Preparation method and application of organic isocyanate-and-isorhodanate modified attapulgite

A technology for modifying attapulgite and isothiocyanate, which is applied in chemical instruments and methods, silicate, aluminum silicate, etc., can solve the problems of restricting the application of attapulgite, and achieve a simple preparation method, which is beneficial to The effect of popularization and use and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The embodiment of the present invention provides a method for preparing organic isocyanate and isothiocyanate modified attapulgite, comprising the following steps:

[0026] S1. Add attapulgite raw soil through a 100-300 mesh sieve into the reactor, and add 3-4mol / L of HCl or HNO 3 After soaking 20-50mL for 24h, wash with deionized water until neutral, and dry at 105°C-120°C.

[0027] S2. Weigh 200 mg of the pretreated and dried attapulgite obtained in step S1 and place it in an ethanol solution, and add about 0.45 mmol-1.0 mmol of 3-aminopropyltrimethoxysilane. Stir for 3-6h in the temperature range of -8°C-40°C. Filter and wash, and dry at 105°C-120°C.

[0028] S3. Add 0.46-1 mmol isocyanate and isothiocyanate ethanol solution to the ethanol solution of attapulgite obtained in step S2, reflux and stir at a temperature of about 80°C for 1-5h, filter, wash, and vacuum dry at about 85°C Obtain organic isocyanate and isothiocyanate modified attapulgite.

[0029] In ste...

Embodiment 1

[0043] (1) Pretreatment of attapulgite. Add 5g of attapulgite raw soil passed through a 200-mesh sieve into the reactor, add 30mL of 3-4mol / L HCl, soak for 24h, wash with deionized water until neutral, and dry at 105°C.

[0044] (2) Weigh 200 mg of pretreated and dried attapulgite and place it in 20 mL of ethanol solution, and add about 0.45 mmol of 3-aminopropyltrimethoxysilane. Stir internally for 4 h at a temperature of 10 °C. Filter washed and dried at 105°C.

[0045] (3) Add 0.45-1 mmol ethanol solution of p-nitrophenylisocyanate to 200 mg of the product obtained in (2), and reflux and stir at about 80° C. for 2 h. Filtrate, wash, and vacuum-dry at about 85°C to obtain p-nitrophenylisocyanate-modified attapulgite.

