Fatigue durability test method for gear selection and shift mechanism of transmission

A technology of fatigue durability and test method, which is applied in the field of fatigue durability test of transmission gear selection mechanism and fatigue durability test of gear selection mechanism, which can solve the problem of qualitative and quantitative evaluation of fatigue durability of transmission selection and shift mechanism, and can not obtain the corresponding structure. Problems such as the decline of bearing capacity, to achieve the effect of reliable working principle, high simulation accuracy, and improved reliability design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

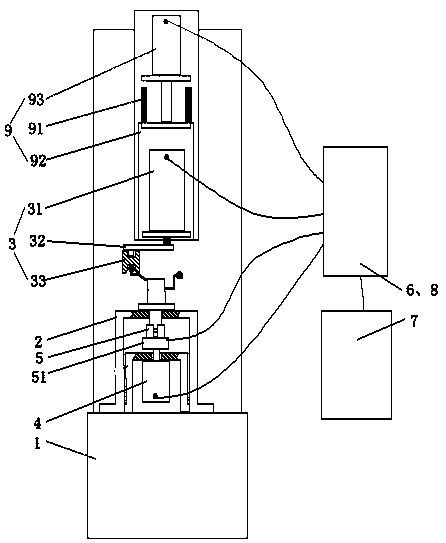

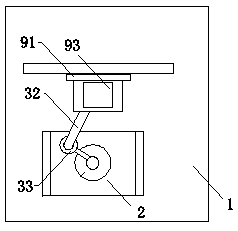

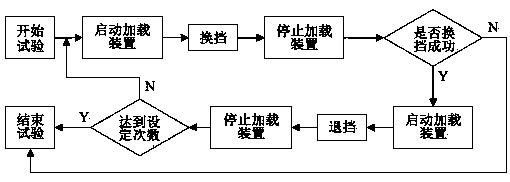

[0024] During specific implementation: if Figure 1 ~ Figure 2 As shown, a transmission selection and shifting mechanism fatigue endurance test system includes a base 1, and the base 1 is provided with a mounting frame 2 for fixedly installing the selection and shifting mechanism to be tested, and a shifting mechanism for operating the selection and shifting mechanism. The shifting operating mechanism 3 of the gear arm rotation; also includes a loading device 4 for applying a load force to the shift finger of the selected shifting mechanism to be tested, and the output end of the loading device 4 is provided with a The gear shift finger matched with the gear shift finger holder 5, and the angular displacement for detecting the rotation angle of the shift finger of the gear shift mechanism is installed between the shift finger holder 5 and the output end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com