Monolithic plate-type swing rod

A plate-type, single-body technology, applied in household appliances, sanitary equipment, applications, etc., can solve the problems of affecting the flexibility of seat cushion swing, violent collision between the seat cushion and the upper cover, and the seat cushion cannot be fully opened, so as to prevent violent impact and simplify assembly. , the effect of structure simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

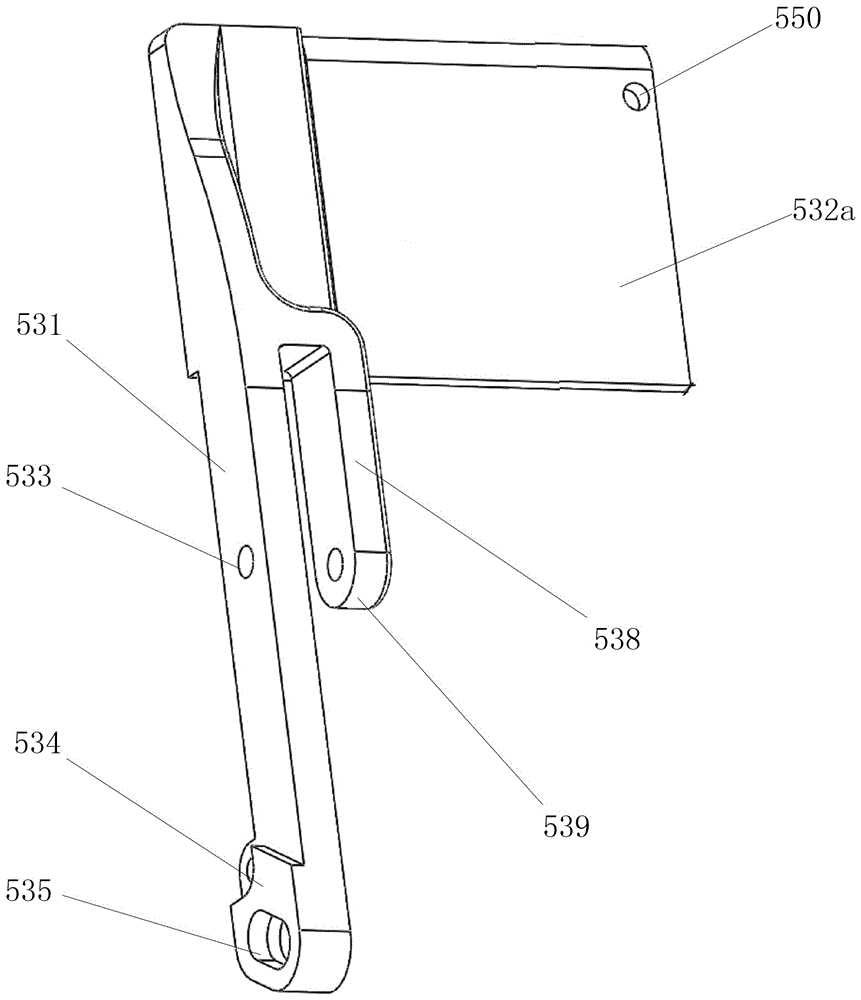

[0023] Embodiment 1: see figure 1 , the first kind of single plate type swing rod, the swing rod is a parallel double rod structure, the length of one rod is longer than the length of the other rod; The middle part of the rod is provided with a swing rod central axis hole, the rear end of the long rod is provided with a swing rod traction head; the short rod rear end is provided with a short rod shaft hole, and the short rod shaft hole is coaxial with the swing rod central shaft hole; The end of the rear end of the short rod is an arc surface, and the arc surface is concentric with the shaft hole of the short rod.

[0024] A spare traction hole is arranged on the transverse plate at the front end of the swing rod, and the spare traction hole is connected with the fixing belt.

[0025] The pendulum pulling head is provided with a stopper embedding hole, and a wire slot is arranged in the middle of the stopper embedding hole.

[0026] The shaft is fixed on the inner shell and ...

