirements, and achieve the effects of improving detection sensitivity, improving detection efficiency, and increasing detection concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

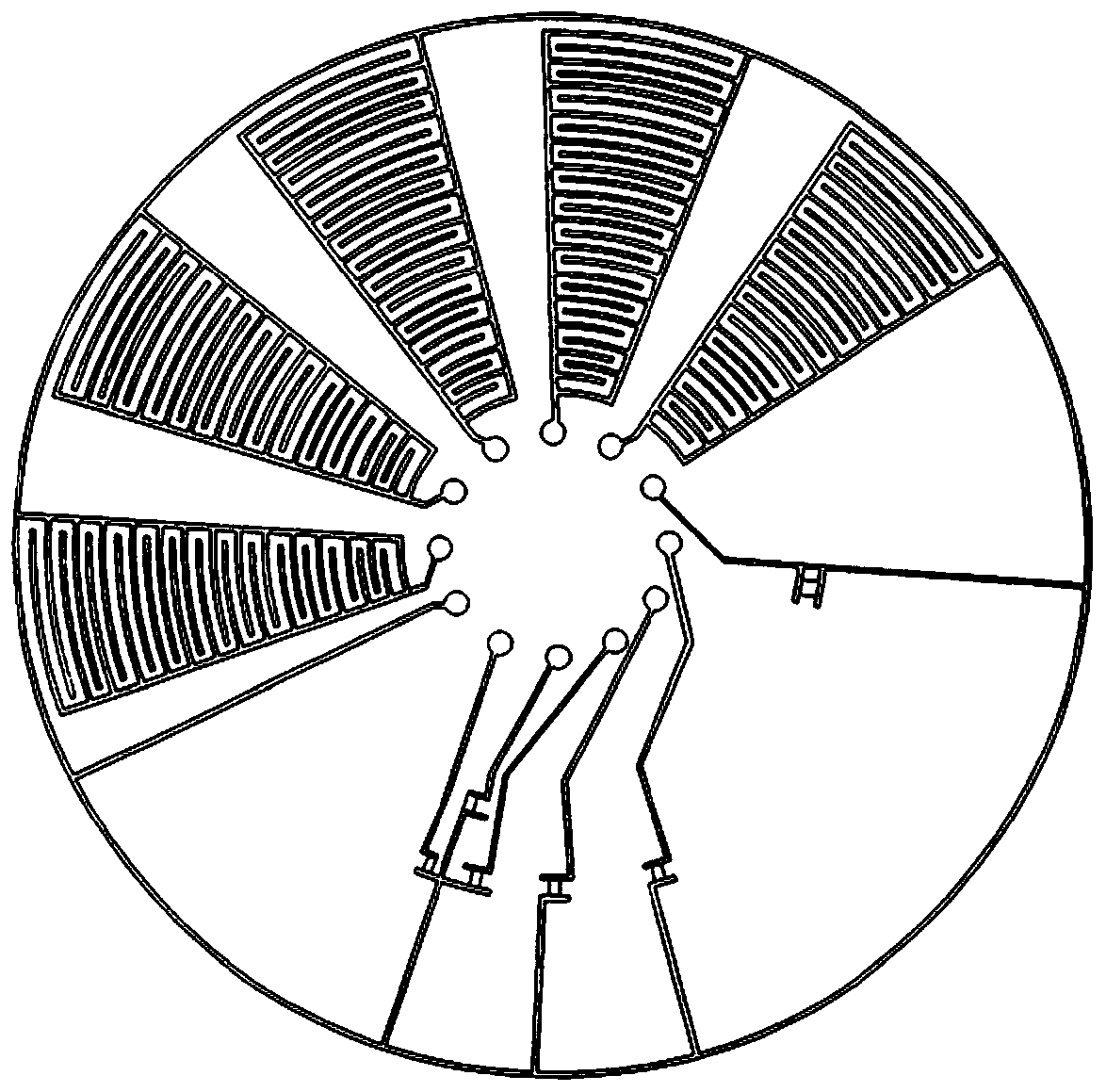

Image

Examples

Embodiment 1

[0051] The operating environment temperature is 25°C and the relative humidity is 66%.