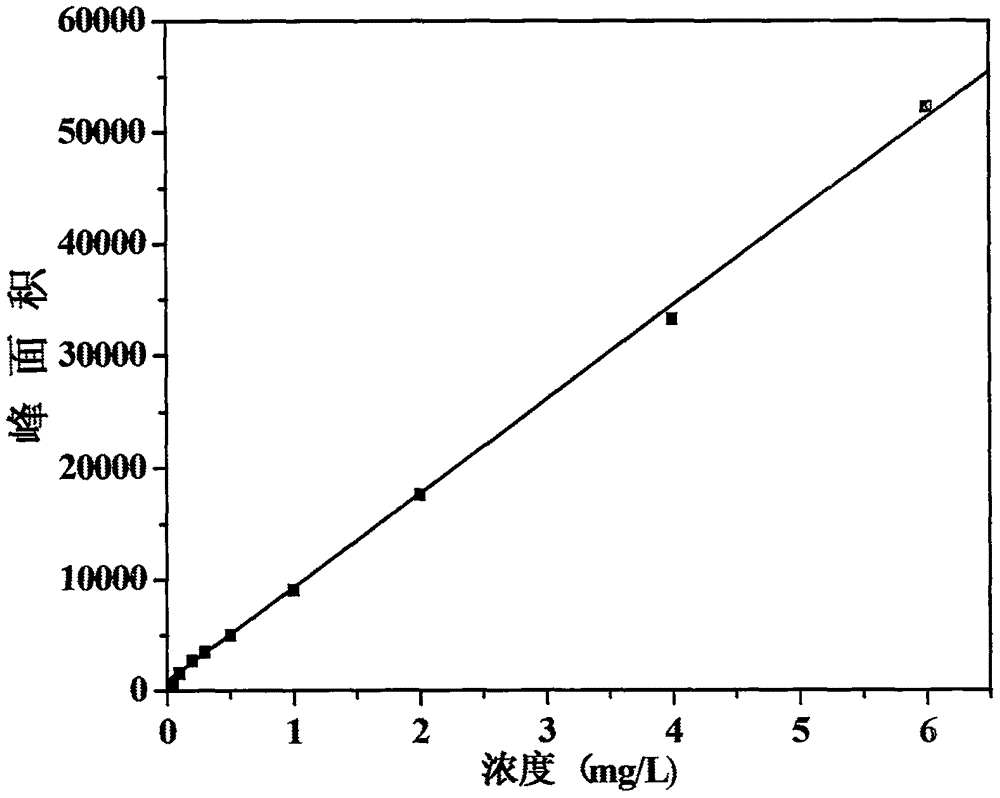

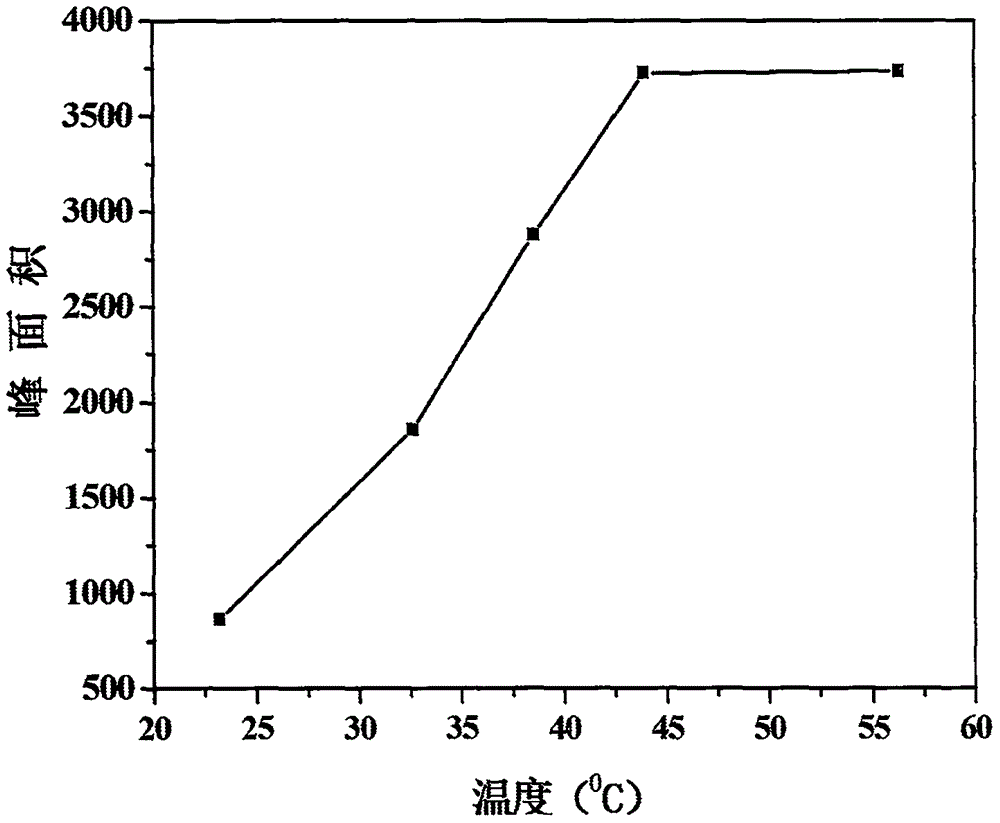

[0046] (4) Determine the chromatographic working conditions. Select chromatographic column: Inertisil-ODS-SP C18, 4.6×150mm, 5 μm, mobile phase is acetonitrile:water=20:80 (V / V), flow rate 1.00mL min -1 , column temperature 25°C, UV detection wavelength: ...

