Method for replacing test section of continuous transonic wind tunnel

A replacement method and transonic technology, applied in aerodynamic tests, machine/structural component testing, measuring devices, etc., can solve problems such as gas waste in continuous transonic wind tunnels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

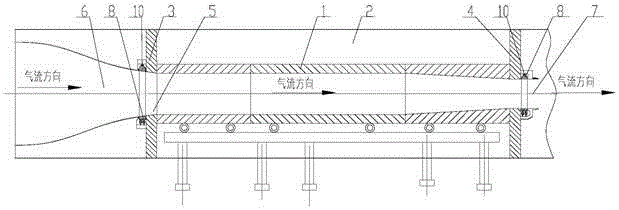

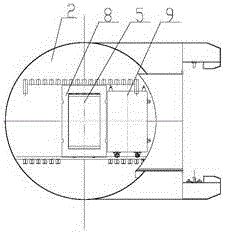

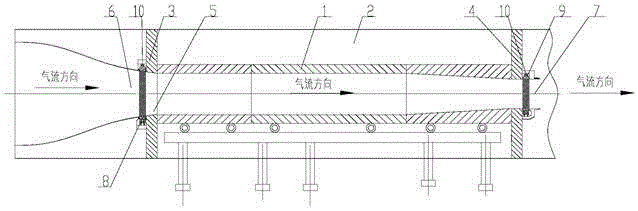

[0012] See attached Figure 1~4 As shown in the test section replacement method of this kind of continuous transonic wind tunnel, the test section 1 of the continuous transonic wind tunnel is located in the inner center of the chamber 2 of the continuous transonic wind tunnel, and the two ends of the chamber 2 are respectively arranged There are a front load-bearing wall 3 and a rear load-bearing wall 4, and there are respectively test flow channels 5 on the front load-bearing wall 3 and the rear load-bearing wall 4. The outflow side 7 of the force wall 4 is respectively provided with a diversion door 8 for flow diversion and an isolation door 9 for flow interception. The diversion door 8 and the isolation door 9 are installed on a guide rail 10. When the continuous transonic wind When the hole is in the working state, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com