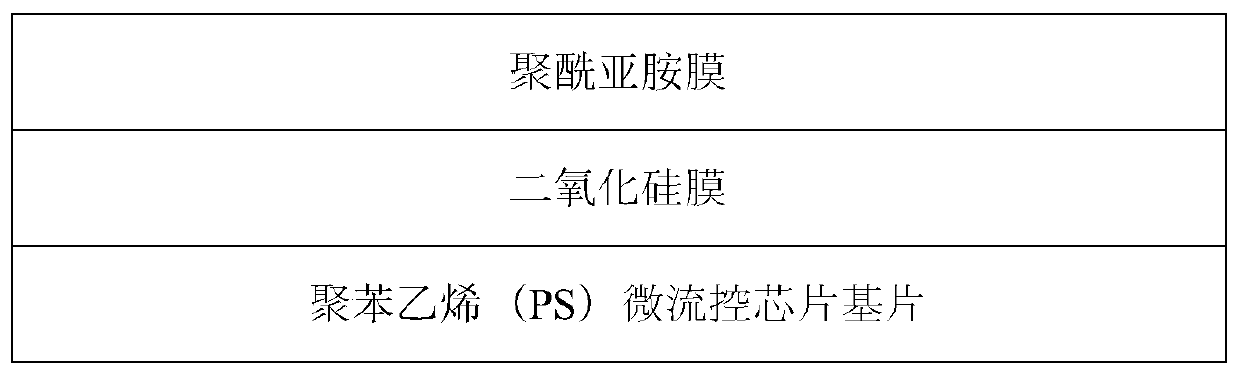

[0052] The polystyrene (PS) microfluidic chip substrate with the prefabricated microfluidic channel is sputter-coated to form a layer of silicon dioxide film on the substrate for future use.

[0053] Dissolve polyimide (PI) in CHCl 3 , configured as a 2% concentration of PI solution.

[0054] Use a microsampler to apply the above PI solution on the silicon dioxide film layer of the polystyrene (PS) microfluidic chip substrate, the PI solution spreads naturally and begins to form a transparent liquid film, accompanied by CHCl 3 volatilization, the transparent liquid film gradually solidifies, when CHCl 3 After all volatilization, a silicon dioxide film / polyimide composite film layer is formed on the base layer of the polystyrene (PS) microfluidic chip, and the outermost layer is a polyimide film. See figure 2 .

[0055] The substrate and the cover plate are sealed to form a microfluid...

Embodiment 2

[0058] The operating environment temperature is 25°C and the relative humidity is 42%.

[0059] The polycarbonate (PC) microfluidic chip substrate with the prefabricated microfluidic channel is sputter-coated to form a layer of silicon film on the base layer for future use.

[0060] Dissolve polyimide (PI) in CHCl 3 , configured as a 2% concentration of PI solution.

[0061] Use a microsampler to apply the above PI solution on the silicon film layer of the polycarbonate (PC) microfluidic chip substrate, the PI solution spreads naturally and begins to form a transparent liquid film, accompanied by CHCl 3 volatilization, the transparent liquid film gradually solidifies, when CHCl 3 After all volatilization, a silicon film / polyimide composite film layer is formed on the base layer of the polycarbonate (PC) microfluidic chip, and the outermost layer is a polyimide film.

[0062] The substrate and the cover plate are sealed to form a microfluidic chip.

[0063] The outermost po...

Embodiment 3

[0065] Test condition and operation are with embodiment 1, difference is:

[0066] The polystyrene (PS) microfluidic chip substrate with the prefabricated microfluidic channel is sputter-coated to form a layer of aluminum film on the base layer for future use.

[0067] Use a microsampler to coat the PI solution on the aluminum film layer of the polystyrene (PS) microfluidic chip substrate, the PI solution spreads naturally and begins to form a transparent liquid film, accompanied by CHCl 3 volatilization, the transparent liquid film gradually solidifies, when CHCl 3 After all volatilization, an aluminum film / polyimide composite film layer is formed on the base layer of the polystyrene (PS) microfluidic chip, and the outermost layer is a polyimide film.

[0068] The substrate and the cover plate are sealed to form a microfluidic chip.

[0069] The outermost polyimide membrane passed the test, and the formed pore size was about 5 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com