Rotary pressure reducing valve

A pressure reducing valve and rotary technology, applied in the field of pressure reducing valves, can solve the problems of affecting downstream pressure regulation, unreliable sealing, easy damage to the sealing surface, etc., and achieve the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

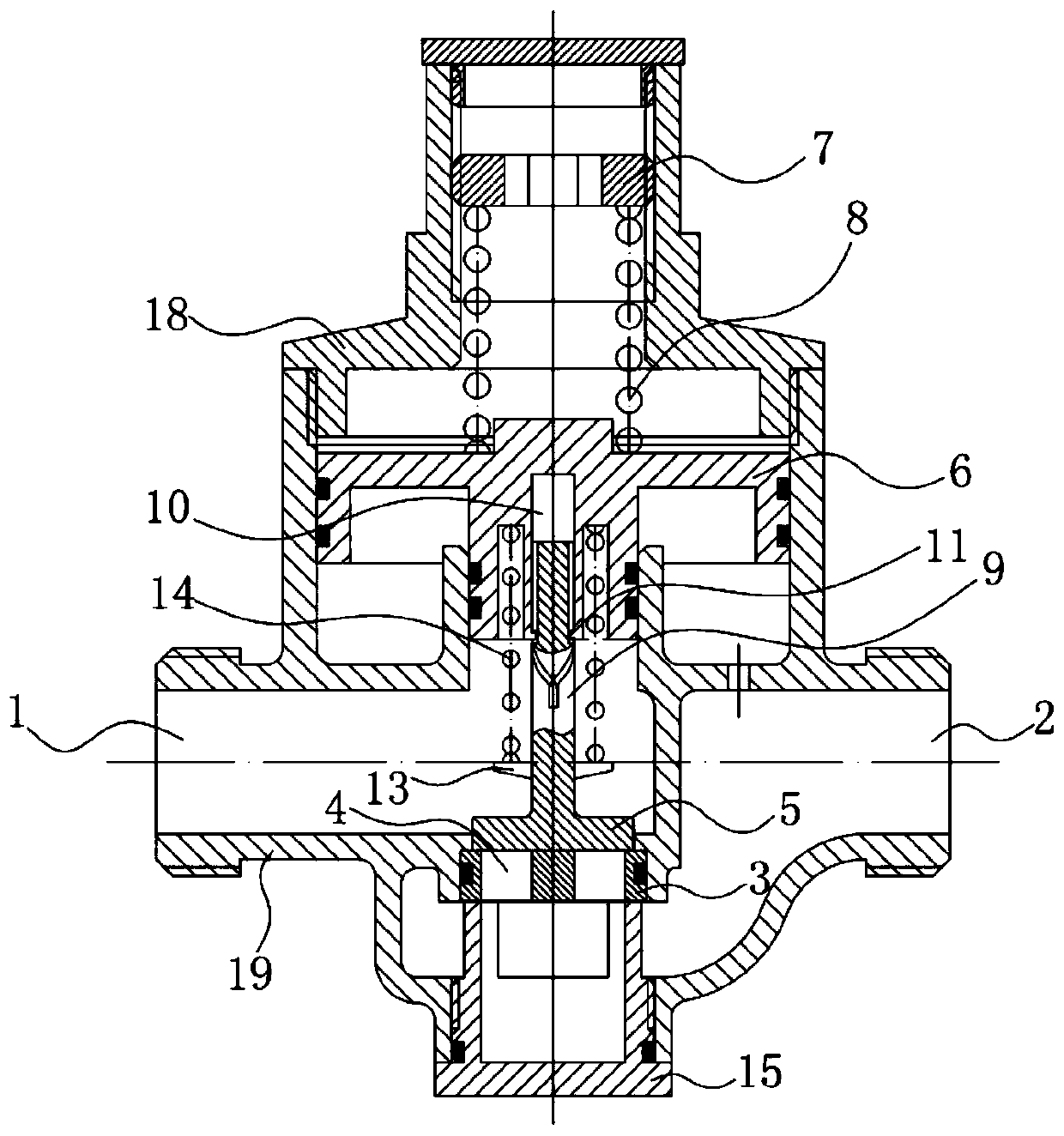

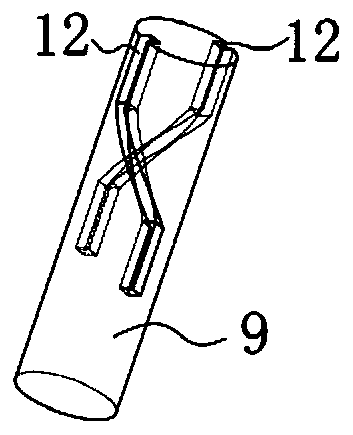

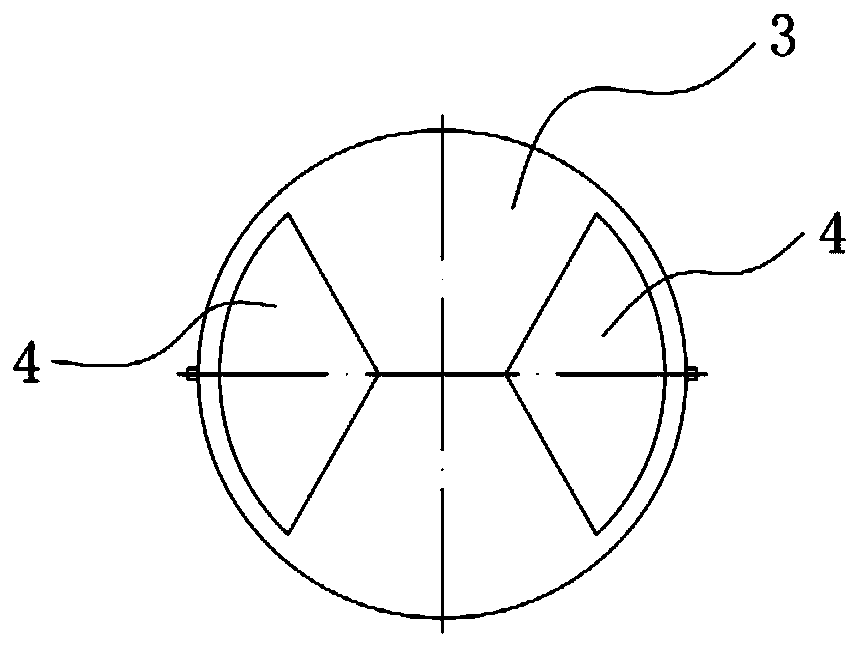

[0027] Such as figure 1 As shown, this embodiment proposes a rotary pressure reducing valve, including a pressure regulating assembly arranged between the inlet 1 and the outlet 2 of the pressure reducing valve, and a fixed seat 3 is arranged in the pressure reducing valve, between the inlet 1 and the outlet 2 Through the opening 4 on the fixed seat 3, the pressure adjustment component is connected with a reversing structure, and the reversing structure is connected with a rotary valve plate 5. The pressure change of the outlet 2 changes the position of the pressure regulating component, so that the reversing structure drives the rotary valve. When the plate 5 rotates, the rotary valve plate 5 cooperates with the fixed seat 3 , and the area of the opening 4 can be changed during the rotation of the rotary valve plate 5 .

[0028] The rotary pressure reducing valve transforms the original method of changing the size of the flow channel area and stabilizing the pressure at the...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is: as Image 6 As shown, the direction changing structure is a crank connecting rod structure, including a connecting rod 16 and a crank 17. The connecting rod 16 is connected to the pressure regulating assembly, and the crank 17 is connected to the rotary valve plate 5. The length direction of the crank 17 and the length direction of the connecting rod 16 are Fitted at 90°.

[0039] The rotary pressure reducing valve changes the flow area through rotary motion. In addition to the structures of Embodiments 1 and 2, the gear and rack transmission mode, the multi-point connecting rod mode or the magnetic field mode can also be selected to realize the rotation of the rotary valve plate 5. According to Specific needs to be selected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com