Capacity Controlled Rotary Compressor

A rotary compressor and capacity control technology, which is applied in the direction of rotary piston machines, rotary piston pumps, mechanical equipment, etc., can solve the problems of high difficulty in application technology, high cost, and increased reliability of electronic components, and achieve improved Effects of production efficiency, miniaturization of shape, and ease of introduction into industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0068] Hereinafter, the form of the first embodiment of the present invention will be described based on the drawings.

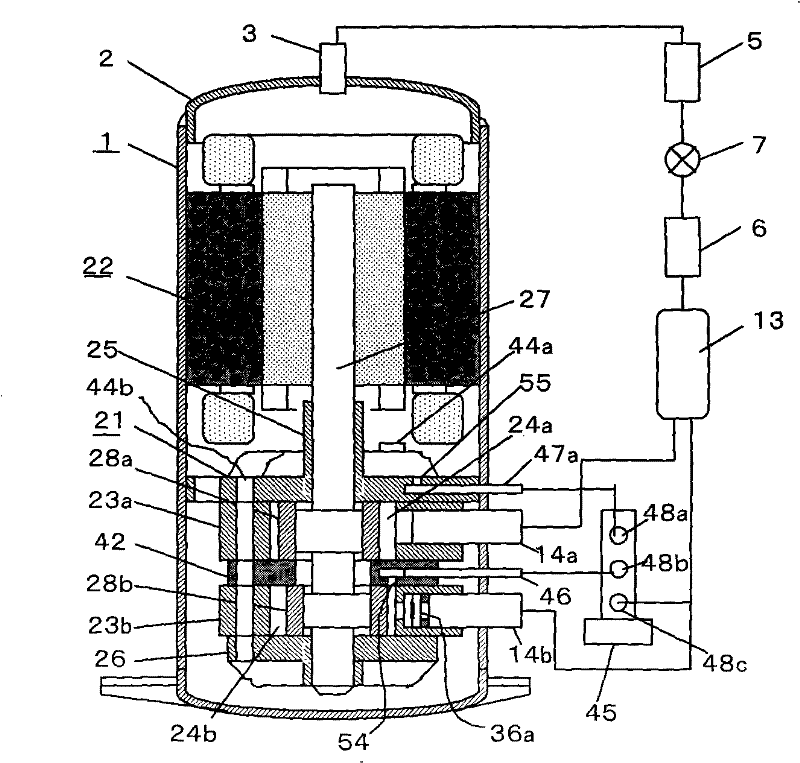

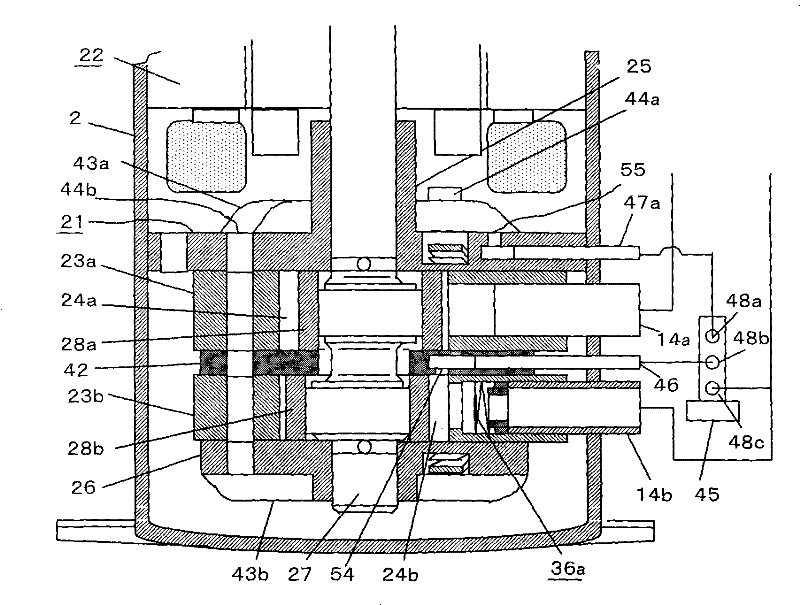

[0069] figure 1 and figure 2 , showing the internal structure of the capacity-controlled rotary compressor and the refrigeration cycle equipped with the compressor. The capacity-controlled rotary compressor is simply referred to as the rotary compressor 1 .

