Device used for punching pipeline

A pipeline and punching technology, which is applied in the direction of feeding device, storage device, positioning device, etc., can solve the problems of untimely waste cleaning, uneven punching force, and affecting the quality of finished products, so as to facilitate the recycling of waste and reduce the impact , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

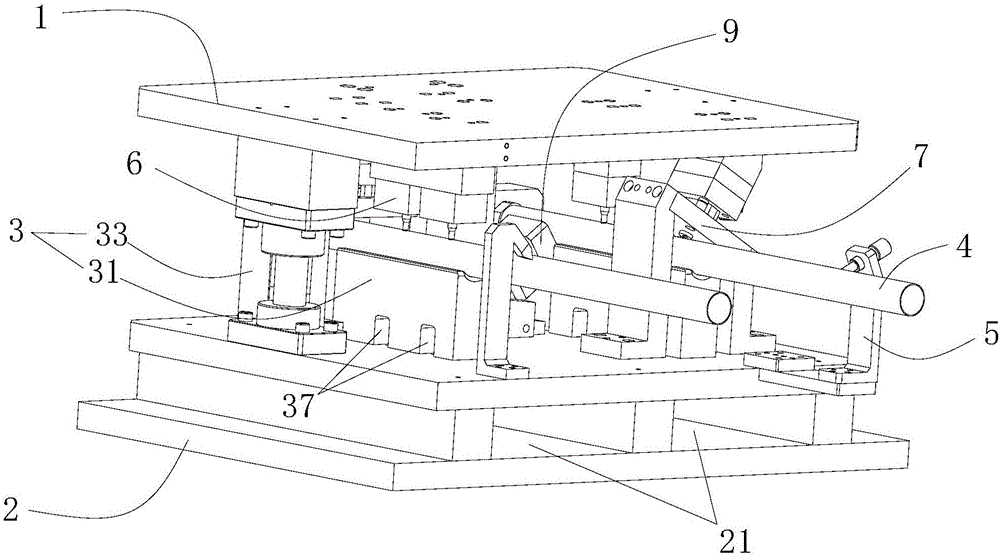

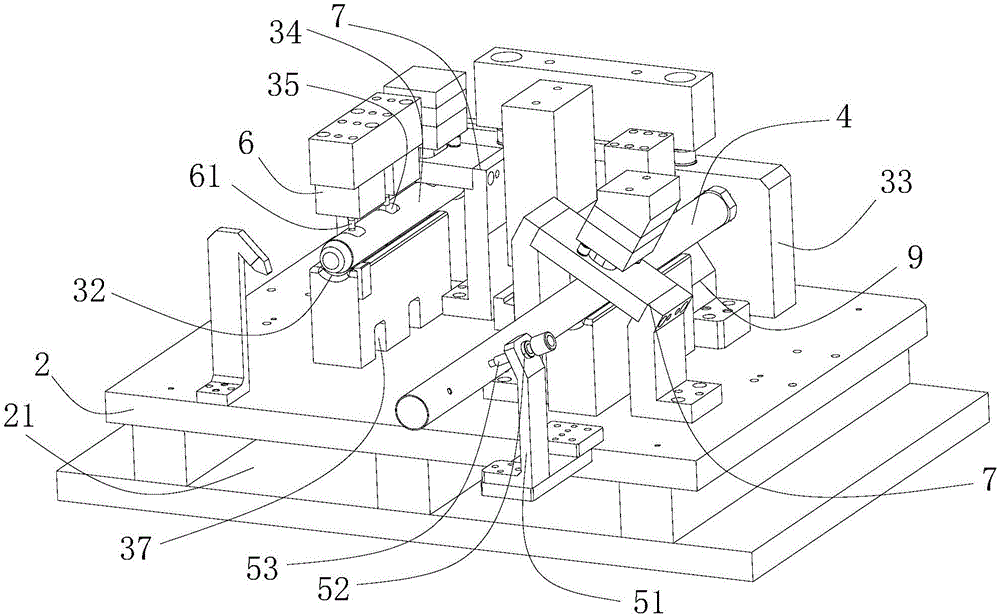

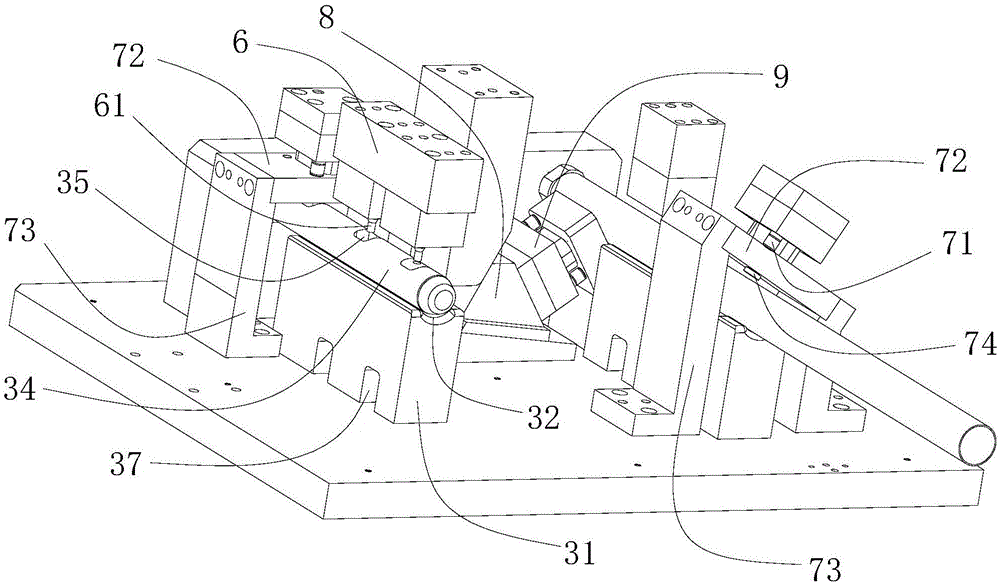

[0026] refer to Figure 1 to Figure 10 , is a device for punching pipes 4, including an upper mold 1 and a lower mold 2 fixed up and down by a support column, the lower mold 2 is provided with a first positioning mechanism 3, and the first positioning mechanism 3 includes a groove 32 on the upper part The base 31, the back seat 33, the splicing rod 34, one end of the splicing rod 34 is fixed on the back seat 33, and the other end is placed in the groove 32 as a free end, and the splicing rod 34 is provided with a hole penetrating along its diameter. Punching groove 35, the base 31 is provided with the waste material passage 36 corresponding to the position of punching groove 35, and the lower mold 2 is provided with the waste material storage space 21 that communicates with waste material passage 36; The outer circumference of the plug rod 34 is pushed into the end of the plug rod 34 located at the rear seat 33, and the pipe 4 is placed in the groove 32; the lower mold 2 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com