Embodiment 2

[0052] (1) Pretreatment of attapulgite. Add 5g of attapulgite raw soil through a 200-mesh sieve into the reactor, add 3-4mol / L of HNO 3 After soaking 30mL for 24h, wash with deionized water until neutral, and dry at 105°C.

[0053] (2) Weigh 200 mg of pretreated and dried attapulgite into 20 mL of ethanol solution, and add about 0.6 mmol of 3-aminopropyltrimethoxysilane. Stir internally at 10 °C for 3 h. Filter washed and dried at 105°C.

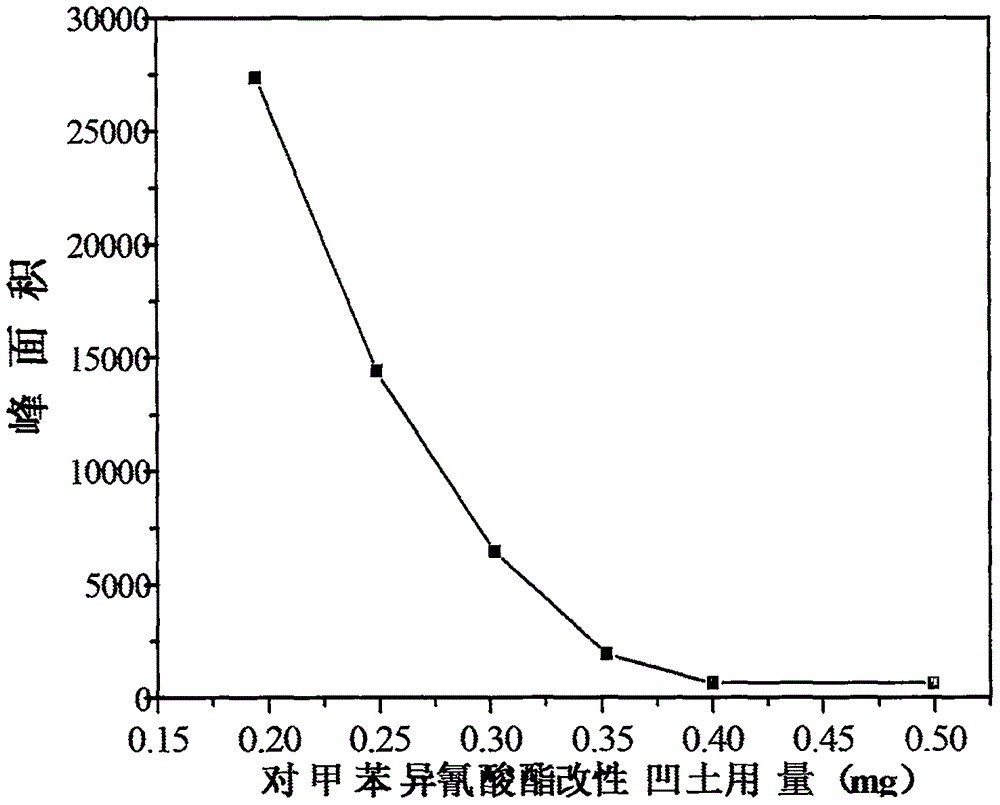

[0054] (3) Add 1 mmol ethanol solution of p-toluene isocyanate to 200 mg of the product obtained in (2), and stir under reflux at a temperature of about 80° C. for 2 h. Filtrate, wash, and vacuum-dry at about 85°C to obtain p-toluene isocyanate-modified attapulgite.

[0055] (4) Determine the chromatographic working conditions. Select chromatographic column: Inertisil-ODS-SP C18, 4.6×150mm, 5 μm, mobile phase is acetonitrile:water=20:80 (V / V), flow rate 1.00mL min -1 , column temperature 25°C, UV detection wavelength: 254nm, injection ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap