Mask plate replacing device and method

A replacement method and mask technology, applied in the field of sputter coating machines, can solve problems such as increased cost, mask failure, wasted time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The problem to be solved by the present invention is how to effectively increase the replacement rate of the mask plate, reduce damage to the mask plate during the replacement process, and improve the coating efficiency. Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

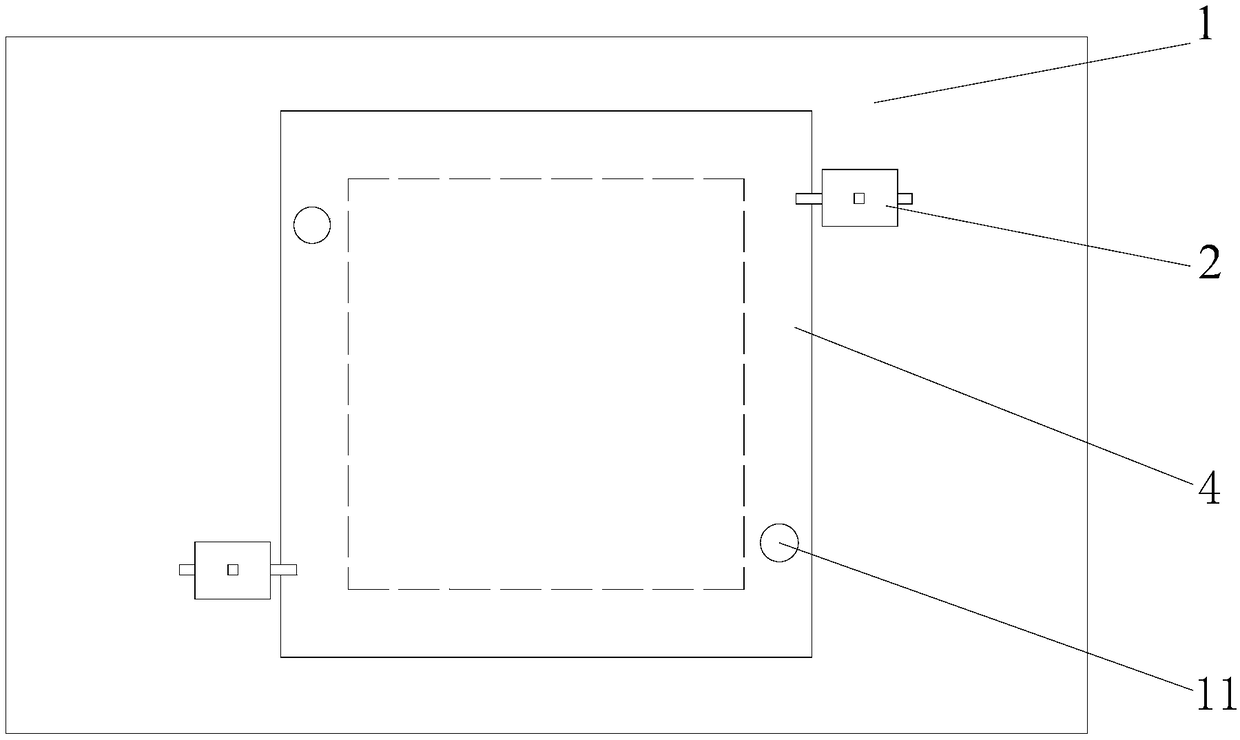

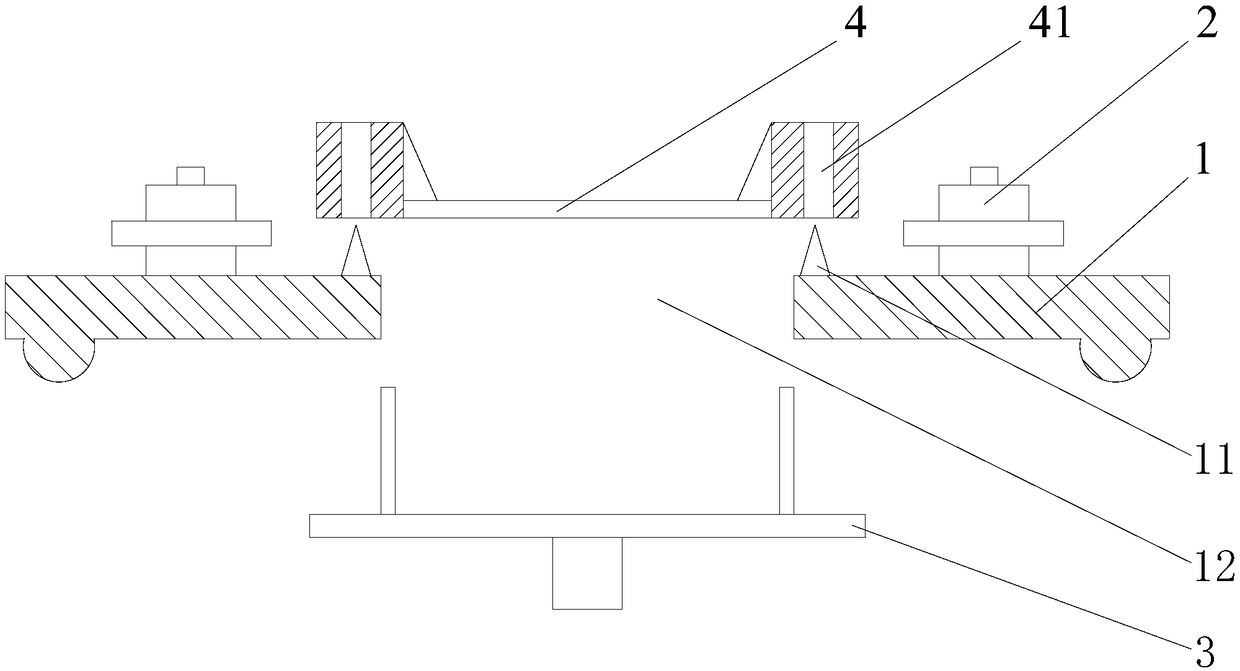

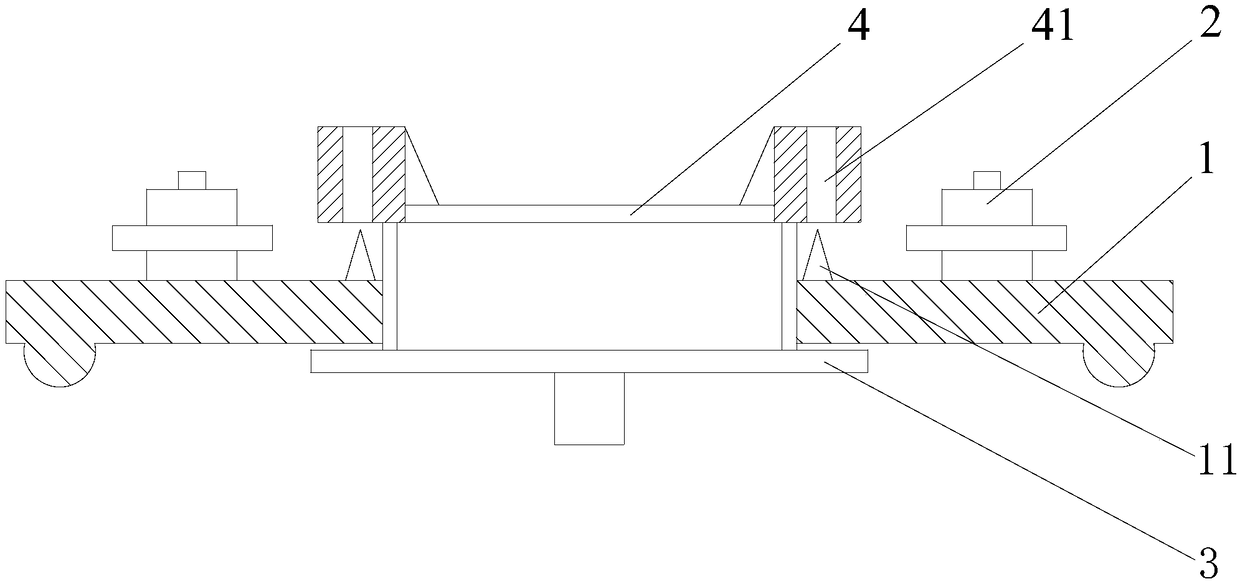

[0029] like Figure 1-4 As shown, the mask replacement device of this embodiment includes a substrate frame 1 for carrying the mask 4, and an automatic locking mechanism 2 arranged on the substrate frame 1 for selectively locking or releasing the mask 4 And be arranged on the tray 3 that is used to hold up mask board 4 under the substrate holder 1, described substrate holder 1 comprises tray hole 12, and described tray 3 can selectively enter and leave described tray hole 12 so that described mask board 4 Lift up or put down, in order to facilitate the replacement of the mask plate, the tray directly passes through the tray hole 12 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com