[0070] The rotary compressor 1 is composed of a compression unit 21 installed on the inner diameter of the sealed casing 2 and a motor 22 arranged on the upper part. The compression assembly 21 has two cylinders---the first cylinder 23a and the second cylinder 23b, which are divided by the middle plate 42 to form the first cylinder compression chamber 24a and the second cylinder compression chamber 24b respectively.

[0071] In the first embodiment, the displacement of the second cylinder 23b is small relative to the displacement of the first cylinder 23a. If the sum of the displacements of the two...

no. 2 example

[0104] In the first embodiment, the opening of the first high-pressure output pipe 47a is arranged inside the muffler. In the second embodiment, as Figure 7 As shown, the second high-pressure output pipe 47b is opened inside the sealed casing 2, so the pressure difference Δp between the second high-pressure output pipe and the sealed casing 2 is zero.

[0105] Therefore, it is necessary to carry out a new means of receiving and holding the slide in the slide groove. The pressure switching hole 54 disposed at the tip of the cylinder pressure switching pipe 46 is opened between the second cylinder compression chamber 24b and the first one-way valve device 36a as in the first embodiment.

[0106] In this embodiment, there is still a first one-way valve device 36a, which is arranged at the opening of the second suction pipe 14b located in the compression chamber of the second cylinder, and has nothing to do with the second sliding plate 29b.

[0107] A recess is provided on the ...

no. 3 example

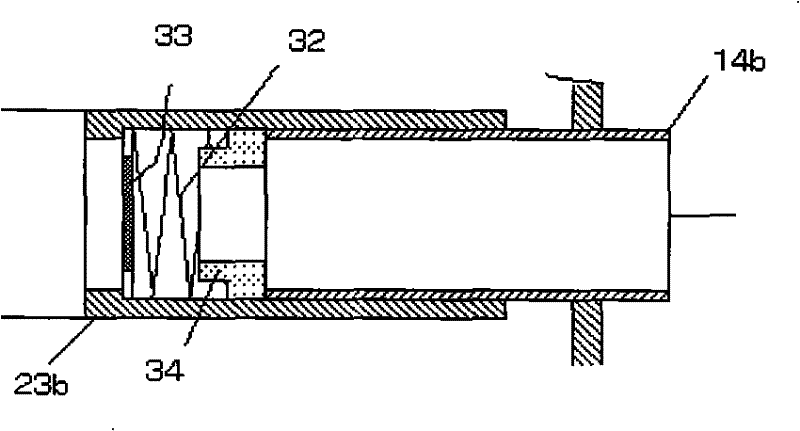

[0115] Such as Figure 9 As shown, the third embodiment, compared with the first embodiment, omits the second suction pipe 14b, and is designed to connect the second check valve device 36b from the first suction pipe 14a to the suction of the first cylinder compression chamber 24a. In the middle of the gas passage, the branch passage 37 of the second cylinder 23b is branched. The second one-way valve device 36b, such as Figure 9 As shown, it is desirable to configure the branch passage 37 designed in the intermediate plate 42 .

[0116] The second one-way valve device 36b consists of the valve seat 34 processed on the branch passage 37, the one-way valve 33, and the coil spring 32 that always presses the one-way valve 33 to the side of the stopper 35 between the two, This is constituted by a stop 35 formed by the planar portion of the second cylinder 23b.

[0117] In the passage from the branch passage 37 to the second cylinder compression chamber 24b, the cylinder pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com