An automatic exporting device for multi-directional magnetic steel sheets

A technology of exporting device and magnetic steel sheet, which is applied in the direction of electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems of low assembly efficiency, missing and reversed assembly of magnetic steel sheets, and achieves improved assembly quality and high assembly. , The effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

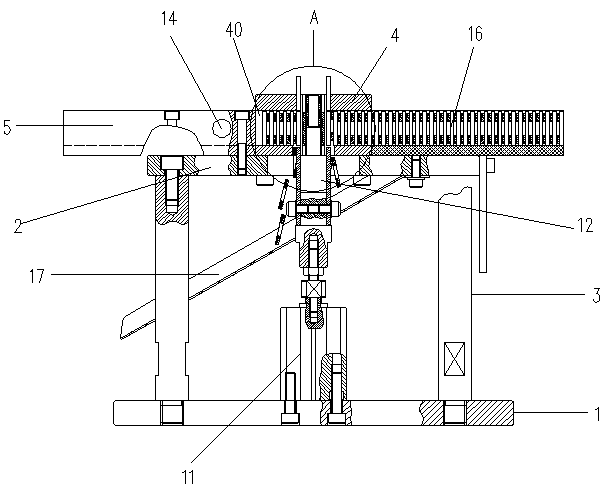

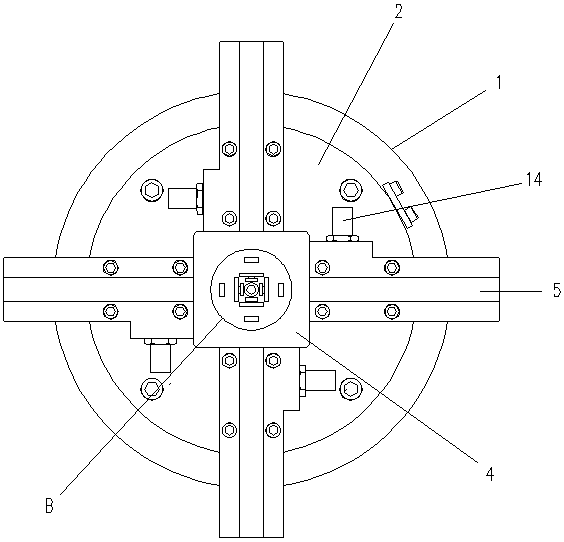

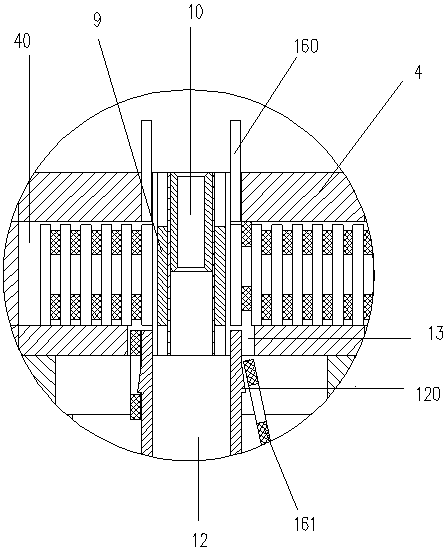

[0022] Such as figure 1 and figure 2 A multi-directional automatic exporting device for magnetic steel sheets is shown, including a base 1 and a base plate 2 parallel to the base. The bottom surface of the base plate is connected to the base through a support column 3, and the center of the top surface of the base plate 2 is provided with a magnetic steel sheet exporting positioning seat 4. The four sides of the magnetic steel sheet lead-out positioning seat are provided with feeding channels 40, and the top surface of the substrate 2 is provided with four feeding rails 5 for feeding the magnetic steel sheet strips 16, and the four feeding rails are distributed in a cross shape , the inner ends of the four feed rails are connected to the four feed channels one by one, and the top surface of the magnetic steel sheet lead-out positioning seat 4 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com