Gradually-cutting inner hole cutter and machining method

A technology of inner hole and cutter head, which is applied in the direction of cutting blades, metal processing equipment, manufacturing tools, etc., can solve the problems of intermittent impact cutting of inner hole cutting, and achieve the effects of reducing instantaneous displacement, smooth cutting, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

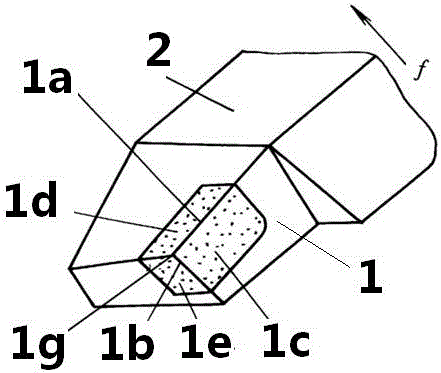

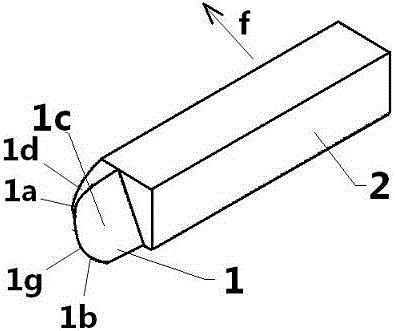

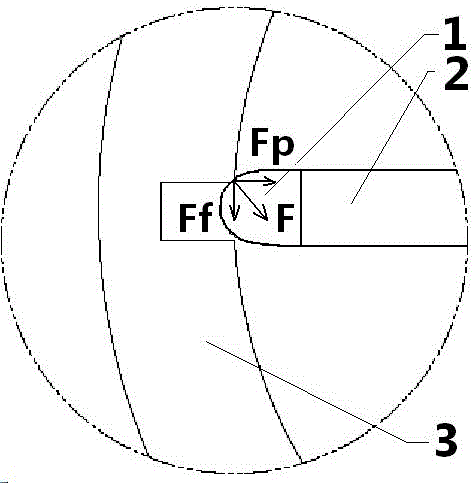

[0013] Examples of the present invention figure 2 , image 3 As shown, it includes a cutter head 1 and arbor 2; the cutter head 1 includes a main cutting edge 1a, a minor cutting edge 1b, a rake face 1c, a main rear face 1d, and a minor rear face 1e; the main cutting edge 1a and the minor cutting edge 1b are respectively An arc; the intersection 1g of the main cutting edge 1a and the minor cutting edge 1b is a smooth arc connection, and there is no inflection point at the intersection 1g between the main cutting edge 1a and the minor cutting edge 1b; the distance between the rake face 1c and the direction of the main cutting force Fc An acute included angle.

[0014] During cutting, the arc-shaped main cutting edge 1a gradually contacts the irregular part of the inner hole of the workpiece; because the inner surface of the workpiece is in contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com