Embodiment 2

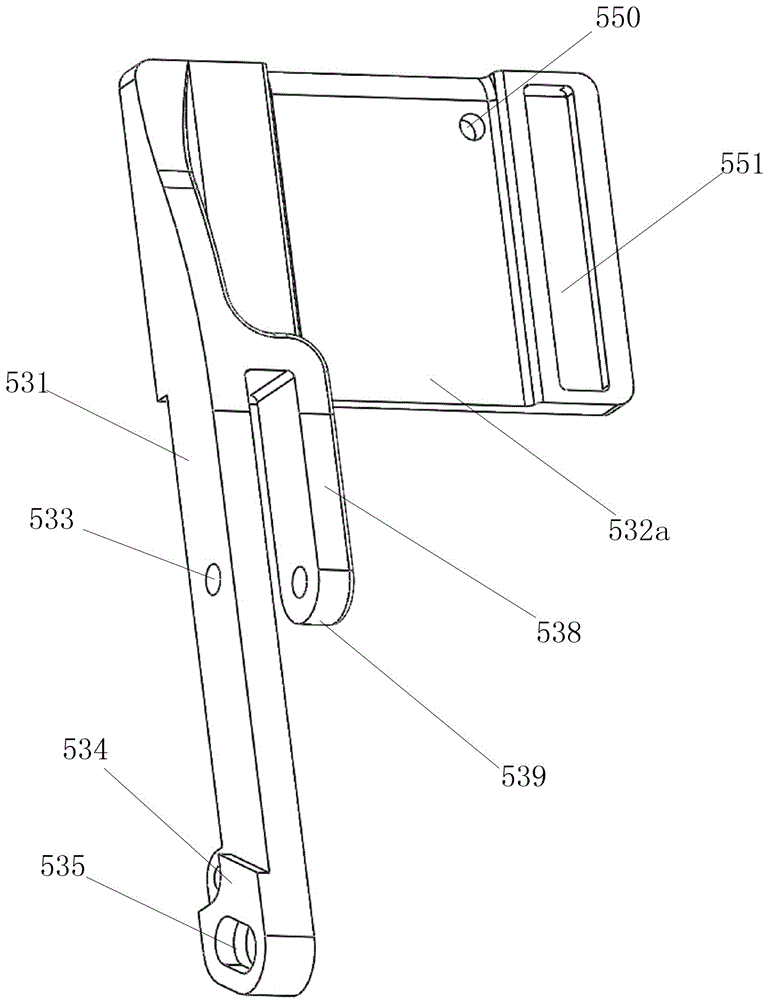

[0028] Example 2: see figure 2 and Figure 4 , the second kind of single plate type swing rod, the side of the front end of the swing rod is provided with a fixing belt sliding hole, and the fixing belt is located in the fixing sliding hole.

Embodiment 3

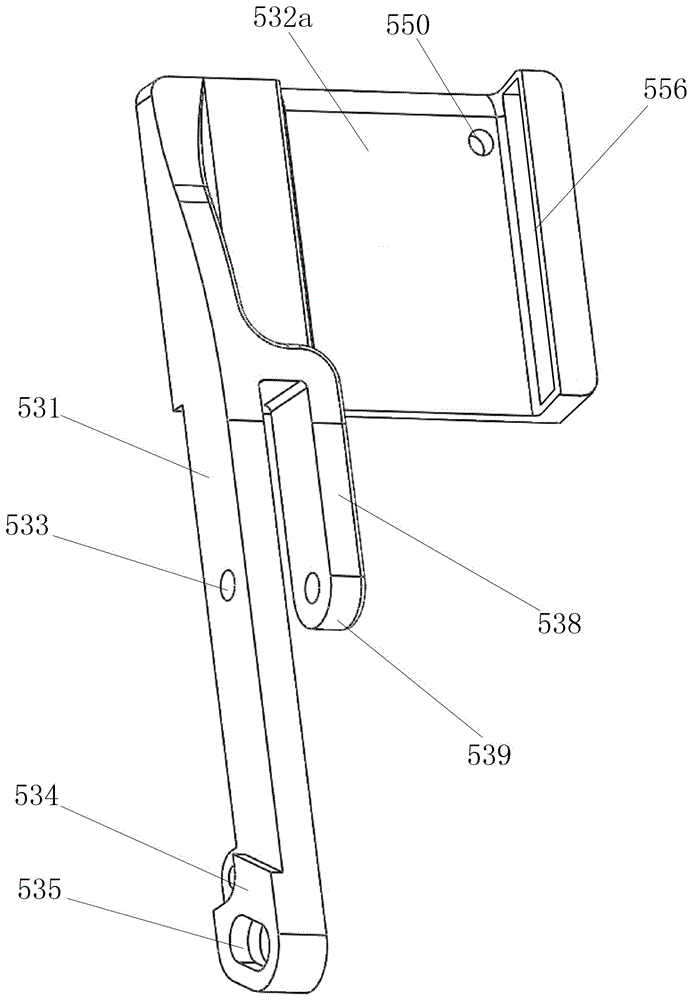

[0029] Embodiment 3: see image 3 , the third one shows the single plate type swing rod, the side of the front end of the swing rod is provided with a positioning chute, the positioning chute is matched with a slider that can only move longitudinally, and the slider is provided with a fixed belt jack, the fixing band is installed in the fixing band jack.

[0030] Explanation: The drawings of the above embodiments are schematic diagrams, and their dimensions do not completely match the outline of the seat cushion. In the case of keeping the overall structural relationship unchanged, the partial dimensions can be adjusted appropriately to make it match the toilet and seat cushion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com