High temperature electrical capacitance tomography sensor and production method thereof

A technology of capacitance tomography and sensors, which is applied in the direction of material capacitance, etc., to achieve the effect of optimizing the manufacturing process, solving the difficulty of electrode layout, and expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

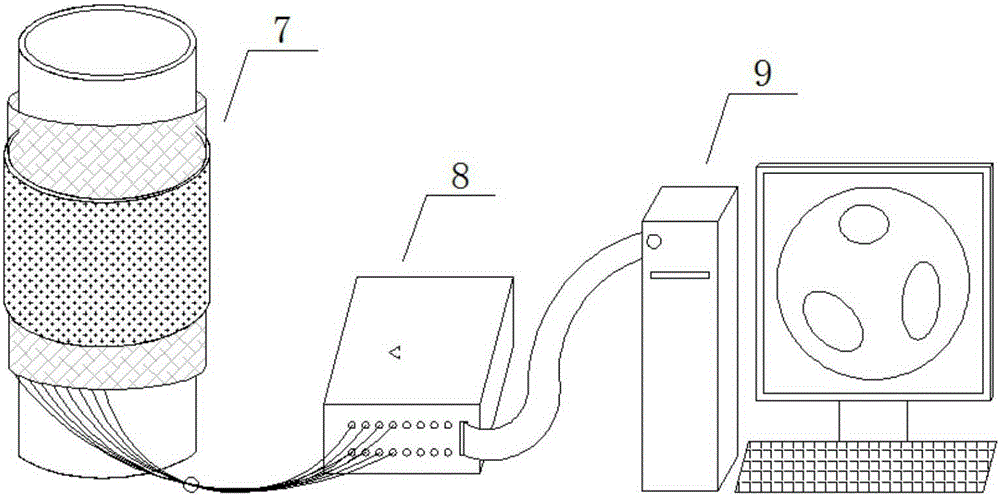

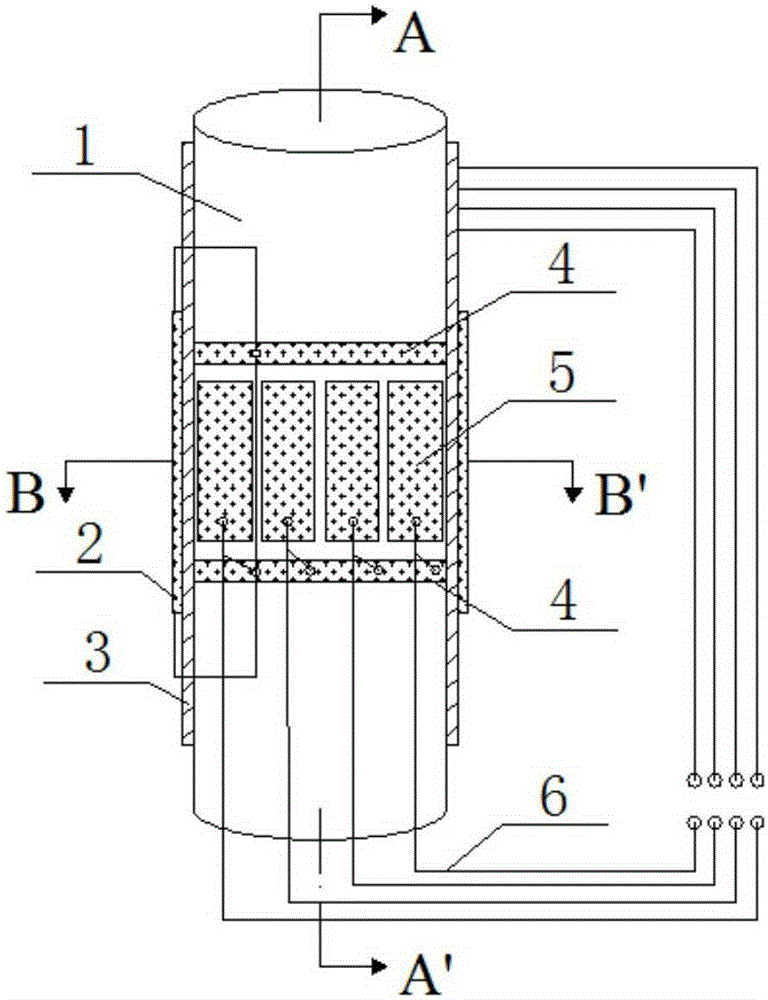

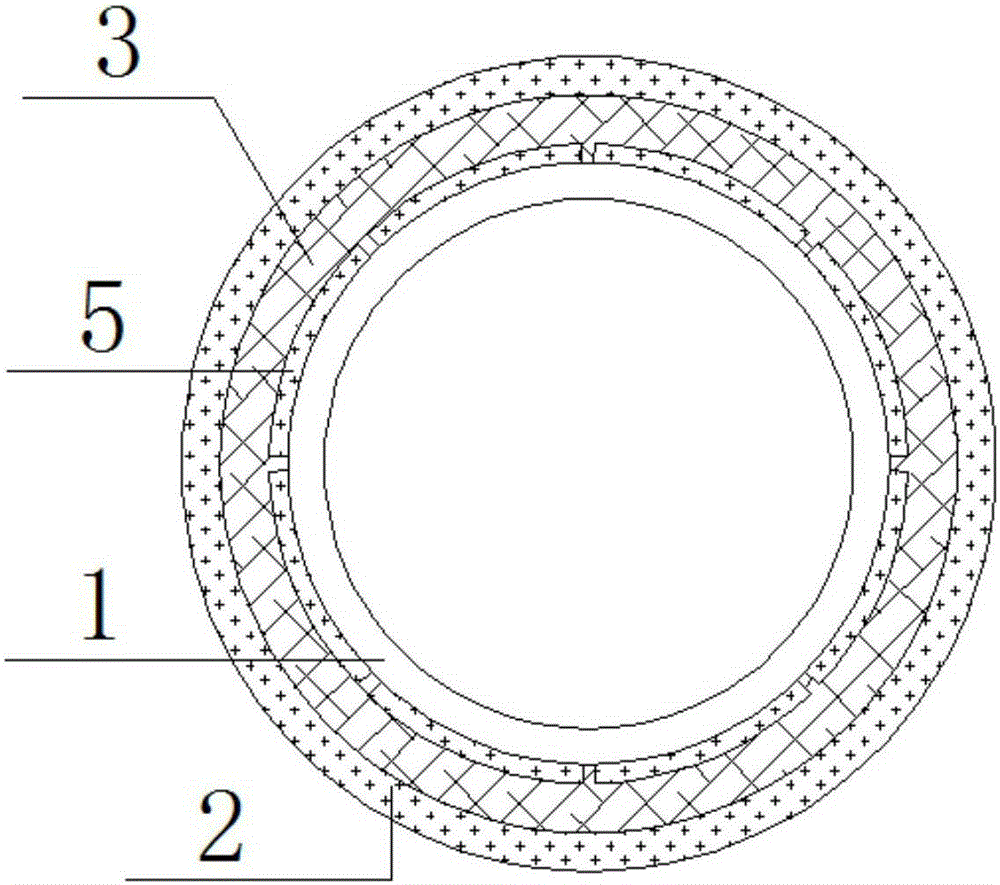

[0038] Aiming at the necessity and limitations of high-temperature fluidization process measurement, the present invention designs an electrical capacitance tomography sensor applied in a high-temperature environment, which can respond to the multi-phase medium in the sensor measurement area within a temperature range of 300°C. distribution, and realize two-dimensional visualization.

[0039] Specifically, the present invention provides an electrical capacitance tomography sensor applied in a high temperature environment, the sensor includes an array distributed measurement electrode resistant to a high temperature of 300°C, a shaft end shield electrode, a high temperature resistant insulating isolation layer, an outer shield and a signal Transmission cable; the 300°C high temperature resistant array distribution electrode includes N (8 to 16) measuring electrodes of the same size or size; the signal transmission line includes a cable core, an insulating layer and a shielding w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com